Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 687

♦ Hand Drill with Plastic Brush Attachment

♦ Protective Eyewear

♦ Silicone sealant. Refer to Parts Catalog.

Caution

This procedure contains mandatory replaceable parts. Refer

to component overview prior to starting procedure.

Mandatory Replacement Parts

♦ Bolts - Oil Pan

♦ Bolt - Oil Baffle

♦ Gasket - Drain Plug

♦ Oil Baffle

Note

There are plastic ribs on the oil baffle that deform permanently

when tightening the oil pan lower section. The plastic ribs ensure

the oil baffle has no play and does not rattle. Because of this,

always replace the oil baffle.

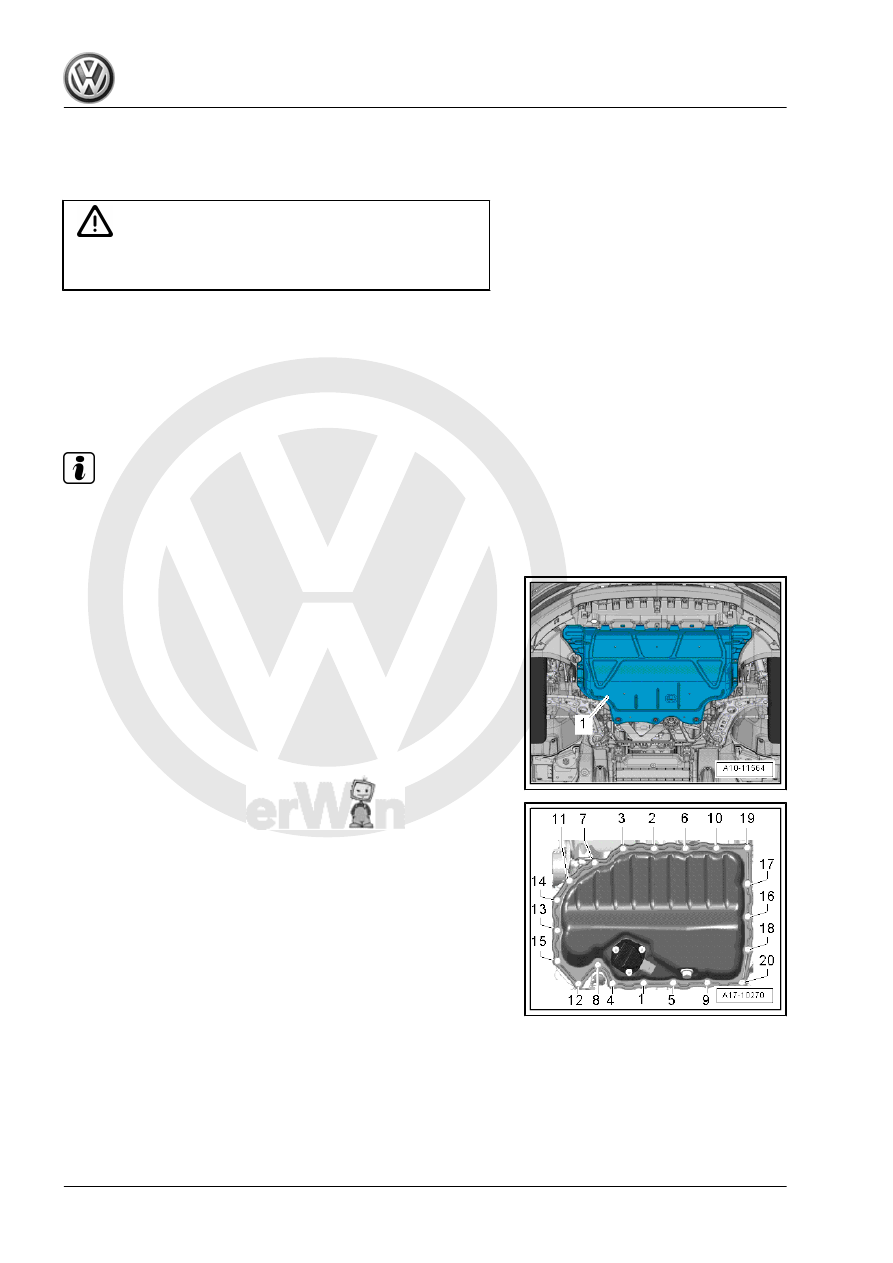

Removing

– Remove the noise insulation -1-. Refer to ⇒ Body Exterior;

Rep. Gr. 66 ; Noise Insulation; Overview - Noise Insulation .

– Place the Used Oil Collection and Extraction Unit -

SMN372500- under the engine and drain the engine oil.

– Remove the bolts -1 through 20- and remove the oil pan.