Subaru Legacy IV (2008 year). Manual - part 879

DI-65

Rear Differential (VA-type)

DIFFERENTIALS

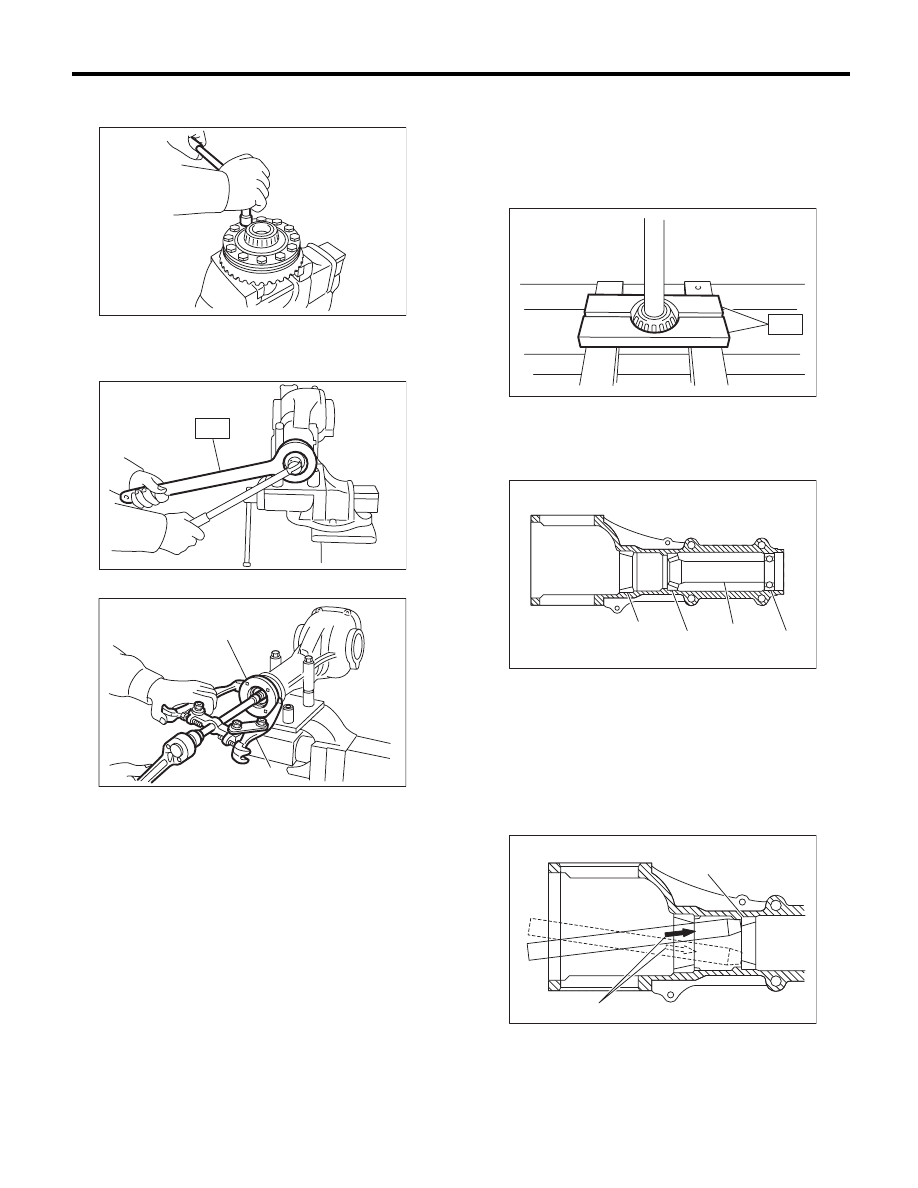

11) Remove the hypoid driven gear by loosening

hypoid driven gear bolts.

12) Remove the self-locking nut while holding the

companion flange with ST.

ST

498427200

FLANGE WRENCH

13) Extract the companion flange with a puller.

14) Removes the drive pinion shaft.

15) Remove the rear bearing cone from drive pin-

ion by supporting the cone with ST.

NOTE:

Place the replacer so that its center-recessed side

faces the pinion gear.

ST

398517700

REPLACER

16) Remove the front oil seal from differential carri-

er using screwdriver.

17) Remove the pilot bearing, front bearing cone

and spacer.

18) When replacing the bearings, hit out the front

bearing cup and rear bearing cup in this order using

a brass bar.

(A) Companion flange

(B) Puller

DI-00371

DI-00372

ST

(B)

(A)

DI-00394

(A) Pilot bearing

(B) Spacer

(C) Front bearing

(D) Rear bearing cup

(A) 2 cutout portions along diagonal lines

(B) Tap alternately with brass bar.

DI-00373

ST

(B)

(A)

(C)

(D)

DI-00374

(B)

(A)

DI-00077