Nissan Rogue. Manual - part 693

FRONT DRIVE SHAFT

FAX-65

< UNIT DISASSEMBLY AND ASSEMBLY >

[AWD]

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

UNIT DISASSEMBLY AND ASSEMBLY

FRONT DRIVE SHAFT

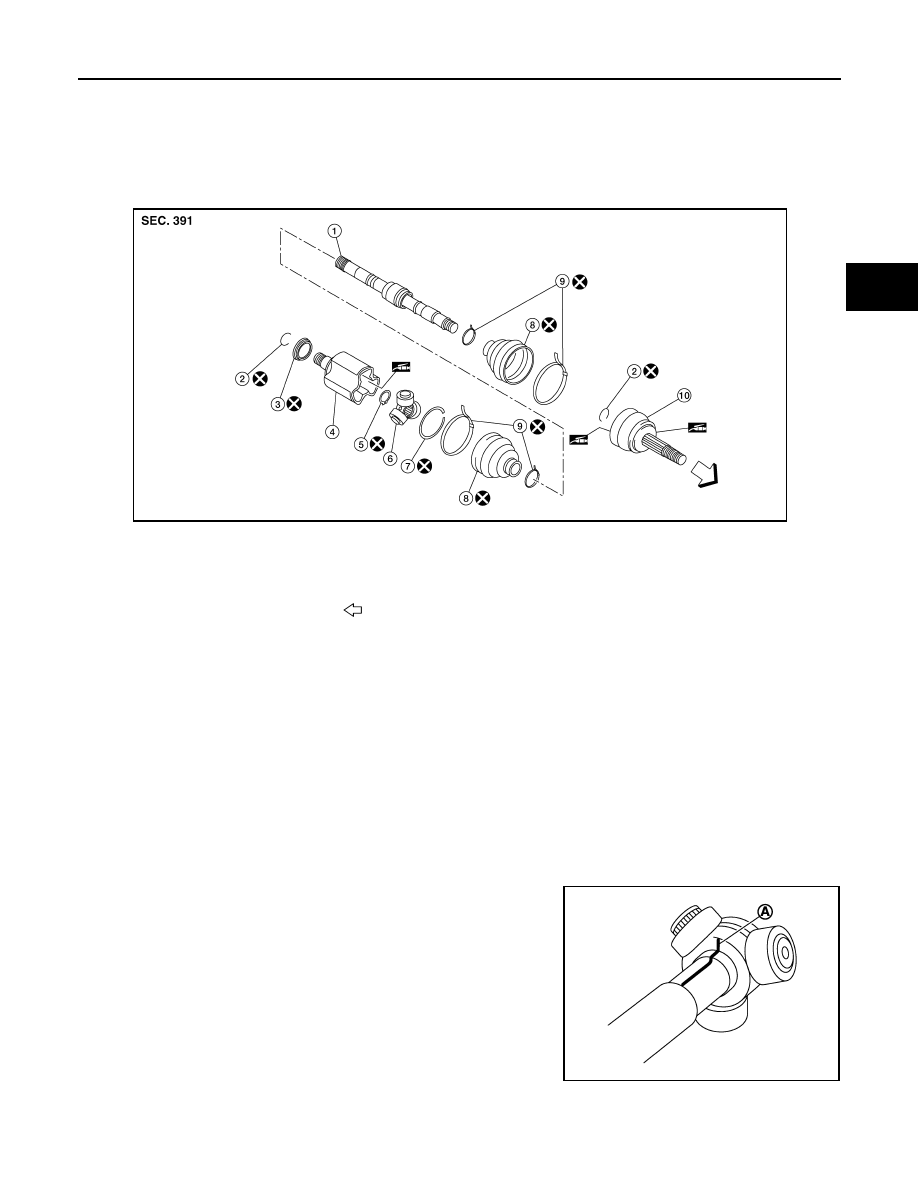

Exploded View (LH)

INFOID:0000000011278659

Disassembly and Assembly (LH)

INFOID:0000000011278660

DISASSEMBLY

Transaxle Side

1. Secure front drive shaft in a vise.

CAUTION:

When securing shaft in a vise, always use copper or aluminum plates between the vise and shaft.

2. Remove boot bands and slide the boot back.

3. Remove stopper ring.

4. Put matching marks on housing and shaft, and then pull out housing from shaft.

CAUTION:

Use paint or an equivalent for matching marks. Do not scratch the surfaces.

5. Put matching marks (A) on the spider assembly and shaft.

CAUTION:

Use paint or an equivalent for matching marks. Do not

scratch the surfaces.

1.

Shaft

2.

Circular clip

3.

Dust shield

4.

Housing

5.

Snap ring

6.

Spider assembly

7.

Stopper ring

8.

Boot

9.

Boot band

10. Joint sub-assembly

Wheel side

AWDIA1161ZZ

JPDIF0006ZZ