Nissan Titan. Manual - part 304

EM-20

< PERIODIC MAINTENANCE >

CAMSHAFT VALVE CLEARANCE

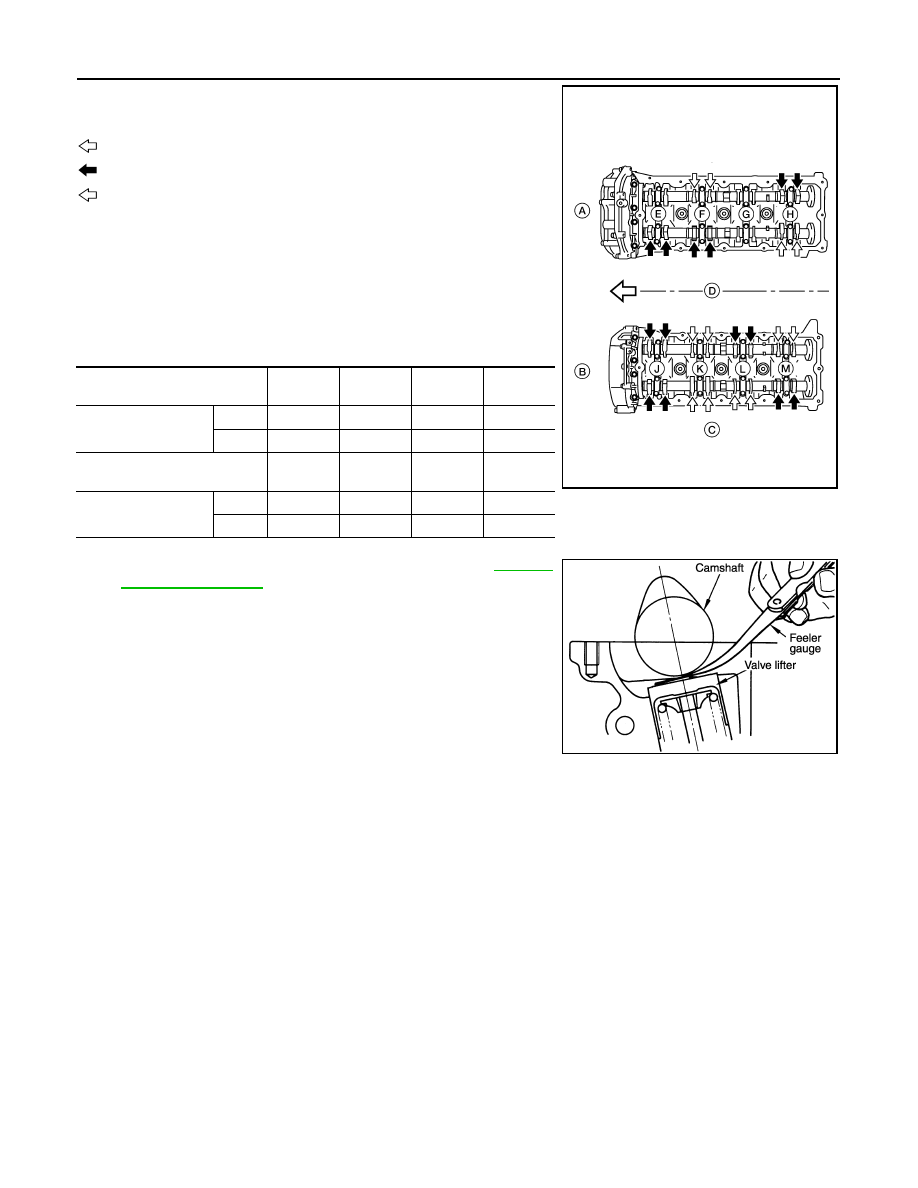

6. Measure valve clearances at the locations marked “

×” as shown

in the table below (locations indicated with black arrow).

NOTE:

Firing order 1-8-7-3-6-5-4-2

• No. 1 cylinder compression TDC

• Measure valve clearance using suitable tool. Refer to

CAUTION:

If the inspection was carried out with a cold engine, make

sure the values with a fully warmed up engine are still

within specifications.

7. Turn the crankshaft pulley clockwise 270

° from the position of No. 1 cylinder compression TDC to obtain

No. 3 cylinder compression TDC.

: Engine front

: Measurable at No.1 cylinder compression top dead center (black)

: Measurable at No. 3 cylinder compression top dead center (white)

(A)

: (RH)

(B)

: (LH)

(C)

: Exhaust

(D)

: Intake

Measuring position (RH bank)

No. 2 cyl

(E)

No. 4 cyl

(F)

No. 6 cyl

(G)

No. 8 cyl

(H)

No. 1 cylinder at TDC

EXH

×

INT

×

×

Measuring position (LH bank)

No. 1 cyl

(J)

No. 3 cyl

(K)

No. 5 cyl

(L)

No. 7 cyl

(M)

No. 1 cylinder at TDC

INT

×

×

EXH

×

×

WBIA0713E

KBIA0185E