Nissan Versa Note. Manual - part 374

EM-12

< BASIC INSPECTION >

[HR16DE]

CAMSHAFT VALVE CLEARANCE

3. Measure the center thickness of the removed valve lifters using

a suitable tool (A).

4. Use the equation below to calculate valve lifter thickness for replacement.

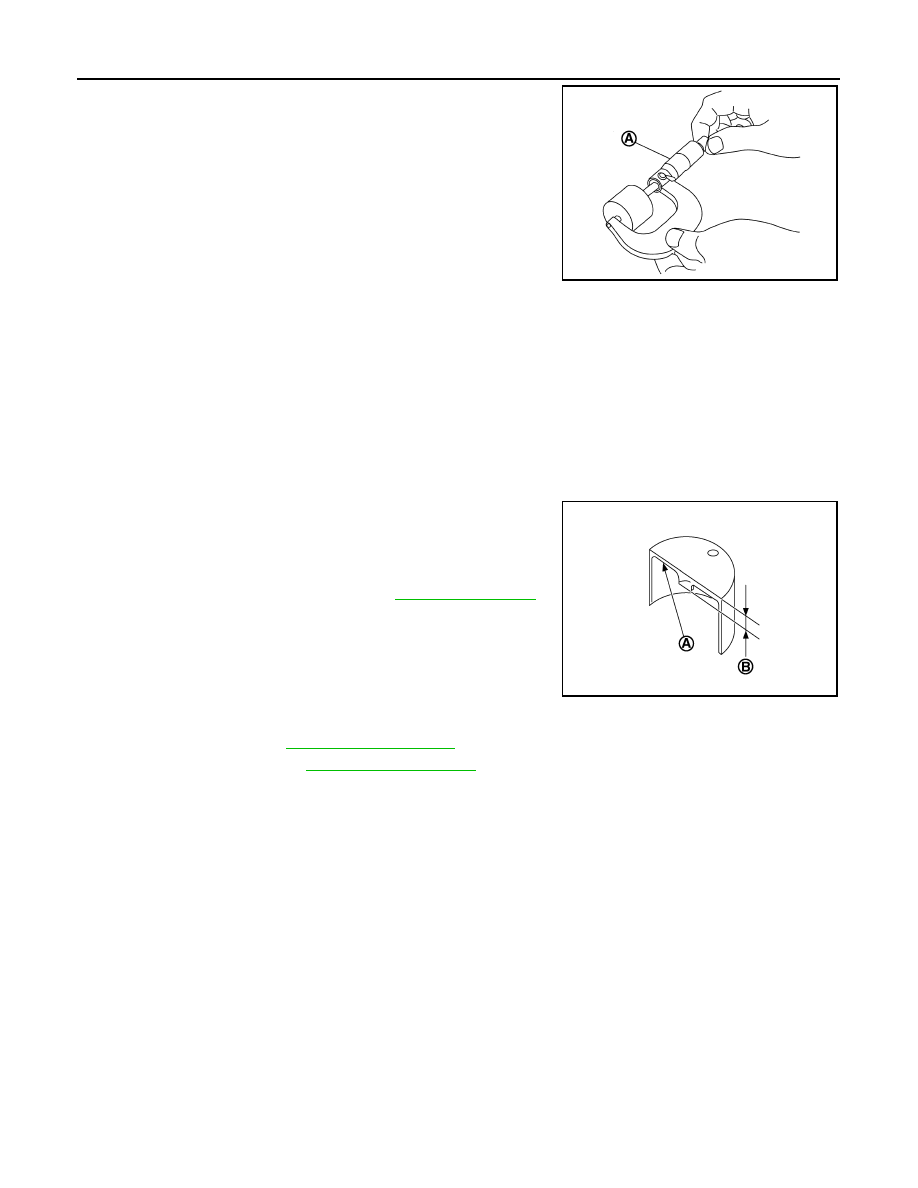

• Crown surface thickness of new valve lifter (B) can be identi-

fied by stamp mark (A) on the under side of the lifter.

NOTE:

Available thickness of valve lifter: 26 sizes range 3.00 to 3.50

mm (0.1181 to 0.1378 in) in increments of 0.02 mm (0.0008 in)

when manufactured at factory. Refer to

.

• Stamp mark “302” indicates 3.02 mm (0.1189 in) in thickness.

5. Install the correct thickness valve lifter.

6. Install camshaft. Refer to

.

7. Install timing chain. Refer to

8. Manually rotate crankshaft pulley a few rotations.

9. Check that valve clearances are within specification. Refer to “INSPECTION”.

10. Installation of remaining components is in the reverse order of removal.

11. Warm up the engine, and check for unusual noise and vibration.

PBIC3195J

Valve lifter thickness calculation:

t = t

1

+ (C

1

– C

2

)

t

= Valve lifter thickness to be replaced

t

1

= Removed valve lifter thickness

C

1

= Measured valve clearance

C

2

= Standard valve clearance at 20

°C (68°F):

Intake

: 0.30 mm (0.012 in)

Exhaust

: 0.33 mm (0.013 in)

PBIC3196J