Nissan Versa Note. Manual - part 789

TM-36

< UNIT DISASSEMBLY AND ASSEMBLY >

[5MT: RS5F91R]

TRANSAXLE ASSEMBLY

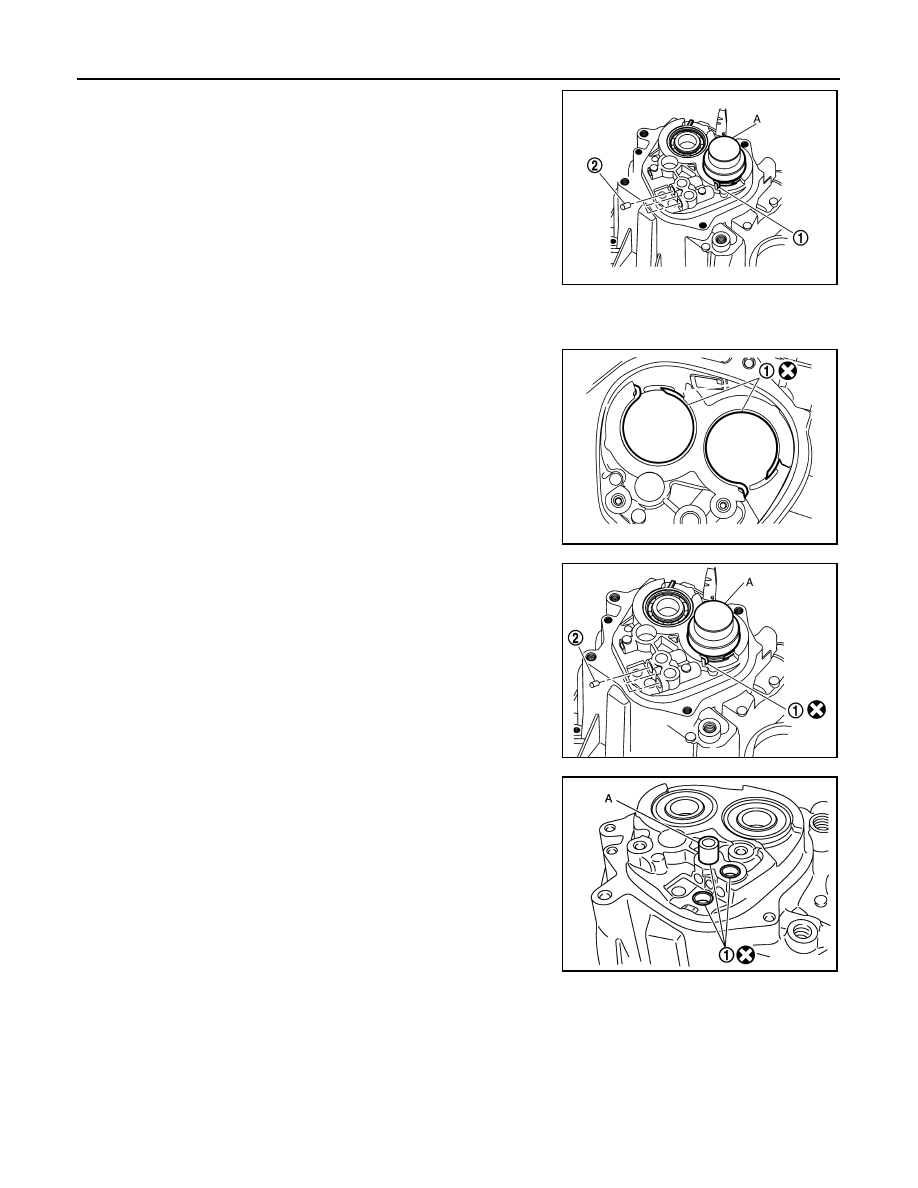

42. Expand snap rings (1) and remove input shaft rear bearing and

mainshaft rear bearing from transaxle case, using Tool (A).

43. Remove snap rings from transaxle case.

44. Remove check balls (2) from transaxle case.

Assembly

INFOID:0000000009417476

1. Install snap rings (1) along transaxle case groove so that notch

mates with housing as shown.

CAUTION:

• Do not reuse snap rings.

• Check snap ring installation direction.

• Be sure to align notch with housing.

2. Expand snap rings (1) and install input shaft rear bearing and

mainshaft rear bearing to transaxle case, using Tool (A).

CAUTION:

Check that snap ring is correctly installed within bearing

groove.

3. Install check balls (2) to transaxle case.

4. Install bushings (1) until they reach transaxle case, using suit-

able tool (A).

CAUTION:

Do not reuse bushings.

5. Apply gear oil to O-ring, and then install it to control shaft.

CAUTION:

Do not reuse O-ring.

Tool number

: ST35300000 ( — )

PCIB1535E

PCIB1547E

Tool number

: ST35300000 ( — )

PCIB1548E

JPDIC0636ZZ