Subaru Legacy IV (2008 year). Manual - part 881

DI-73

Rear Differential (VA-type)

DIFFERENTIALS

17) Tighten the bolt of lock plate to specified

torque.

Tightening torque:

25 N·m (2.5 kgf-m, 18.4 ft-lb)

18) Recheck the hypoid driven gear to pinion back-

lash.

Backlash:

0.10 — 0.15 mm (0.004 — 0.006 in)

19) Checking and adjusting the tooth contact of hy-

poid driven gear

(1) Apply lead-free red dye evenly on the both

sides of three to four teeth of the hypoid driven

gear. Check the contact pattern after rotating

the hypoid driven gear several revolutions back

and forth until a definite contact pattern appears

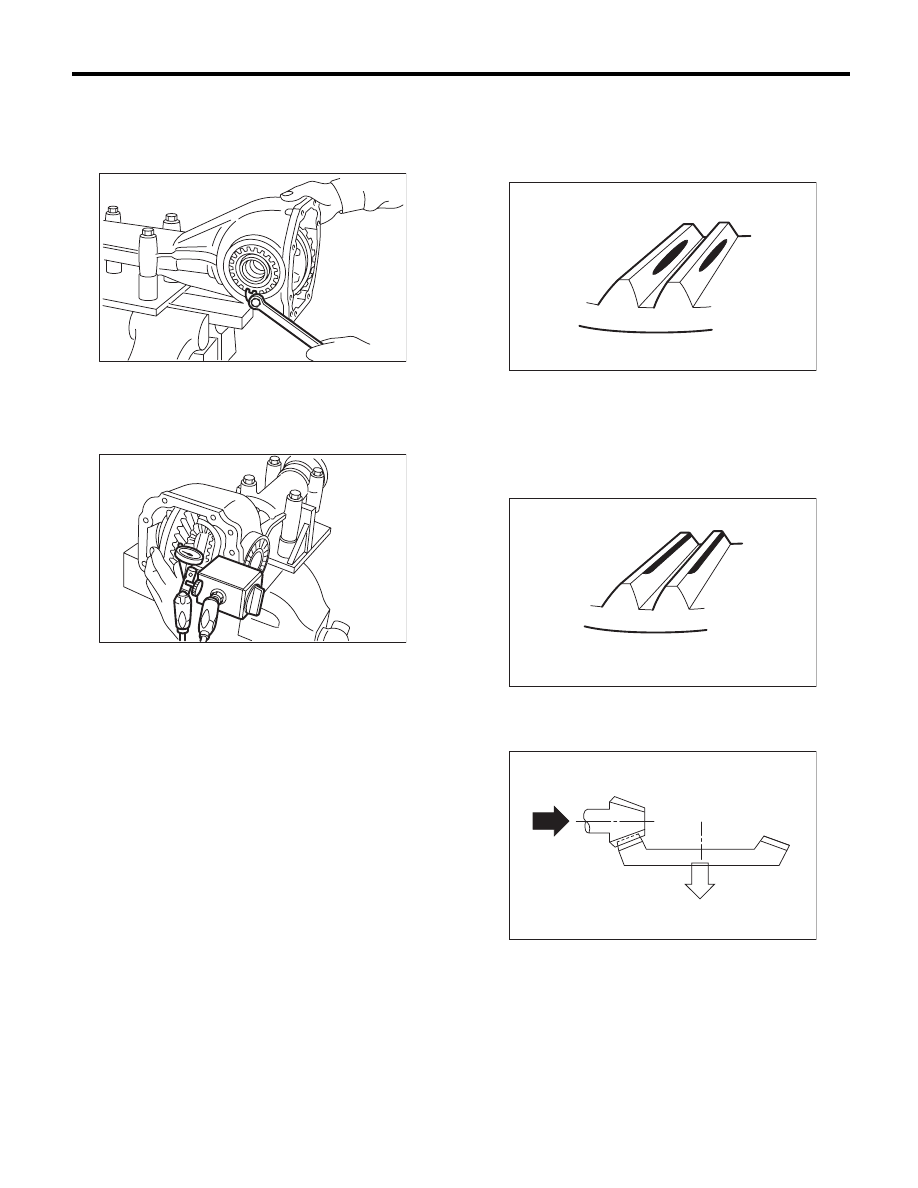

on the hypoid driven gear.

(2) When the contact pattern is not correct, re-

adjust.

NOTE:

Be sure to wipe off the lead-free red dye after the

adjustment is completed.

• Correct tooth contact

Check item: Tooth contact pattern is slightly

shifted towards the toe side under no-load

rotation. (When driving, it moves towards

the heel side.)

• Face contact

Check item: Backlash is too large.

Contact pattern

Corrective action: Increase thickness of drive

pinion height adjusting washer in order to bring

drive pinion close to hypoid driven gear.

DI-00132

DI-00172

(A) Toe side

(B) Heel side

(A)

(B)

MT-01401

AT-00208

AT-00212