Subaru Legacy IV (2008 year). Manual - part 883

DI-81

Rear Differential (VA-type)

DIFFERENTIALS

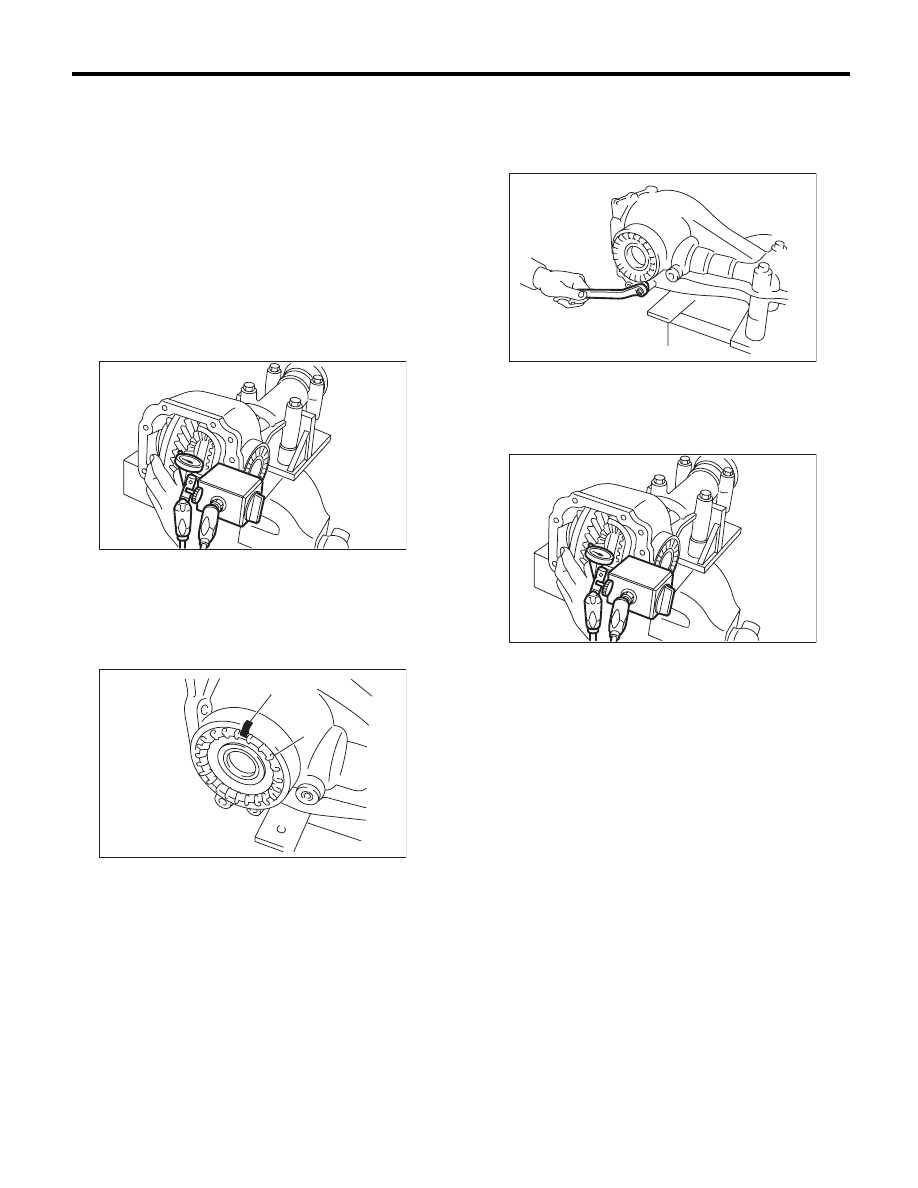

(5) Measure the hypoid driven gear-to-drive

pinion backlash. Set the magnet base on differ-

ential carrier. Align the contact point of dial

gauge with tooth face of hypoid driven gear,

and move hypoid driven gear while holding

drive pinion still. Read the value indicated on

dial gauge.

NOTE:

If measured value of backlash is not within the

specified range, repeat the procedures for pinion

driven gear set backlash adjustment and the differ-

ential side bearing preload adjustment.

Backlash:

0.10 — 0.15 mm (0.004 — 0.006 in)

16) Mark both the differential carrier and side re-

tainer with alignment marks. Remove the side re-

tainer one side at a time.

Replace them in the original position after inserting

an O-ring and applying differential gear oil to the

threaded portion.

17) Tighten the bolt of lock plate to specified

torque.

Tightening torque:

25 N·m (2.5 kgf-m, 18.4 ft-lb)

18) Recheck the hypoid driven gear to pinion back-

lash.

Backlash:

0.10 — 0.15 mm (0.004 — 0.006 in)

19) Checking and adjusting the tooth contact of hy-

poid driven gear

(1) Apply lead-free red dye evenly on the both

sides of three to four teeth of the hypoid driven

gear. Check the contact pattern after rotating

the hypoid driven gear several revolutions back

and forth until a definite contact pattern appears

on the hypoid driven gear.

(2) When the contact pattern is not correct, re-

adjust.

NOTE:

Be sure to wipe off the lead-free red dye completely

after the adjustment is completed.

(A) Alignment mark

(B) Side retainer

DI-00172

DI-00386

(B)

(A)

DI-00364

DI-00172