Nissan Versa Note. Manual - part 375

EM-16

< PERIODIC MAINTENANCE >

[HR16DE]

DRIVE BELT

PERIODIC MAINTENANCE

DRIVE BELT

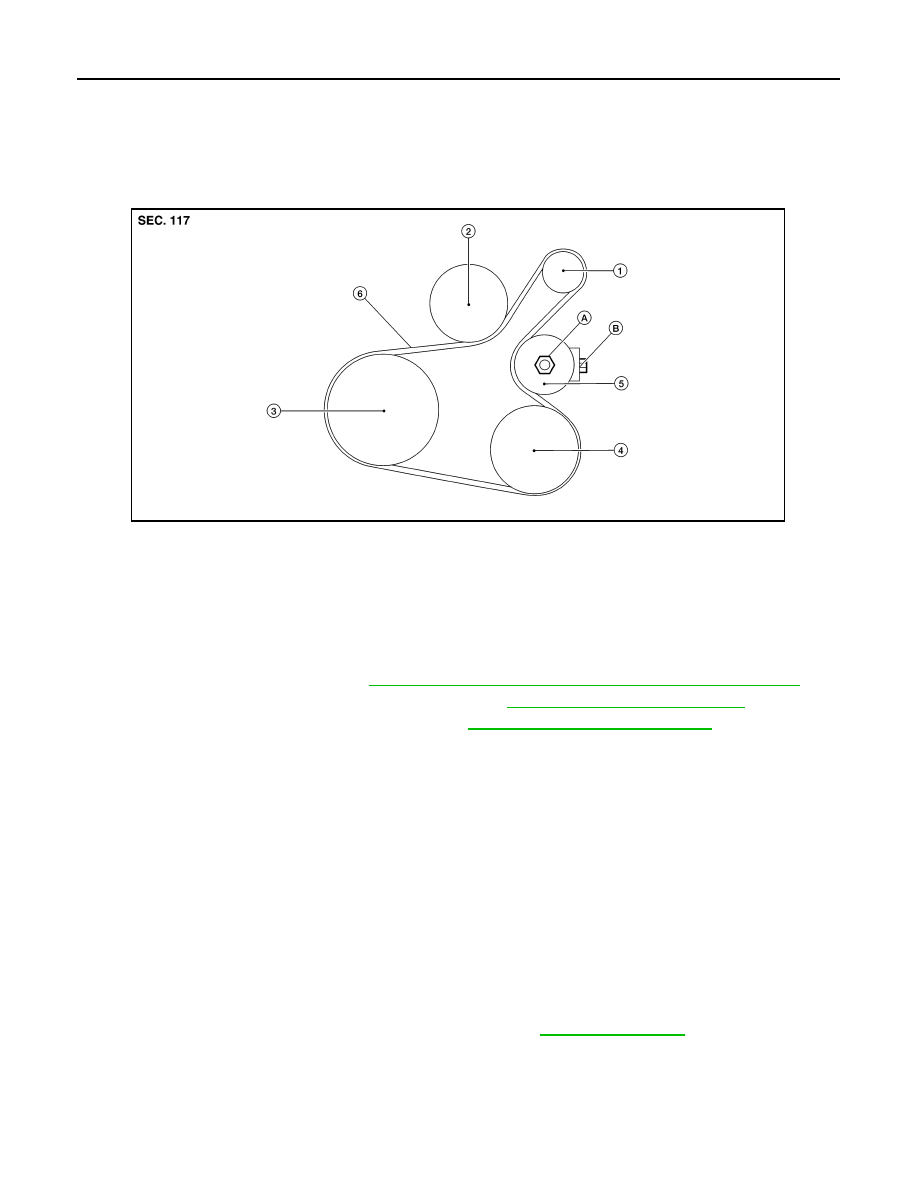

Exploded View

INFOID:0000000009444712

Removal and Installation

INFOID:0000000009444713

REMOVAL

1. Remove engine undercover. Refer to

EXT-37, "FRONT UNDER COVER : Removal and Installation"

.

2. Remove wheel and tire (RH) using a power tool. Refer to

WT-45, "Removal and Installation"

3. Partially remove the fender protector (RH). Refer to

EXT-36, "Removal and Installation"

.

4. Loosen the lock nut and then release the belt tension by turning the adjusting bolt.

5. Remove the drive belt.

INSTALLATION

1. Pull the idler pulley in the loosening direction, and then temporarily tighten the lock nut to the following

torque.

NOTE:

Do not move the lock nut from the temporary tightened position. Go to step 2.

2. Install the drive belt on each pulley.

CAUTION:

• Check that there is no engine oil, grease, or engine coolant, etc. in pulley grooves.

• Check that the belt seats securely inside the groove on each pulley.

3. Adjust drive belt tension by turning the adjusting bolt. Refer to

CAUTION:

• Perform the belt tension adjustment with the lock nut temporarily tightened to the torque specifi-

cation listed in step 1 which prevents the idler pulley from tilting.

• When checking immediately after installation, first adjust it to the specified value. Then, after

turning crankshaft two turns or more, readjust to the specified value to avoid variation in deflec-

tion between pulleys.

1.

Generator

2.

Water pump

3.

Crankshaft pulley

4.

A/C compressor (with A/C models)

Idler pulley (without A/C models)

5.

Tensioner idler pulley

6.

Drive belt

ALBIA1157ZZ

Lock nut

(Temporary tightening)

: 4.4 N·m (0.45 kg-m, 39 in-lb)