Subaru Legacy IV (2008 year). Manual - part 880

DI-69

Rear Differential (VA-type)

DIFFERENTIALS

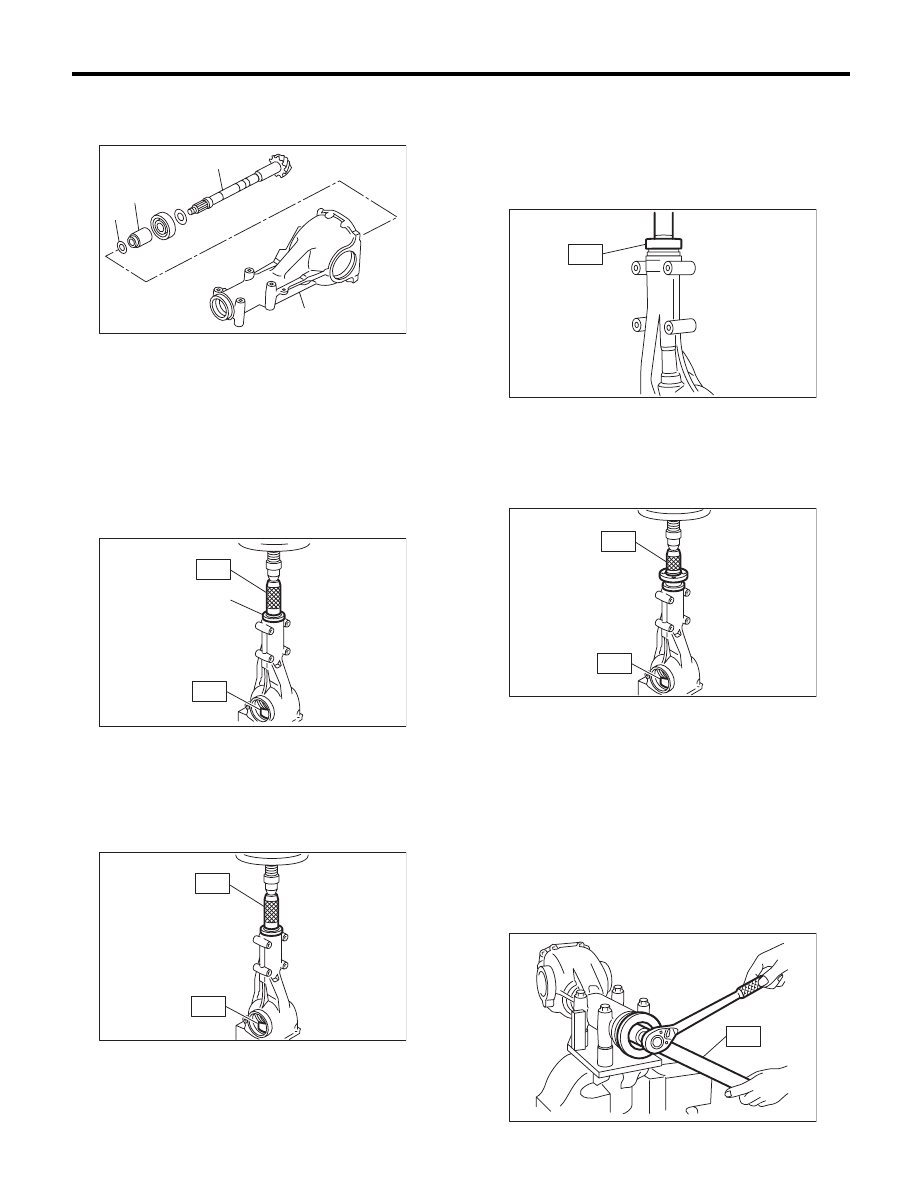

4) Insert the drive pinion into the differential carrier,

and install the preselected bearing preload adjust-

ing spacer and washer.

5) Press-fit the front bearing cone into the carrier

with ST1, ST2 and the spacer.

ST1

399780104

WEIGHT

ST2

899580100

INSTALLER

Part No.

32285AA000 Spacer

6) Insert the spacer, then press-fit the pilot bearing

with ST1 and ST2.

ST1

399780104

WEIGHT

ST2

899580100

INSTALLER

7) Fit a new oil seal with ST.

NOTE:

• Press-fit until the oil seal end comes 1 mm (0.04

in) inward from end of carrier.

• Apply the differential gear oil to the oil seal lips.

ST

498447120

INSTALLER

8) Press-fit the companion flange with ST1 and ST2.

NOTE:

Be careful not to damage the bearing.

ST1

899874100

INSTALLER

ST2

399780104

WEIGHT

9) Attach a new self-locking nut and secure the

companion flange using ST, then tighten the nut.

NOTE:

Before installing lock nuts, apply seal material to

lock nut threads.

SEAL MATERIAL:

THREE BOND 1324 (Part No. 004403042) or

equivalent

ST

498427200

FLANGE WRENCH

Tightening torque:

191 N·m (19.5 kgf-m, 140.9 ft-lb)

(A) Drive pinion

(B) Bearing preload adjusting spacer

(C) Bearing preload adjusting washer

(D) Differential carrier

(A) Spacer (SUBARU genuine part)

(D)

(A)

(B)

(C)

DI-00156

DI-00468

ST2

ST1

(A)

ST2

ST1

DI-00088

ST

DI-00089

ST1

ST2

DI-00090

ST

DI-00161