Nissan Titan. Manual - part 305

EM-24

< PERIODIC MAINTENANCE >

COMPRESSION PRESSURE

COMPRESSION PRESSURE

Checking Compression Pressure

INFOID:0000000009886407

1. Warm up the engine thoroughly. Then stop the engine.

2. Release the fuel pressure. Refer to

CAUTION:

If CONSULT is not used to release fuel pressure leave the fuel pump fuse disconnected until step

7.

3. Remove the spark plug from each cylinder. Refer to

EM-17, "Removal and Installation"

4. Connect the engine tachometer (not required in use of CONSULT).

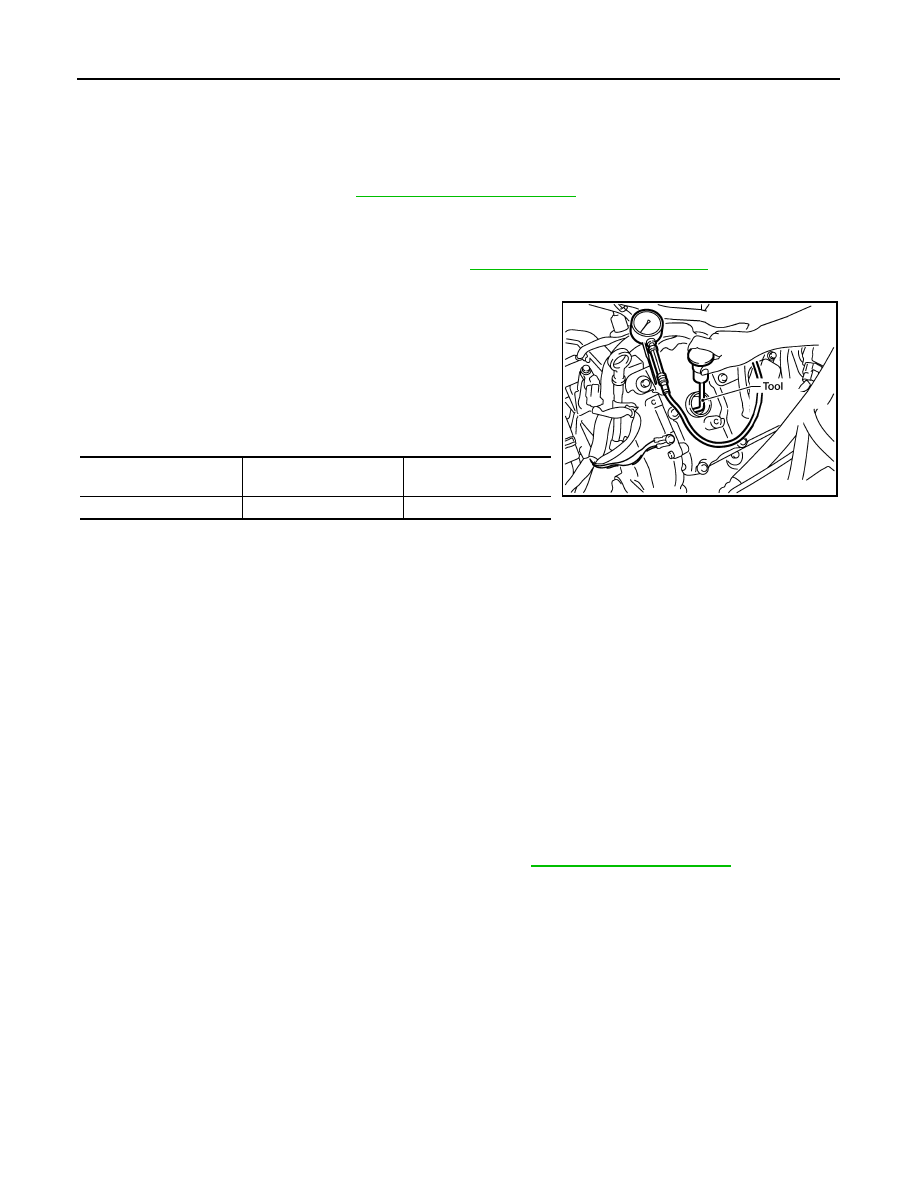

5. Install the compression tester with Tool into the spark plug hole.

6. With the accelerator pedal fully depressed, turn the ignition

switch to “START” for cranking. When the gauge pointer stabi-

lizes, read the compression pressure and engine rpm. Perform

these steps to check each cylinder.

Unit: kPa (kg/cm

2

, psi) /rpm

CAUTION:

Always use a fully charged battery to obtain specified engine speed.

• If the engine speed is out of the specified range, check the battery liquid for proper gravity. Check the

engine speed again with normal battery gravity.

• If the compression pressure is below the minimum value, check the valve clearances and parts associ-

ated with the combustion chamber (valve, valve seat, piston, piston ring, cylinder bore, cylinder head,

cylinder head gasket). After checking, measure the compression pressure again.

• If some cylinders have low compression pressure, pour a small amount of engine oil into the spark plug

hole of the cylinder to re-check it for compression.

- If the added engine oil improves the compression, the piston rings may be worn out or damaged. Check

the piston rings and replace if necessary.

- If the compression pressure remains at a low level despite the addition of engine oil, the valves may be

malfunctioning. Check the valves for damage. Replace the valve or valve seat accordingly.

• If two adjacent cylinders have respectively low compression pressure and their compression remains

low even after the addition of engine oil, the gaskets may be leaking, or a valve in adjacent cylinders

may be damaged. Inspect and repair as required.

7. Installation of the components is in the reverse order of removal.

8. Start the engine and confirm that it runs smoothly.

9. Perform trouble diagnosis. If DTC appears, erase it. Refer to

Tool number

: EG15050500 (J-45402)

Standard

Minimum

Deference limit be-

tween cylinders

1,520 (15.5, 220) / 200

1,324 (13.5, 192) / 200

98 (1.0, 14) / 200

WBIA0605E