Nissan Cube. Manual - part 497

FAX-24

< REMOVAL AND INSTALLATION >

FRONT DRIVE SHAFT

c.

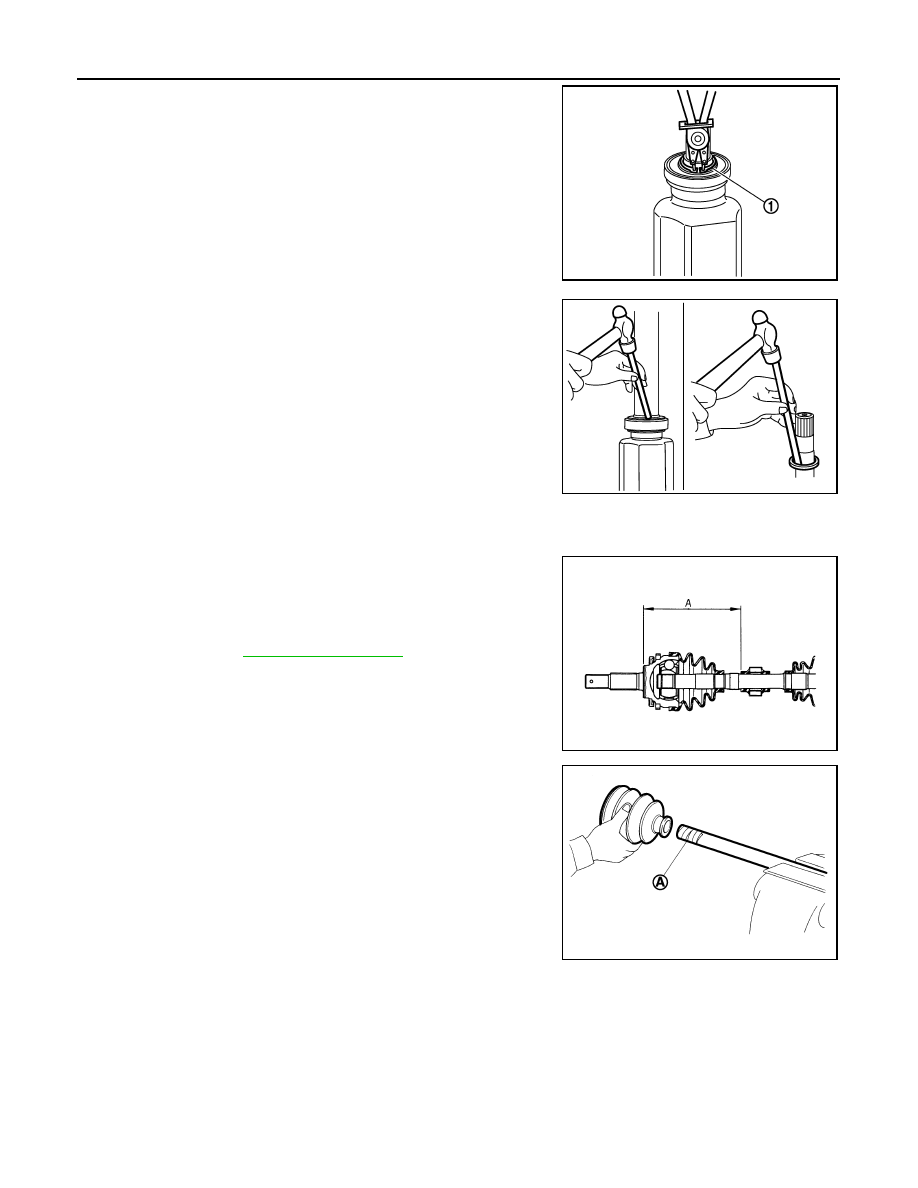

Install snap ring (1).

CAUTION:

Never reuse snap ring.

d.

Install dust shields.

CAUTION:

Never reuse dust shields.

2.

Install dynamic damper, follow the procedure described below.

a.

Install dynamic damper to shaft.

b.

Secure dynamic damper with bands in the following specified

position (A) when installing.

CAUTION:

Never reuse bands.

3.

Wrap serration on shaft with tape (A) to protect boot from dam-

age. Install new boot and boot bands to shaft.

CAUTION:

Never reuse boot and boot band.

4.

Remove the tape wrapped around the serration on shaft.

JPDIF0106ZZ

JPDIF0127ZZ

A

: Refer to

JPDIF0178ZZ

JPDIF0009ZZ