Nissan Titan A60. Manual - part 174

BRC-74

< DTC/CIRCUIT DIAGNOSIS >

[VDC/TCS/ABS]

C1179 ABS DELTA S SEN NG

C1179 ABS DELTA S SEN NG

Description

INFOID:0000000006165917

The active brake booster consists of a vacuum booster, an active booster control group and a delta stroke

sensor. If a brake booster system malfunction occurs due to loss of vacuum, the delta stroke sensor will signal

the ABS actuator and electric unit (control unit) that a booster malfunction has occurred. The active booster

then applies supplemental force to the master cylinder relative to the amount of force exerted on the brake

pedal.

DTC Logic

INFOID:0000000006165918

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

CHECK SELF-DIAGNOSIS RESULTS

Check the self-diagnosis results.

Is above displayed on the self-diagnosis display?

YES

>> Proceed to diagnosis procedure. Refer to

.

NO

>> Inspection End

Diagnosis Procedure

INFOID:0000000006165919

Regarding Wiring Diagram information, refer to

1.

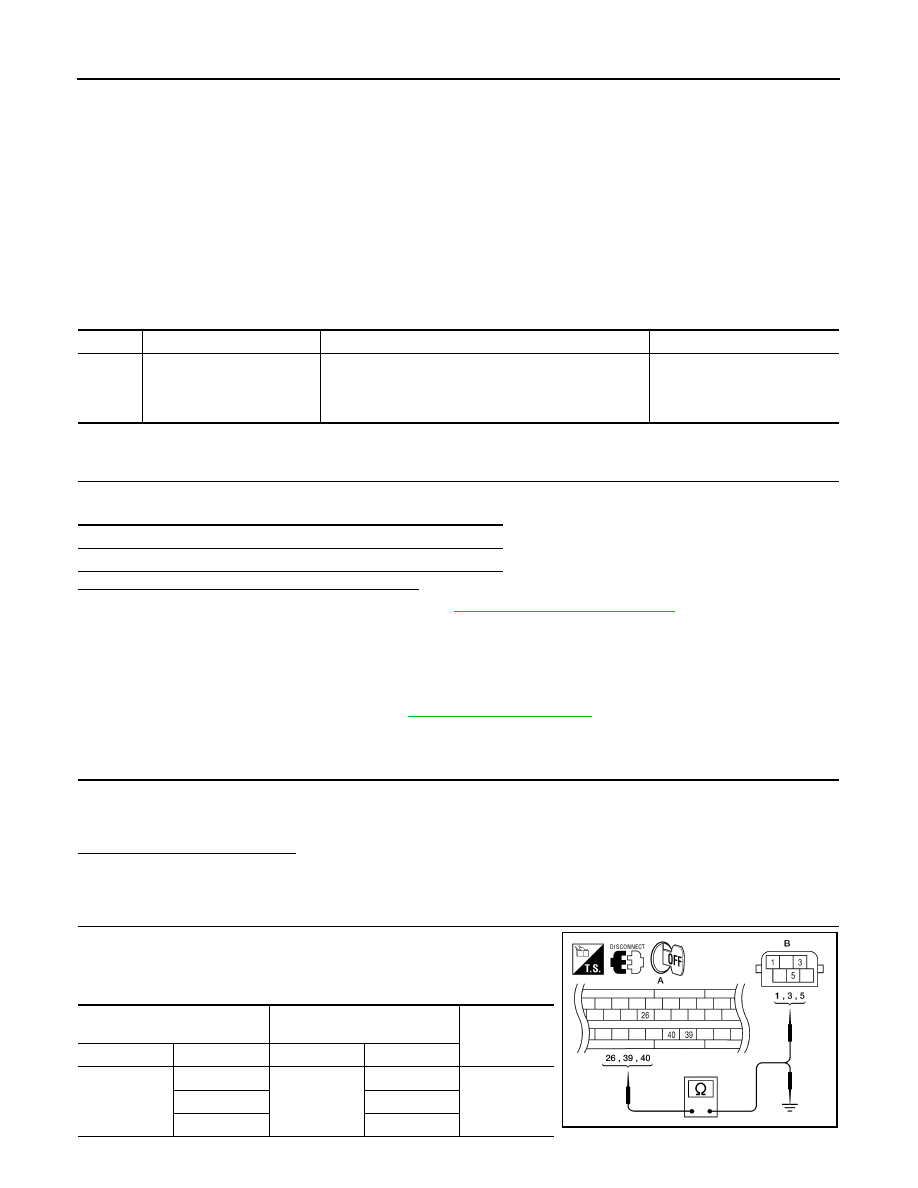

CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Disconnect the delta stroke sensor and ABS actuator and electric unit (control unit) connectors.

3. Inspect the terminals for deformation, disconnection, looseness, or damage.

Is the inspection result normal?

YES

>> GO TO 2

NO

>> Repair connector.

2.

DELTA STROKE SENSOR CIRCUIT INSPECTION

1. Measure the continuity between ABS actuator and electric unit

(control unit) connector E125 (A) and delta stroke sensor con-

nector E114 (B).

DTC

Display item

Malfunction detected condition

Possible cause

C1179

ABS DELTA S SEN NG

Delta stroke sensor is malfunctioning, or signal line of

delta stroke sensor is open or shorted.

• Harness or connector

• Delta stroke sensor

• ABS actuator and electric unit

(control unit)

Self-diagnosis results

ABS DELTA S SEN NG

ABS actuator and electric unit

(control unit)

Delta stroke sensor

Continuity

Connector

Terminal

Connector

Terminal

A: E125

26

B: E114

1

Yes

39

3

40

5

AWFIA0029ZZ