Opel Frontera UBS. Manual - part 264

6C–12

ENGINE FUEL

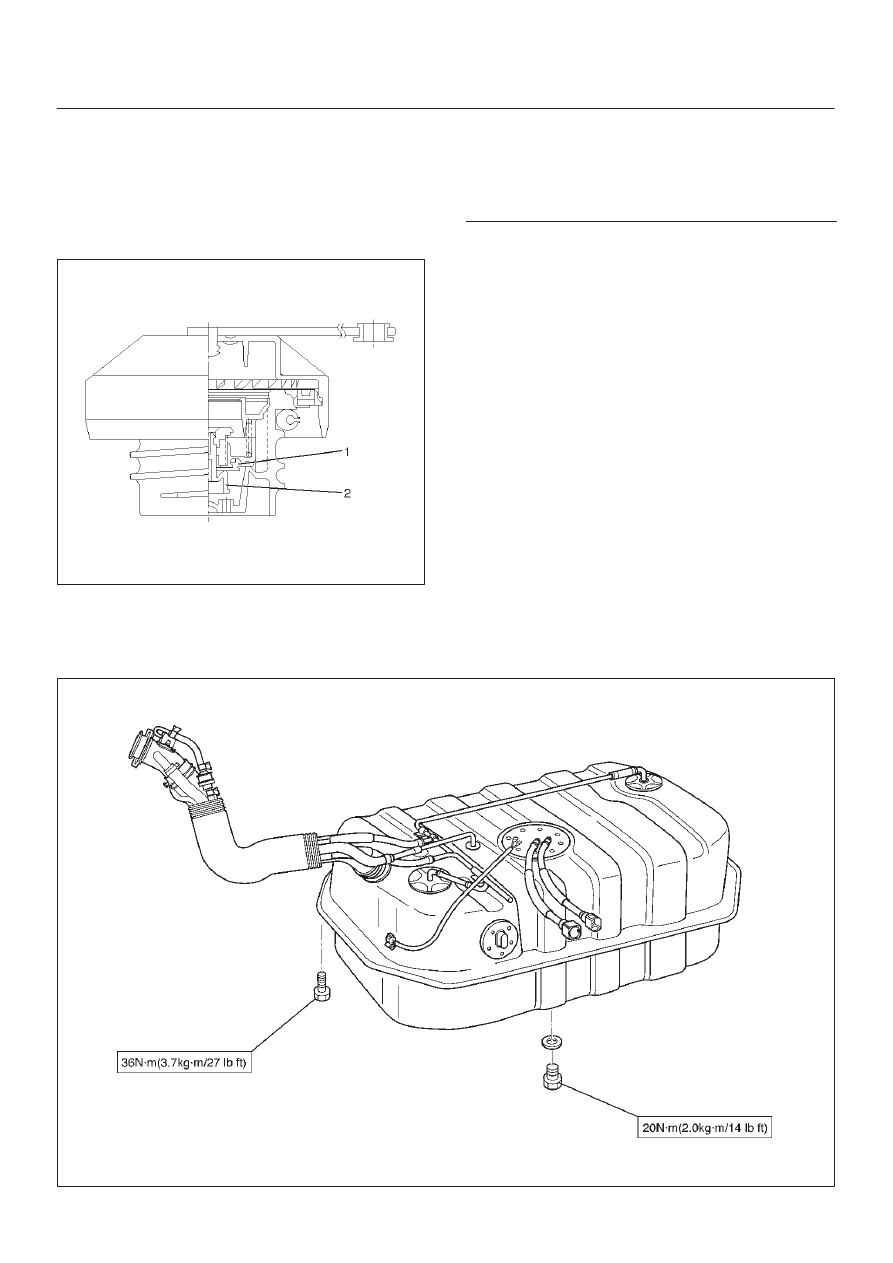

Fuel Filler Cap

General Description

Fuel filler cap includes vacuum valve and pressure valve.

In case any high vacuum and any high pressure happen in

tank, each valve works to adjust the pressure to prevent

the tank from being damaged.

140RW021

Legend

(1) Vacuum Valve

(2) Pressure Valve

Inspection

Check the seal ring in the filler cap for presence of any

abnormality and for seal condition.

Replace the filler cap, if abnormal.

CAUTION: The fuel filler cap valves have

characteristics.

A defective valve, no valve at all or a valve with the

wrong characteristics will do a lot of harm to engine

operating characteristics; be sure to use the same

fuel filler cap as installed in this vehicle.

Main Data and Specifications

Torque Specification

N·m (Kg·m/lb ft)

ȡ

035RW141