Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 654

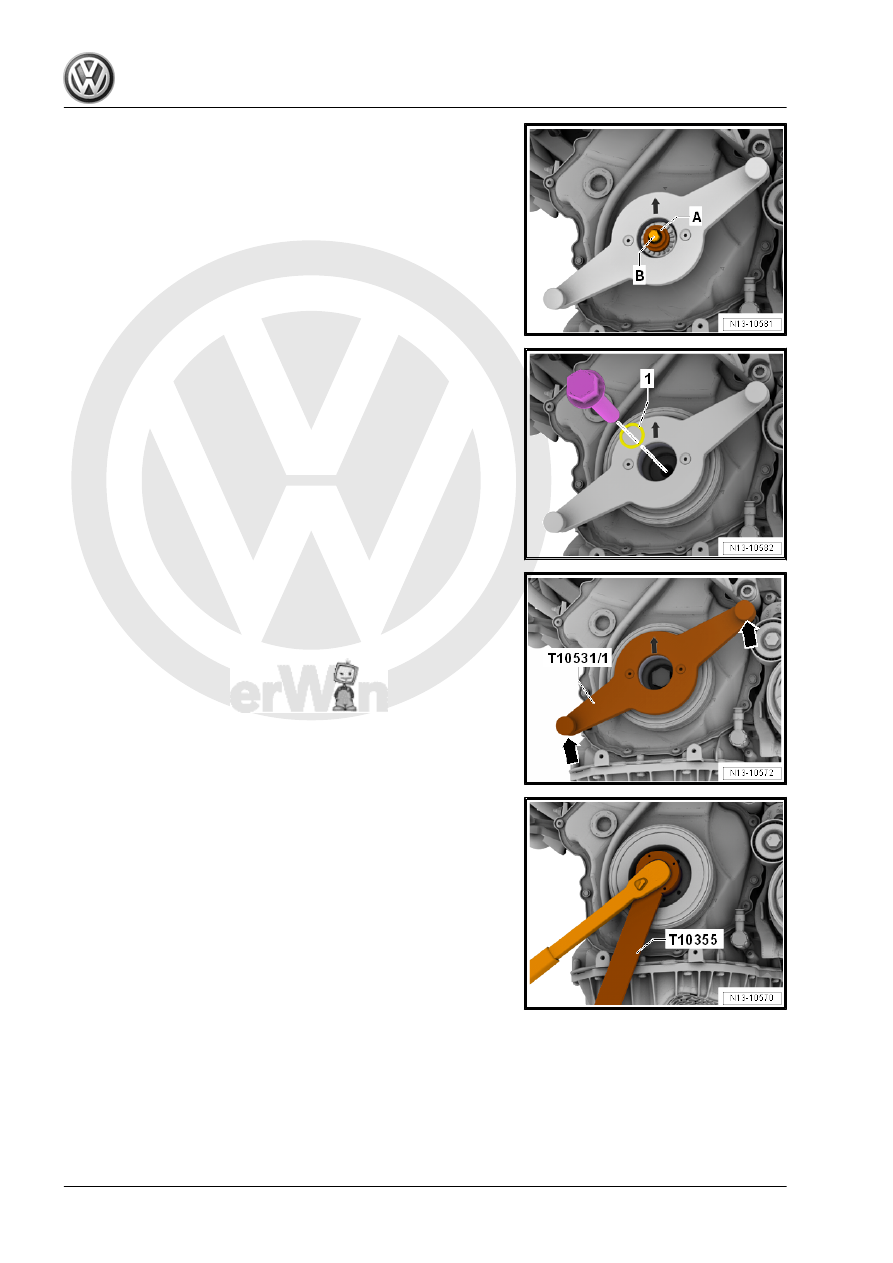

– Remove the Collar Nut -A- and loosen the tensioning bolt

-B-.

– Remove the Tensioning Pins and remove with Assembly Tool

- Turning Over Tool .

– Install a new vibration damper bolt with oiled O-ring -1- hand-

tight.

– Remove the knurled bolt -arrows- and remove the Counter‐

hold Tool - T10531/1- .

– Tighten vibration damper bolt using the Counterhold - Vibra‐

tion Damper - T10355- .

– Install new bolts -arrows-.