Nissan Titan A60. Manual - part 539

FL-12

< UNIT REMOVAL AND INSTALLATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

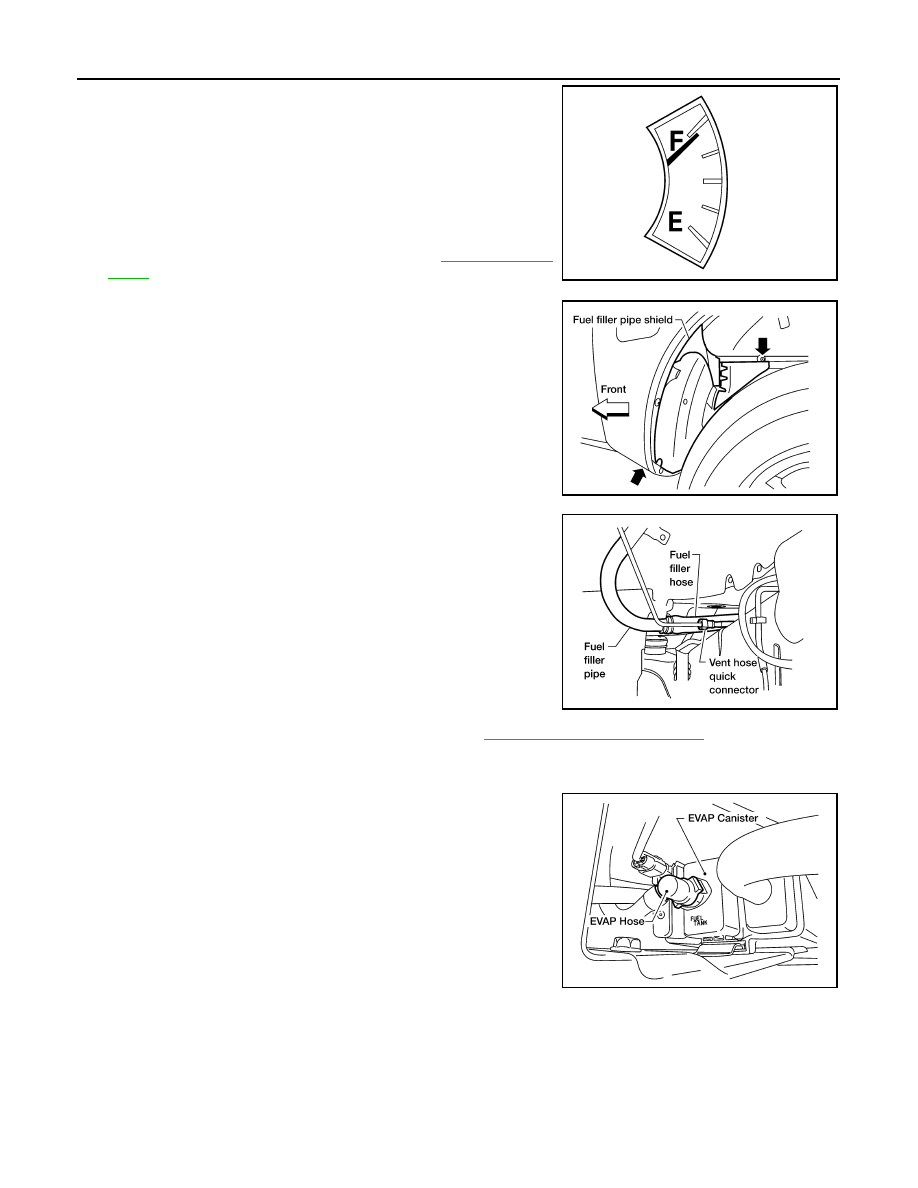

2. Check the fuel level on level gauge. If the fuel gauge indicates

more than the level as shown (full or almost full), drain the fuel

from the fuel tank until the fuel gauge indicates the level as

shown, or less.

• If the fuel pump does not operate, use the following procedure

to drain the fuel to the specified level.

a. Insert a suitable hose of less than 15 mm (0.59 in) diameter into

the fuel filler pipe through the fuel filler opening to drain the fuel

from fuel filler pipe.

b. Remove the LH rear wheel and tire. Refer to

c.

Remove the fuel filler pipe shield.

d. Disconnect the fuel filler hose from the fuel filler pipe and dis-

connect the vent hose quick connector.

e. Insert a suitable hose into the fuel tank through the fuel filler

hose to drain the fuel from the fuel tank.

3. Release the fuel pressure from the fuel lines. Refer to

4. Disconnect the battery negative terminal.

5. Remove the three nuts and remove fuel line pump protector.

6. Disconnect the EVAP hose at the EVAP canister.

WBIA0390E

LBIA0437E

LBIA0386E

LBIA0405E