Subaru Legacy IV (2008 year). Manual - part 882

DI-77

Rear Differential (VA-type)

DIFFERENTIALS

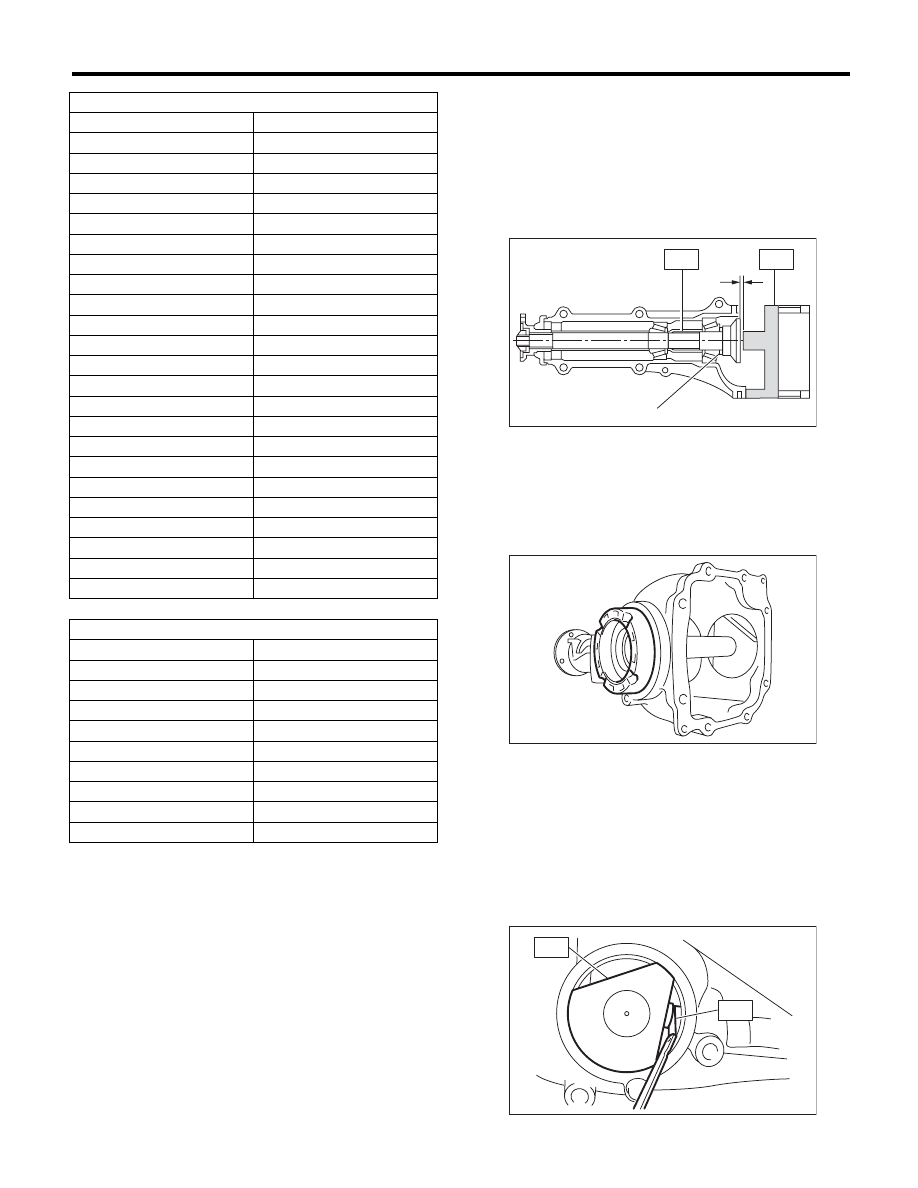

2) Adjusting drive pinion height:

Adjust the drive pinion height with washer installed

between the rear bearing cone and the back of pin-

ion gear.

(1) Attach ST2.

ST1

18678AA000 DUMMY SHAFT

ST2

18831AA010 DIFFERENTIAL CARRIER

GAUGE

(2) Install the side retainer LH to the left side of

the differential carrier in the reverse direction.

(3) Measure the clearance “N” between the end

of ST2 and the end surface of ST1 by using a

thickness gauge.

NOTE:

Make sure there is no clearance between the case

and ST2.

ST1

18678AA000 DUMMY SHAFT

ST2

18831AA010 DIFFERENTIAL CARRIER

GAUGE

Preload adjusting washer

Part No.

Thickness mm (in)

38336AA430

1.500 (0.0591)

38336AA440

1.513 (0.0596)

38336AA450

1.525 (0.0600)

38336AA460

1.538 (0.0606)

38336AA470

1.550 (0.0610)

38336AA480

1.563 (0.0615)

38336AA490

1.575 (0.0620)

38336AA500

1.588 (0.0625)

38336AA510

1.600 (0.0630)

38336AA520

1.613 (0.0635)

38336AA530

1.625 (0.0640)

38336AA540

1.638 (0.0645)

38336AA550

1.650 (0.0650)

38336AA560

1.663 (0.0655)

38336AA570

1.675 (0.0659)

38336AA580

1.688 (0.0665)

38336AA590

1.700 (0.0669)

38336AA600

1.713 (0.0674)

38336AA610

1.725 (0.0679)

38336AA620

1.738 (0.0684)

38336AA630

1.750 (0.0689)

38336AA640

1.763 (0.0694)

38336AA650

1.775 (0.0699)

Preload adjusting spacer

Part No.

Length mm (in)

31454AA250

51.05 (2.010)

31454AA260

51.25 (2.018)

31454AA270

51.35 (2.022)

31454AA280

51.45 (2.026)

31454AA290

51.55 (2.030)

31454AA300

51.65 (2.033)

31454AA310

51.75 (2.037)

31454AA320

51.85 (2.041)

31454AA330

52.05 (2.049)

N Measured value

(A) Pinion height adjusting washer

RH

LH

N

(A)

ST2

ST1

DI-00379

DI-00380

DI-00381

ST2

ST1