Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 689

2

Engine Oil Cooler

⇒ “2.1 Overview - Engine Oil Cooler”, page 192

⇒ “2.2 Engine Oil Cooler, Removing and Installing”, page 192

⇒ “2.3 Mechanical Switch Valve, Removing and Installing”, page

2.1

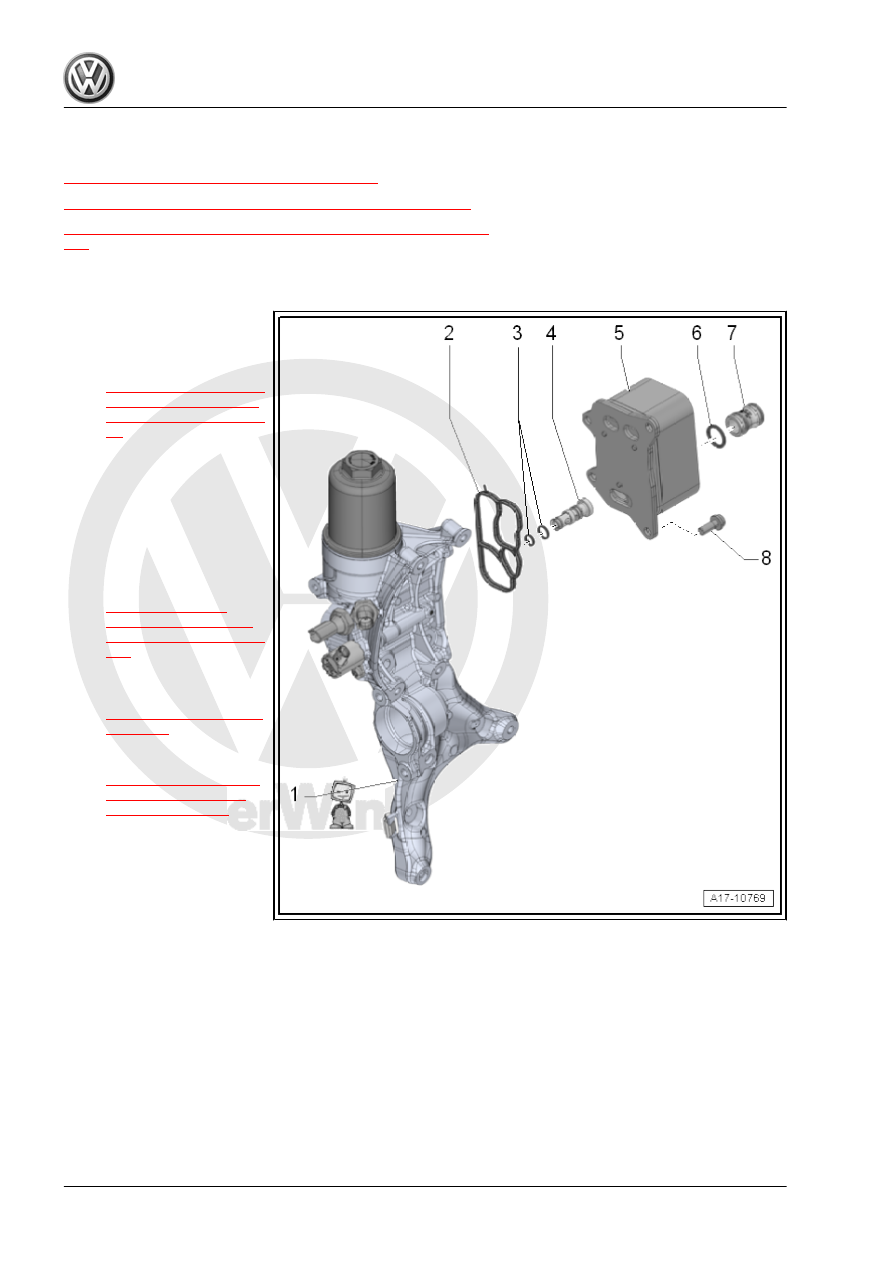

Overview - Engine Oil Cooler

1 - Auxiliary Components

Bracket

❑ Removing and instal‐

ling. Refer to

2 - Seal

❑ Replace after removing

3 - O-Rings

❑ Replace after removing

❑ Coat with engine oil

4 - Mechanical Switch Valve

❑ Replacing. Refer to

.

5 - Engine Oil Cooler

❑ See note. Refer to

❑ Removing and instal‐

ling. Refer to

6 - Seal

❑ Replace after removing

❑ Coat with coolant

7 - Connection

8 - Bolt

❑ 8 Nm + 45° turn

❑ Replace after removing

2.2

Engine Oil Cooler, Removing and Instal‐

ling

Special tools and workshop equipment required

♦ Shop Crane - Drip Tray - VAS6208-