Volkswagen Golf / Golf GTI / Golf Variant. Manual - part 490

1.9

Bearing Bushing, Removing and Instal‐

ling

Removing

Disconnect the battery ground cable. Refer to ⇒ Electrical Equip‐

ment; Rep. Gr. 27 ; Battery; Battery, Disconnecting and Con‐

necting .

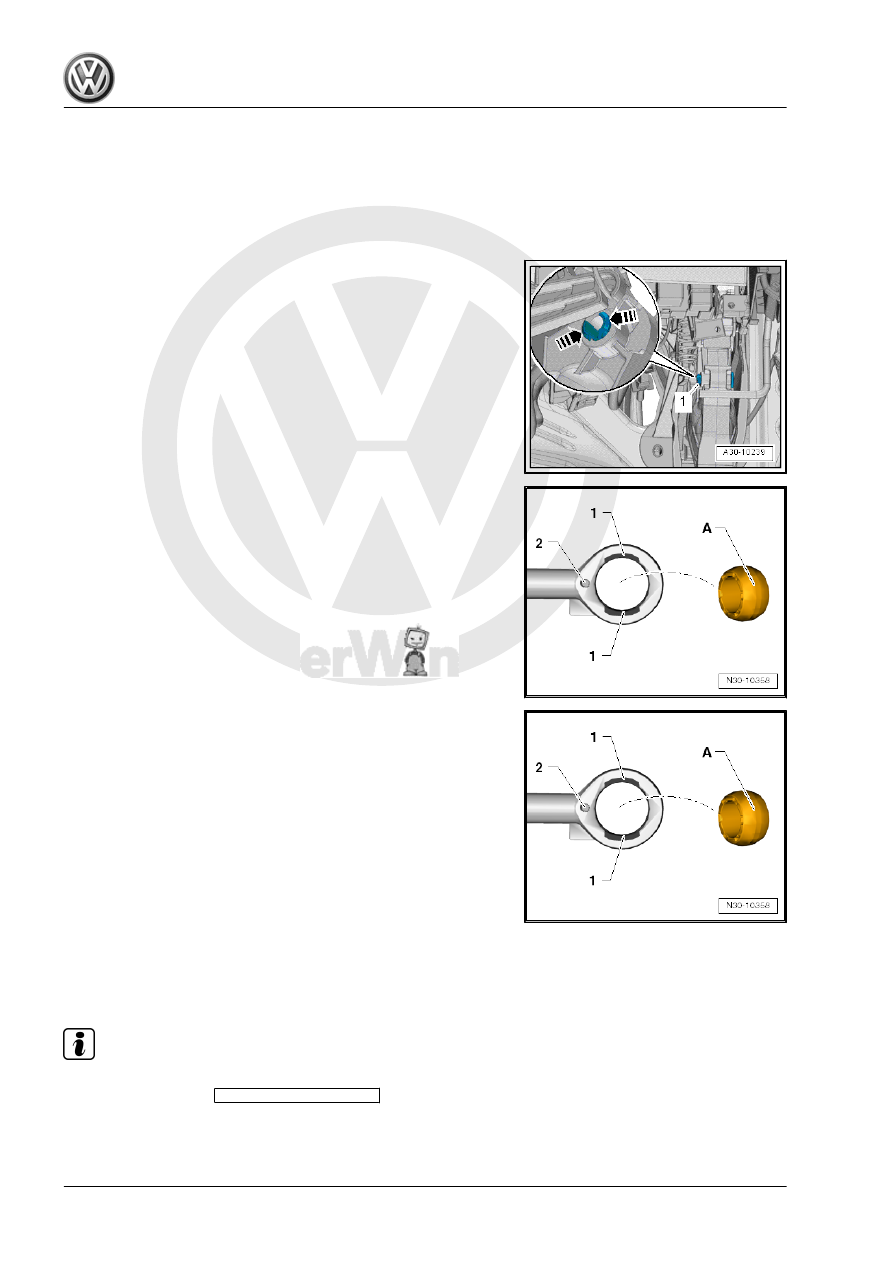

– Press together the retainers in the direction of -arrows- and

remove the studs -1- to the right side.

– Turn the valve fitter such that the openings -1- or pin -2- are

visible.

The openings -1- and the pin -2- face in the same direction.

– Remove the bearing bushing -A- from the openings -1-.

Installing

– Turn the valve fitter such that the openings -1- or pin -2- are

visible.

The openings -1- and the pin -2- face in the same direction.

– Fit the bearing bushing -A- in the openings -1- and rotate into

place.

– Use a new mounting pin to connect the valve fitter/clutch mas‐

ter cylinder to the clutch pedal.

– Connect the battery. Refer to ⇒ Electrical Equipment; Rep.

Gr. 27 ; Battery; Battery, Disconnecting and Connecting .

1.10

Clutch Master Cylinder, Removing and

Installing

Removing

Note

♦

Before replacing the clutch master cylinder due to an assumed

defect, perform the

Guided Fault Finding

Vehicle Diagno‐

sis Tester first.

♦

When working inside the footwell, cover the carpet with cloths

to protect it from leaking brake fluid.