Opel Frontera UBS. Manual - part 541

7A–33

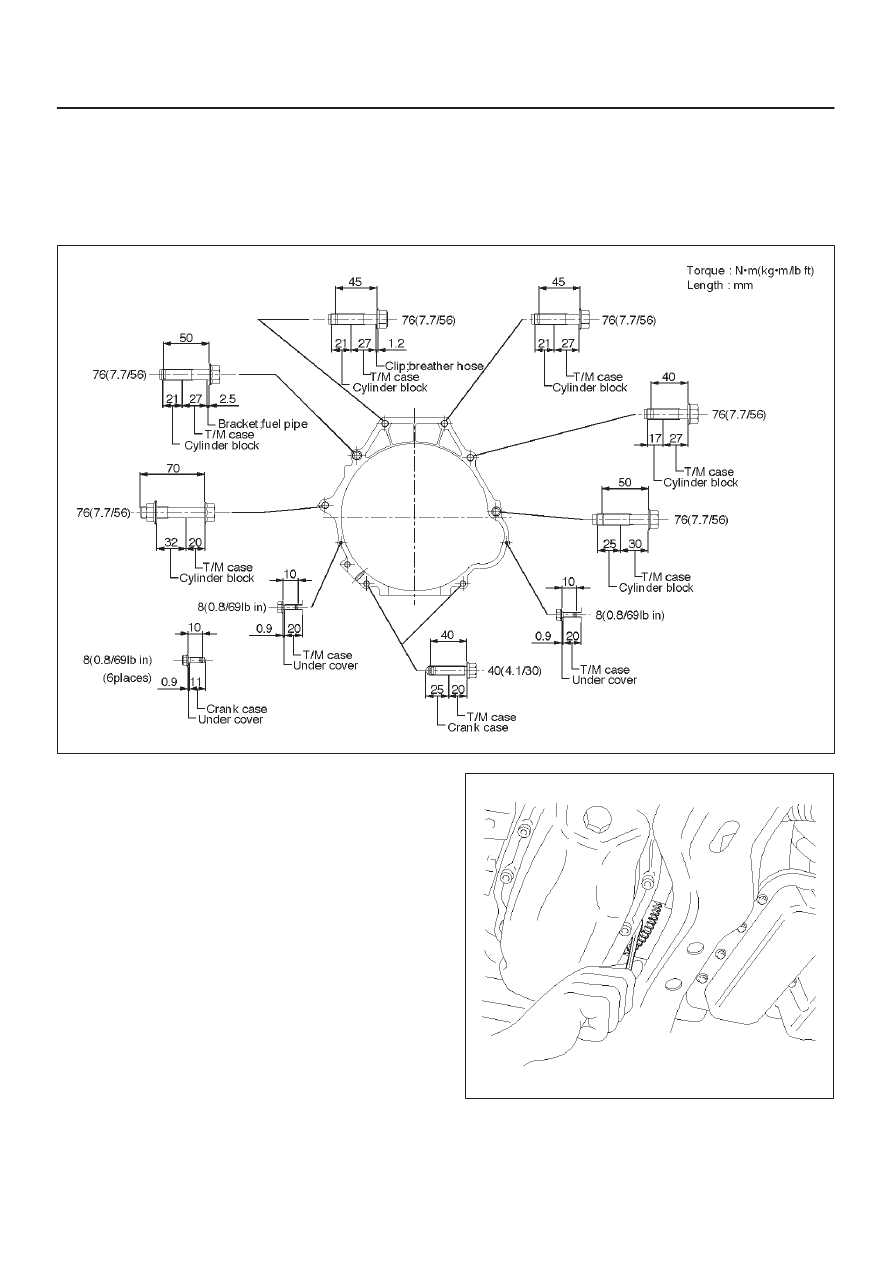

AUTOMATIC TRANSMISSION (4L30–E)

27. Remove transmission assembly (18).

Installation

1. Slowly raise transmission jack until front of the

transmission is aligned with rear of the engine, then

install transmission assembly.

2. Tighten engine transmission bolts to the specified

torque.

F07RW041

3. Support transfer case with a jack, and remove the

transmission jack.

4. Install flywheel torque converter bolts (6 pieces) by

turning crankshaft.

Torque: 54 N

•

m (5.5 kg·m/40 lb ft)

NOTE: Do not reuse the flywheel torque converter bolt.

240RW005