Nissan Titan A60. Manual - part 464

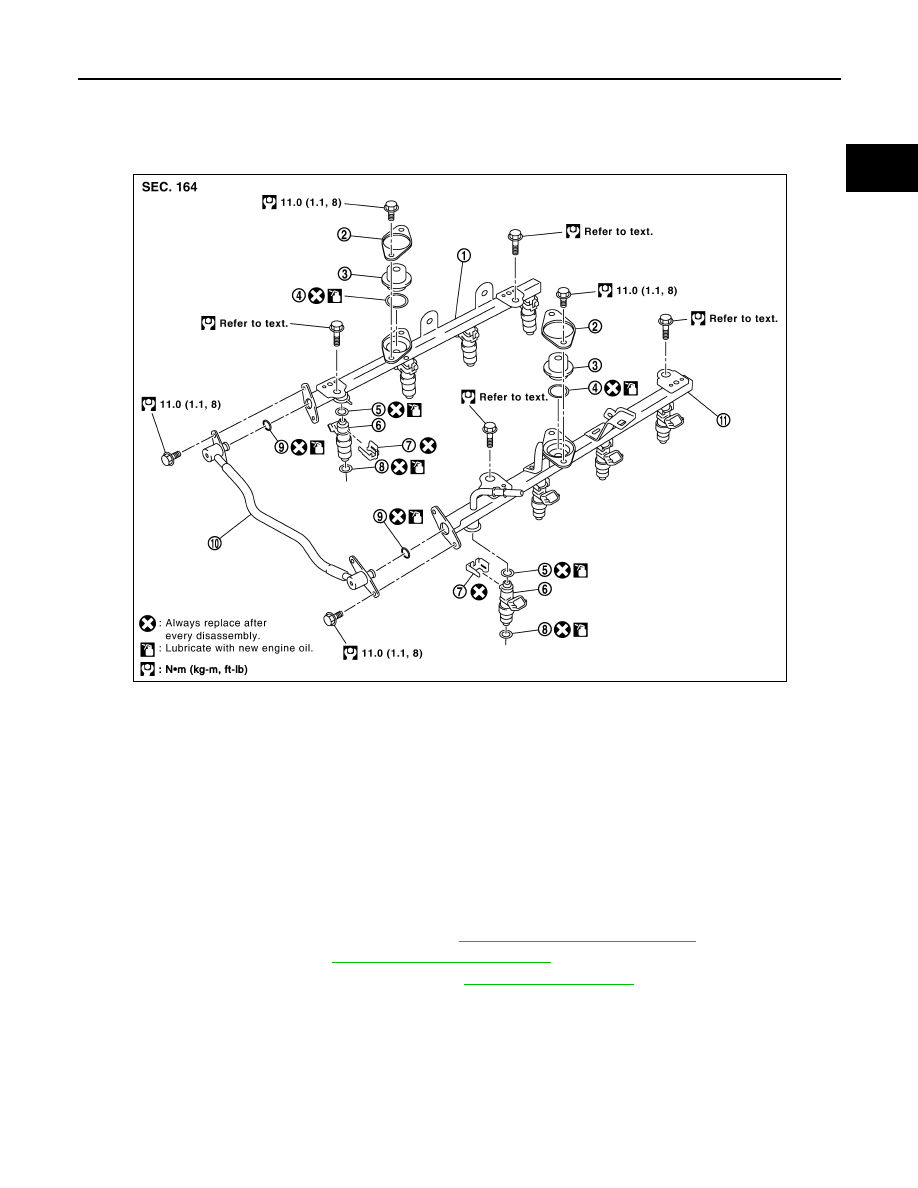

FUEL INJECTOR AND FUEL TUBE

EM-41

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

FUEL INJECTOR AND FUEL TUBE

Exploded View

INFOID:0000000006179401

Removal and Installation

INFOID:0000000006179402

CAUTION:

Do not remove or disassemble parts unless instructed as shown.

REMOVAL

1. Disconnect the negative battery terminal. Refer to

PG-76, "Removal and Installation"

2. Release fuel pressure. Refer to

.

3. Remove air duct and resonator assembly. Refer to

4. Disconnect fuel injector harness connectors.

5. Disconnect EVAP canister purge control solenoid valve.

6. Disconnect fuel hose assembly from fuel tube (RH bank and LH bank).

CAUTION:

• While hoses are disconnected, plug them to prevent fuel from draining.

• Do not separate fuel connector and fuel hose.

7. Remove fuel injectors with fuel tube assembly.

1.

Fuel tube (RH bank)

2.

Cap

3.

Fuel damper

4.

O-ring

5.

O-ring (Standard model: Blue)

(FFV model: Black)

6.

Fuel injector

7.

Clip

8.

O-ring (Standard model: Brown)

(FFV model: Green)

9.

O-ring

10. Fuel hose assembly

11. Fuel tube (LH bank)

KBIA2472E