Opel Frontera UBS. Manual - part 263

6C–8

ENGINE FUEL

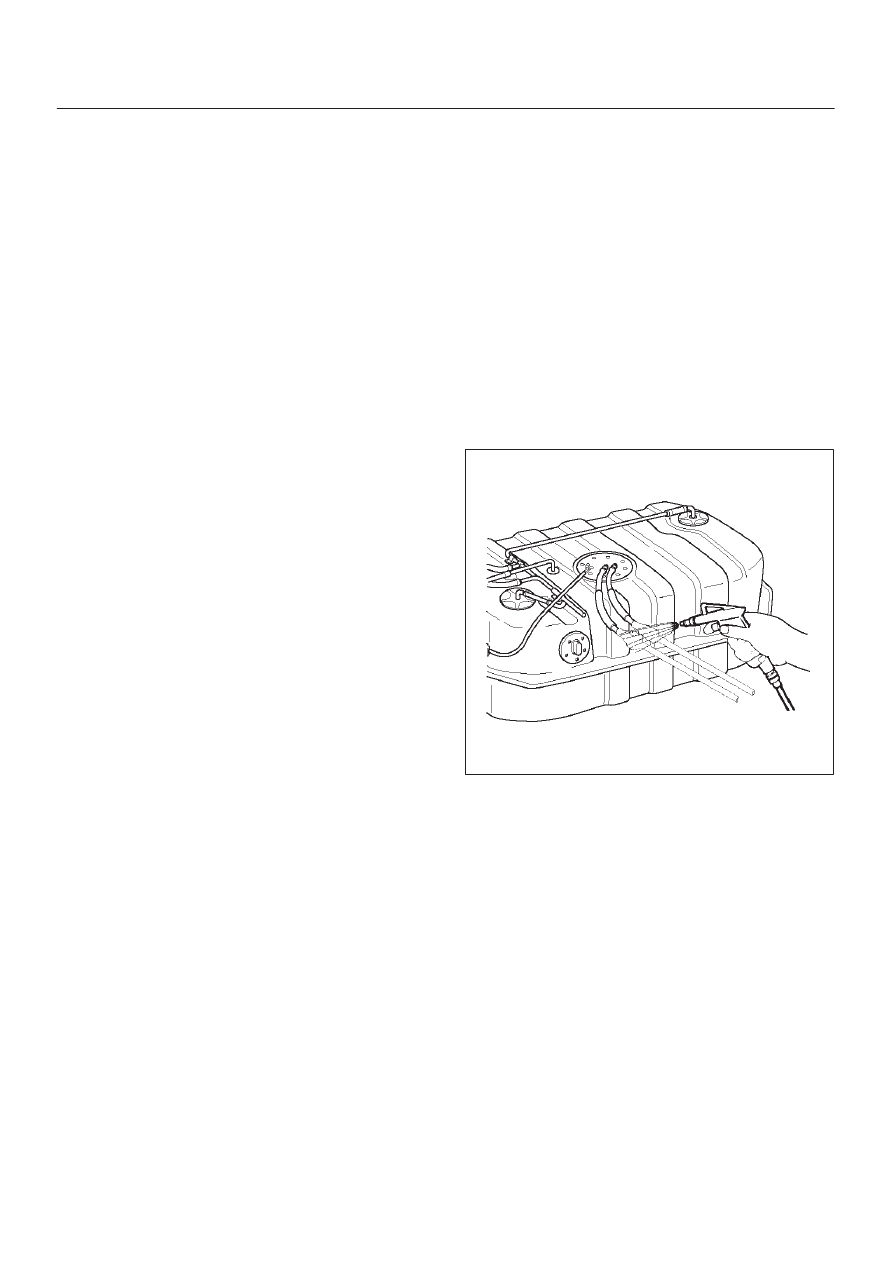

7. Disconnect two fuel tank wiring connectors(4) on

front right side of tank.

8. Disconnect evapo fuel hose(5).

9. Disconnect fuel feed tube and fuel return tube(6).

NOTE: Handling of the fuel tube, be sure to refer “Fuel

Tube/Quick–Connect Fittings” in this section.

10. Remove fuel tank fixing bolts on both sides and

remove fuel tank(7).

Installation

1. Install fuel tank(7).

D

Place a flange on right side of tank on the bracket.

D

Install a flange on left side on the bracket from the

bottom, and tighten bolts to the specified torque.

Torque: 36 N·m (3.7 Kg·m/27 lb ft)

2. Connect fuel feed tube and fuel return tube(6).

3. Connect evapo fuel hose(5).

4. Connect fuel tank wiring connector(4).

5. Install undercover(3).

6. Connect fuel filler hose, air breather hose and evapo

hose(2).

7. Install fender liner(1).

D

Mount fender liner to the wheel well.

D

Fill the tank with fuel and tighten fuel filler cap.

D

Connect battery ground cable.

Fuel Tube / Quick – Connect Fittings

Precautions

D

Lighting of Fires Prohibited.

D

Keep flames away from your work area to prevent the

inflammable from catching fire.

D

Disconnect the battery negative cable to prevent

shorting during work.

D

When welding or conducting other heat-generating

work on other parts, be sure to provide pretreatment

to protect the piping system from thermal damage or

spattering.

Cautions During Work

Do not expose the assembly to battery electrolyte or do

not wipe the assembly with a cloth used to wipe off spilt

battery electorolyte.

The piping wet with battery electrolyte cannot be used.

Be careful not to give a bending or twisting force to the

piping during the work. If deformed, replace with a new

piping.

Removal

1. Open the fuel cap to relieve the fuel pressure in the

tank.

If the fuel quick-connect fittings are dusty, clean with

an air blower, etc. and then remove it.

141RW016

As some pressure may remain in the piping, cover the

connector with a cloth, etc. to prevent the splashing

of fuel in the first disconnection of the piping.