Suzuki Grand Vitara JB627. Manual - part 276

7B-20 Air Conditioning System:

Visual Inspection

S6JB0B7204007

Visually check the following parts and systems.

A/C System Performance Inspection

S6JB0B7204008

1) Confirm that vehicle and environmental conditions

are as follows.

• Vehicle is put indoors.

• Ambient air temperature is within 15 – 35

°C (59 –

95

°F).

• Relative humidity is within 30 – 70%.

• There is no wind indoors.

• HVAC unit is normal condition.

• There is no air leakage from air ducts.

• Condenser fins are clean.

• Are filter is not clogged with dirt and dust.

• Battery voltage is 12 V or more.

• Radiator cooling fan operates normally.

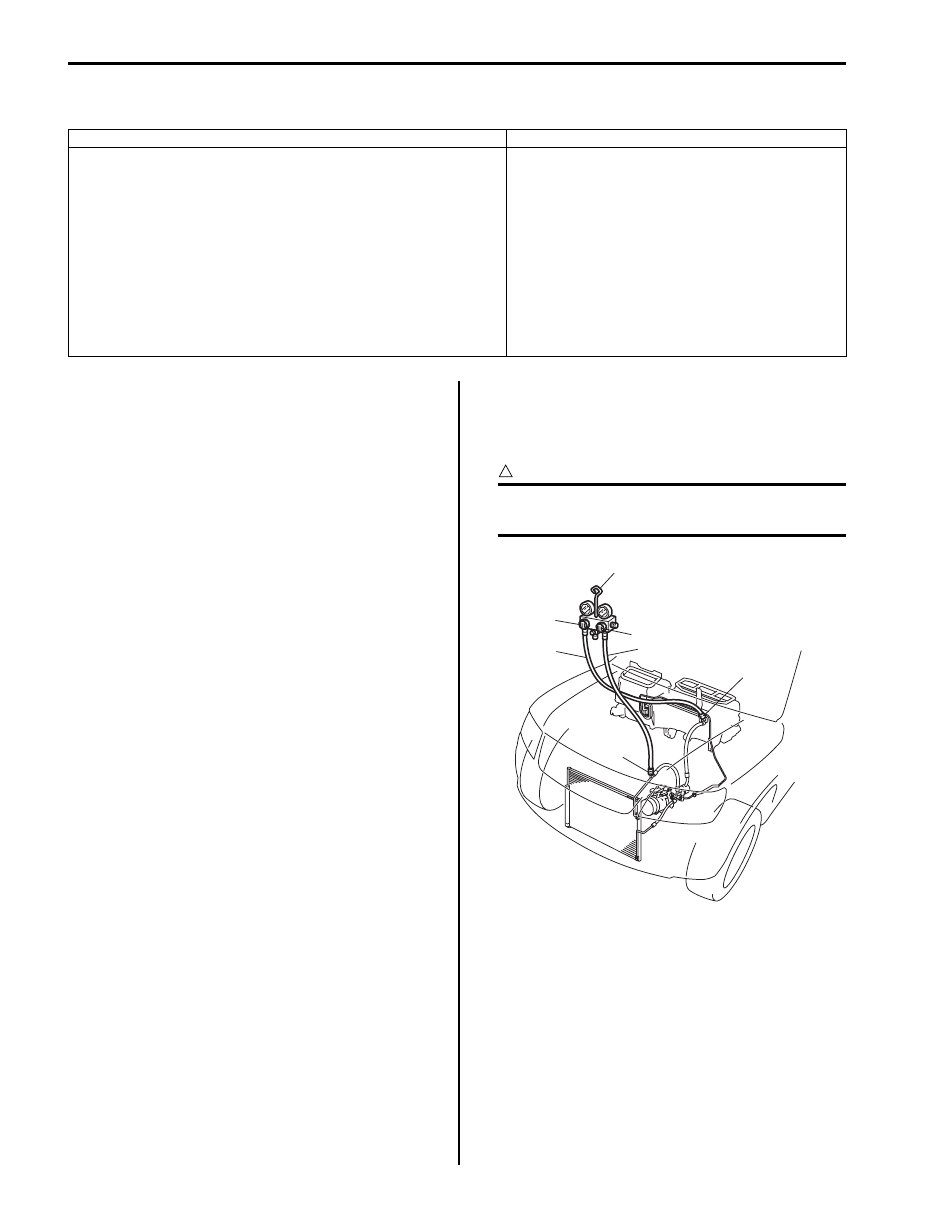

2) Make sure that high pressure valve (1) and low

pressure valve (2) of manifold gauge (3) are firmly

closed.

3) Connect high pressure charging hose (4) to high

pressure service valve (5) on vehicle, and connect

low pressure charging hose (6) to low pressure

service valve (7) on vehicle.

4) Bleed the air in charging hoses by loosening their

respective nuts on manifold gauge, utilizing the

refrigerant pressure. When a hiss is heard,

immediately tighten nut.

CAUTION

!

Do not interchange high and low pressure

charging hoses by mistake.

Inspection Item

Correction

• Refrigerant ---- leakage and amount

• A/C pipe or hose ---- disconnection, looseness and

deterioration

• A/C compressor drive belt ---- looseness and damage

• Battery ---- fluid level and corrosion of terminal

• Connectors of electric wire harness ---- disconnection and

friction

• Fuses ---- burning

• Parts ---- installation and damage

• Other parts that can be checked visually

Refer to “A/C Compressor Drive Belt Inspection

and Adjustment”.

3

7

4

1

2

6

5

I5JB0A720010-01