Nissan Cube. Manual - part 495

FAX-16

< REMOVAL AND INSTALLATION >

FRONT DRIVE SHAFT

LEFT SIDE

LEFT SIDE : Removal and Installation

INFOID:0000000009948799

REMOVAL

1.

Remove tires with power tool. Refer to

.

2.

Remove cotter pin, and then loosen wheel hub lock nut. Refer to

.

3.

Patch wheel hub lock nut with a piece of wood. Hammer the wood to disengage wheel hub and bearing

assembly from drive shaft.

CAUTION:

• Never place drive shaft joint at an extreme angle. Also be careful not to overextend slide joint.

• Never allow drive shaft to hang down without support for joint sub-assembly, shaft and the other

parts.

NOTE:

Use suitable puller, if wheel hub and bearing assembly and drive shaft cannot be separated even after

performing the above procedure.

4.

Remove wheel hub lock nut.

5.

Remove transverse link from steering knuckle. Refer to

.

6.

Remove shaft assembly from wheel hub and bearing assembly.

CAUTION:

Be careful not to damage front wheel sensor and harness.

7.

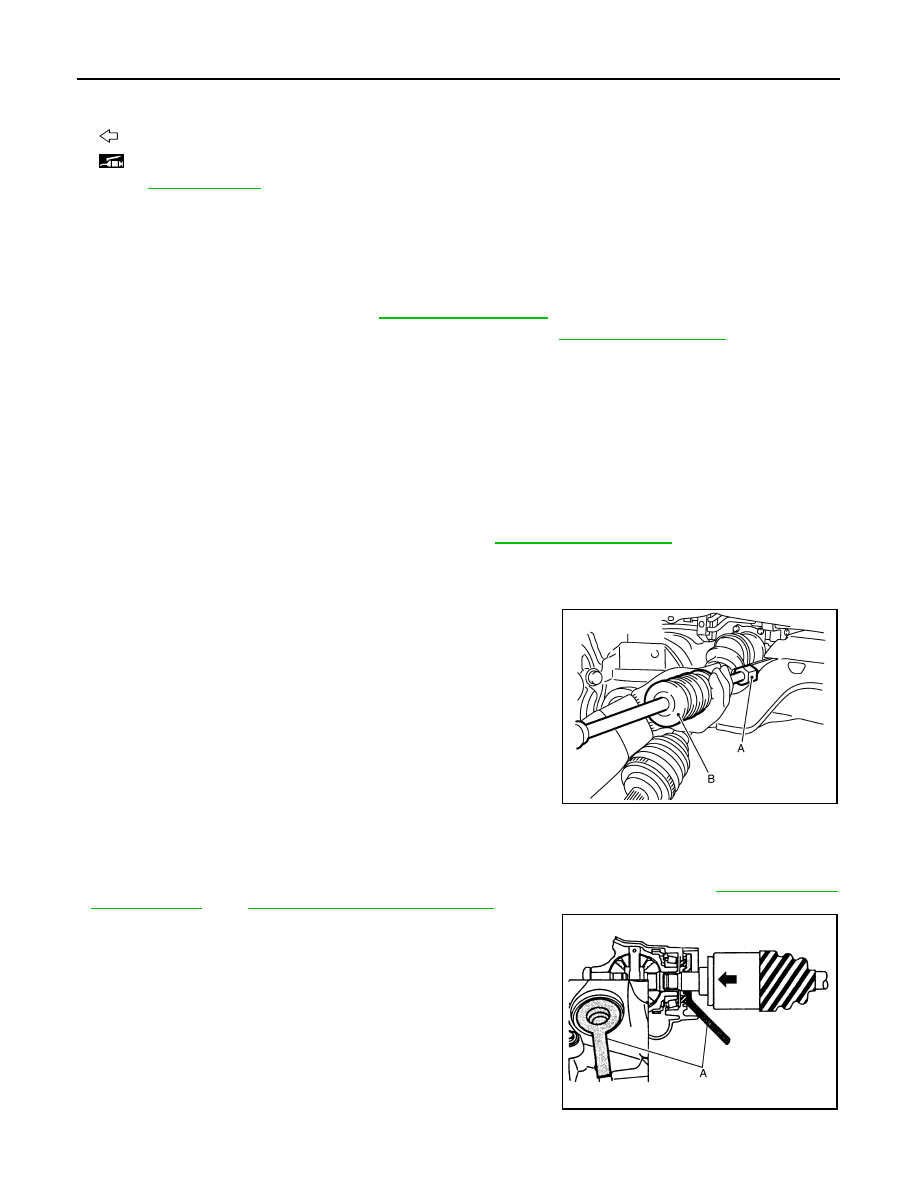

Use the drive shaft attachment [SST: KV40107500 (

—

)] (A)

and a sliding hammer (commercial service tool) (B) while insert-

ing tip of the drive shaft attachment between shaft and transaxle

assembly, and then remove drive shaft from transaxle assembly.

CAUTION:

• Never place drive shaft joint at an extreme angle when

removing drive shaft. Also be careful not to overextend

slide joint.

• Confirm that the circular clip is attached to the drive shaft.

INSTALLATION

Note the following, and install in the reverse order of removal.

Transaxle Side

• Always replace differential side oil seal with new one when installing drive shaft. Refer to

TM-229, "Removal and Installation"

• Place the protector [SST: KV38107900 (

—

)] (A) onto transaxle

assembly to prevent damage to the oil seal while inserting drive

shaft. Slide drive shaft sliding joint and tap with a hammer to install

securely.

CAUTION:

Check that circular clip is completely engaged.

Wheel Hub Side

13. Snap ring

14. Dust shield

15. Plate

16. Support bearing bracket

: Wheel side

: Fill NISSAN Genuine grease or equivalent.

Refer to

for symbols not described on the above.

JPDIF0004ZZ

JPDIF0023ZZ