Opel Frontera UBS. Manual - part 539

7A–25

AUTOMATIC TRANSMISSION (4L30–E)

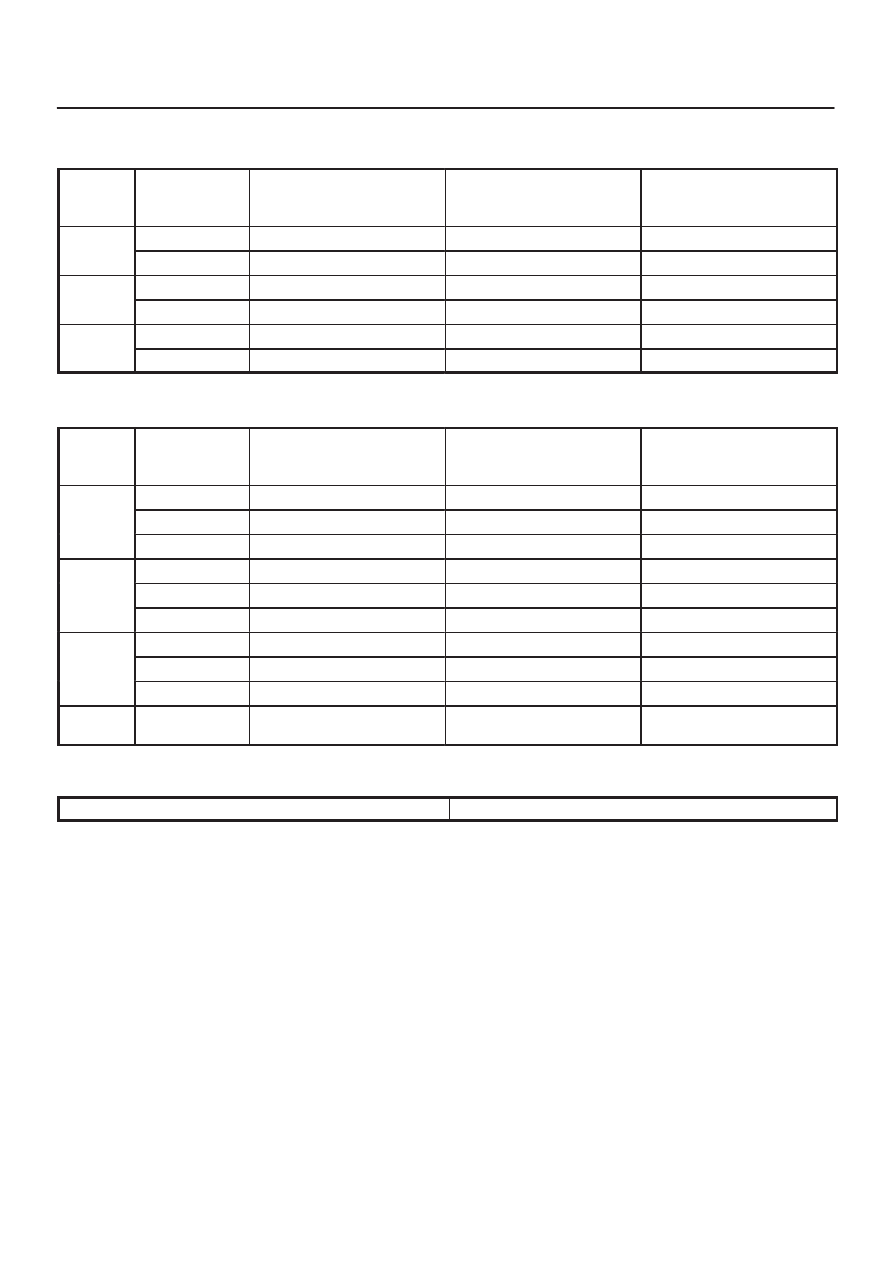

“Power mode”

Upshift

Range

Throttle

opening

1

→

2

(First Gear) (Second Gear)

Km/h (mph)

2

→

3

(Second Gear) (Third Gear)

Km/h (mph)

3

→

4

(Third Gear) (Fourth Gear)

Km/h (mph)

D

Fully opened

41

∼

47 (25

∼

29)

79

∼

85 (49

∼

53)

125

∼

131 (78

∼

81)

(Drive)

Half throttle

36

∼

42 (22

∼

26)

69

∼

75 (43

∼

47)

119

∼

125 (74

∼

78)

3

Fully opened

41

∼

47 (25

∼

29)

79

∼

85 (49

∼

53)

—

(Third)

Half throttle

36

∼

42 (22

∼

26)

69

∼

75 (43

∼

47)

—

2

Fully opened

41

∼

47 (25

∼

29)

—

—

(Second)

Half throttle

36

∼

42 (22

∼

26)

—

—

Downshift

Range

Throttle

opening

1

←

2

(First Gear) (Second Gear)

Km/h (mph)

2

←

3

(Second Gear) (Third Gear)

Km/h (mph)

3

←

4

(Third Gear) (Fourth Gear)

Km/h (mph)

D

Fully opened

28

∼

34 (17

∼

21)

70

∼

76 (43

∼

47)

115

∼

121 (71

∼

75)

D

(Drive)

Half throttle

20

∼

26 (12

∼

16)

46

∼

52 (29

∼

32)

90

∼

96 (56

∼

60)

(Drive)

Fully closed

12

∼

18 (7

∼

11)

22

∼

28 (14

∼

17)

43

∼

50 (27

∼

31)

3

Fully opened

28

∼

34 (17

∼

21)

70

∼

76 (43

∼

47)

—

3

(Third)

Half throttle

20

∼

26 (12

∼

16)

46

∼

52 (29

∼

32)

—

(Third)

Fully closed

12

∼

18 (7

∼

11)

22

∼

28 (14

∼

17)

—

2

Fully opened

28

∼

34 (17

∼

21)

82

∼

88 (51

∼

55)

—

2

(Second)

Half throttle

20

∼

26 (12

∼

16)

82

∼

88 (51

∼

55)

—

(Second)

Fully closed

12

∼

18 (7

∼

11)

82

∼

88 (51

∼

55)

—

L

(First)

—

36

∼

42 (22

∼

26)

—

—

“Winter mode”

D range, winter mode ON

→

OFF

27

∼

33 Km/h (17

∼

20 mph)