Nissan Titan. Manual - part 629

OIL PAN

TM-199

< REMOVAL AND INSTALLATION >

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

OIL PAN

Removal and Installation

INFOID:0000000009885918

REMOVAL

1. Drain A/T fluid. Refer to

TM-174, "Changing the A/T Fluid (ATF)"

.

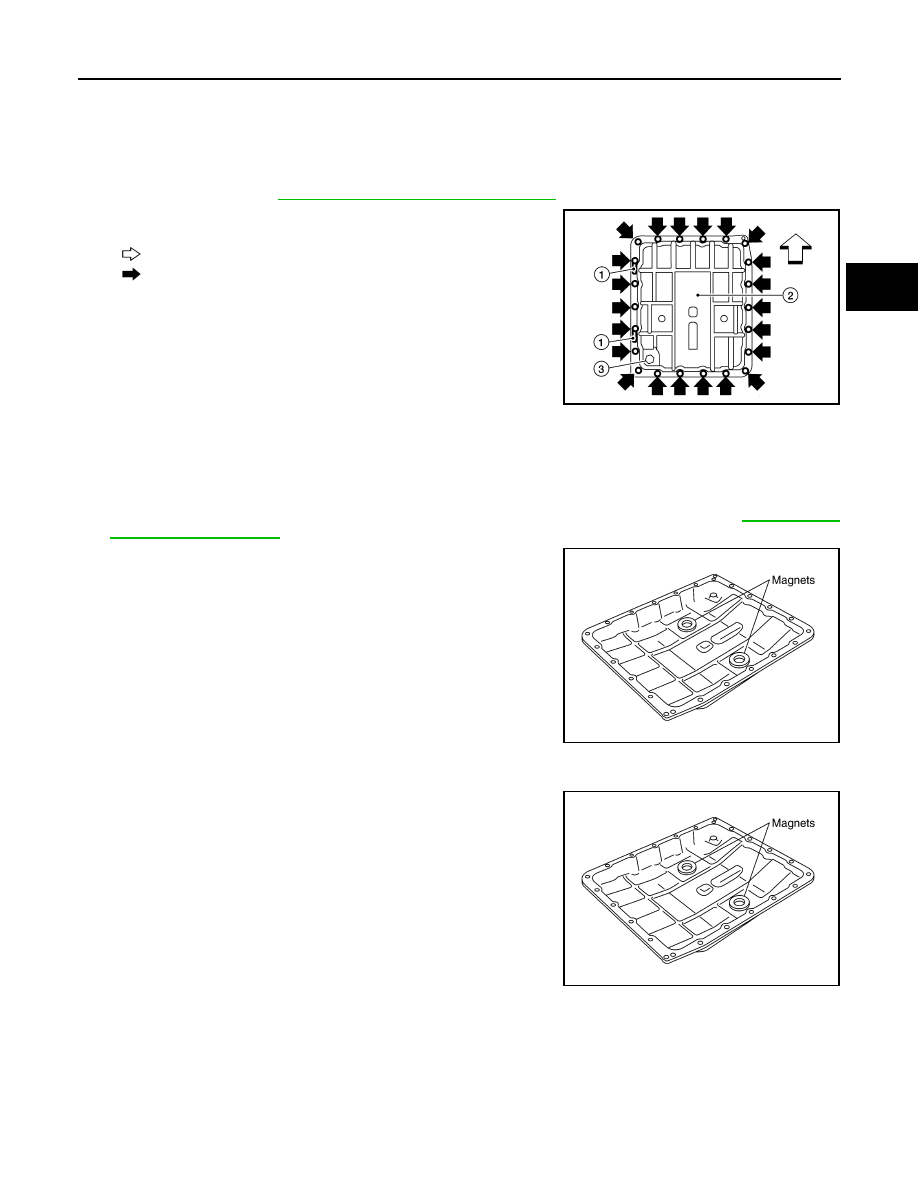

2. Remove oil pan (2).

a. Remove oil pan clips (1).

•

: Front

•

: Oil pan bolts

• Drain plug (3)

3. Remove oil pan gasket.

4. Check for foreign materials in oil pan to help determine cause of malfunction. If the A/T fluid is very dark,

has some burned smell, or contains foreign particles then friction material (clutches, band) may need

replacement. A tacky film that will not wipe clean indicates varnish build up. Varnish can cause valves,

servo, and clutches to stick and can inhibit pump pressure.

CAUTION:

If friction material is detected, flush the transmission cooler after repair. Refer to

5. Remove magnets from oil pan.

INSTALLATION

1. Install the oil pan magnets as shown.

AWDIA0023ZZ

SCIA5200E

SCIA5200E