Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 688

Note

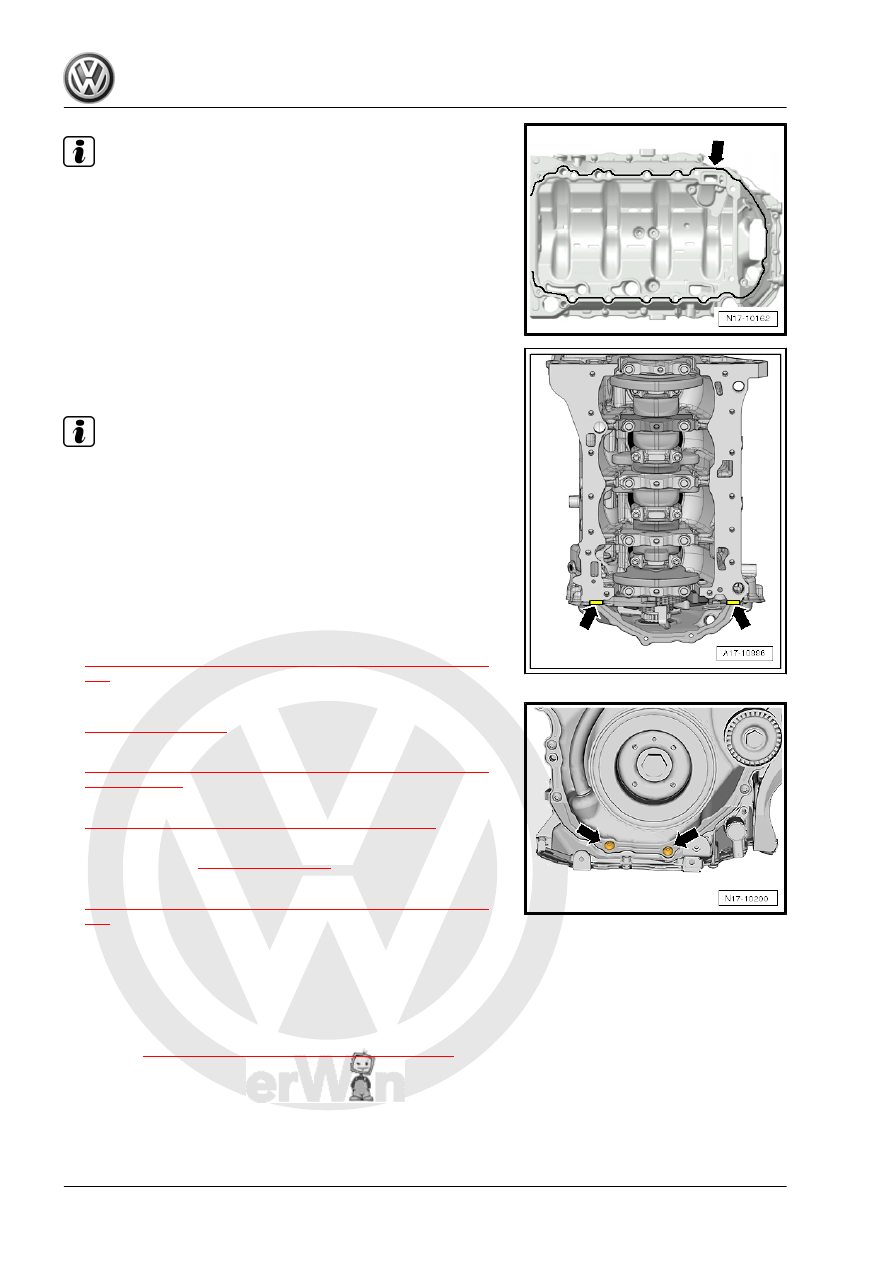

The lubrication system could be plugged with excess sealant. Do

not apply sealant bead thicker than indicated.

– Apply the silicone sealant on the clean sealing surface of the

upper oil pan section as shown -arrows-.

• Sealant bead thickness: 2 to 3 mm.

– Apply the silicon sealant, as shown in the illustration

-arrows-, between the cylinder block and the timing chain

guard lower section.

Note

♦

The oil pan upper section must be installed within 5 minutes

after application of silicone sealant.

♦

The sealant bead may not be thicker than specified, otherwise

excess sealant could enter the oil pan and clog the oil intake

tube.

• On the transmission side, the upper part of the oil pan and the

crankcase must align.

– Position the upper section of the oil pan immediately and tight‐

en the bolts, tightening sequence. Refer to Tightening se‐

quence. Refer to

⇒ Fig. ““Oil Pan Upper Section - Tightening Sequence”“ , page

.

– Install the bolts -arrows-. Tightening specifications -item 16-

– Install the rear sealing flange. Refer to

⇒ “2.3 Sealing Flange, Removing and Installing, Transmission

– Install the oil pump. Refer to

⇒ “1.5 Oil Pump, Removing and Installing”, page 188

– Insert the new oil baffle and attach it. Tightening specification.

Refer to -item 7-

– Install oil pan lower section. Refer to

⇒ “1.3 Oil Pan Lower Section, Removing and Installing”, page

.

Assemble in reverse order of disassembly.

– Fill with engine oil and then check the level. Refer to ⇒ Main‐

tenance ; Booklet 36.1 ; Procedure Descriptions; Engine Oil,

Draining, Replacing Oil Filter, and Filling .

Tightening Specifications

♦ Refer to

⇒ “1.1 Overview - Oil Pan/Oil Pump”, page 179

.

1.5

Oil Pump, Removing and Installing

Special tools and workshop equipment required

♦ Elbow Assembly Tool - T10118-