Nissan Cube. Manual - part 664

MA-30

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

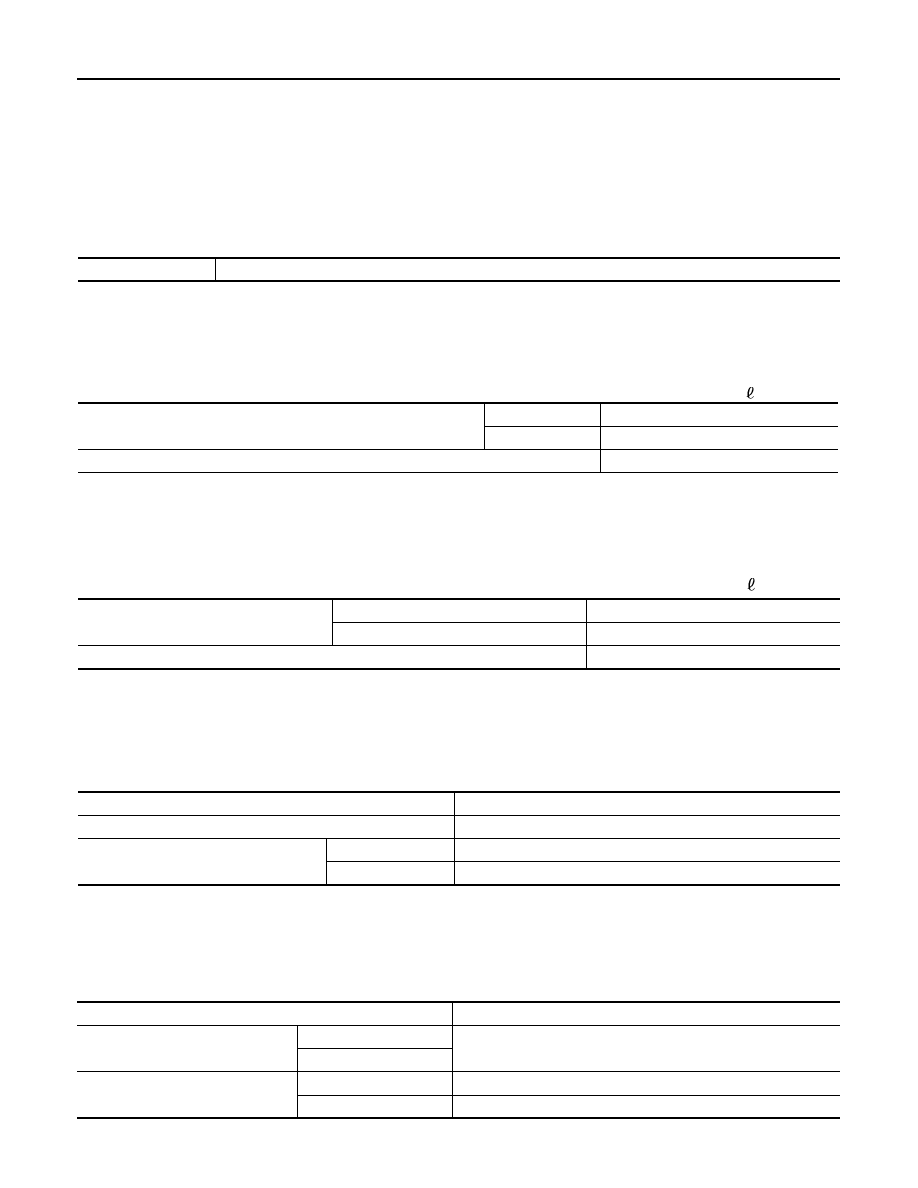

DRIVE BELT

DRIVE BELT : Drive Belt

INFOID:0000000009949453

DRIVE BELT

ENGINE COOLANT

ENGINE COOLANT : Periodical Maintenance Specification

INFOID:0000000009949454

ENGINE COOLANT CAPACITY (APPROXIMATE)

Unit:

(US qt, Imp qt)

ENGINE OIL

ENGINE OIL : Periodical Maintenance Specification

INFOID:0000000009949455

ENGINE OIL CAPACITY (APPROXIMATE)

Unit:

(US qt, lmp qt)

SPARK PLUG

SPARK PLUG : Spark Plug

INFOID:0000000009949456

SPARK PLUG

Unit: mm (in)

ROAD WHEEL

ROAD WHEEL : Road Wheel

INFOID:0000000010269337

ALUMINUM WHEEL

STEEL WHEEL

Tension of drive belt

Belt tension is not necessary, as it is automatically adjusted by drive belt auto-tensioner.

Engine coolant capacity (With reservoir tank at “MAX” level)

CVT models

7.1 (7-1/2, 6-1/4)

M/T models

6.8 (7-1/4, 6)

Reservoir tank engine coolant capacity (At “MAX” level)

0.7 (3/4, 5/8)

Drain and refill

With oil filter change

4.1 (4-3/8, 3-5/8)

Without oil filter change

3.8 (4, 3-3/8)

Dry engine (Overhaul)

4.9 (5-1/8, 4-3/8)

Make

DENSO

Standard type

FXE20HR11

Gap (Nominal)

Standard

1.1 (0.043)

Limit

1.4 (0.055)

Item

Limit

Radial runout

Axial runout

Less than 0.3 mm (0.012 in)

Radial runout

Allowable unbalance

Dynamic (At flange)

Less than 10 g (0.35 oz) (one side)

Static (At flange)

Less than 20 g (0.70 oz)