Nissan Rogue. Manual - part 691

FRONT DRIVE SHAFT

FAX-57

< REMOVAL AND INSTALLATION >

[AWD]

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

FRONT DRIVE SHAFT

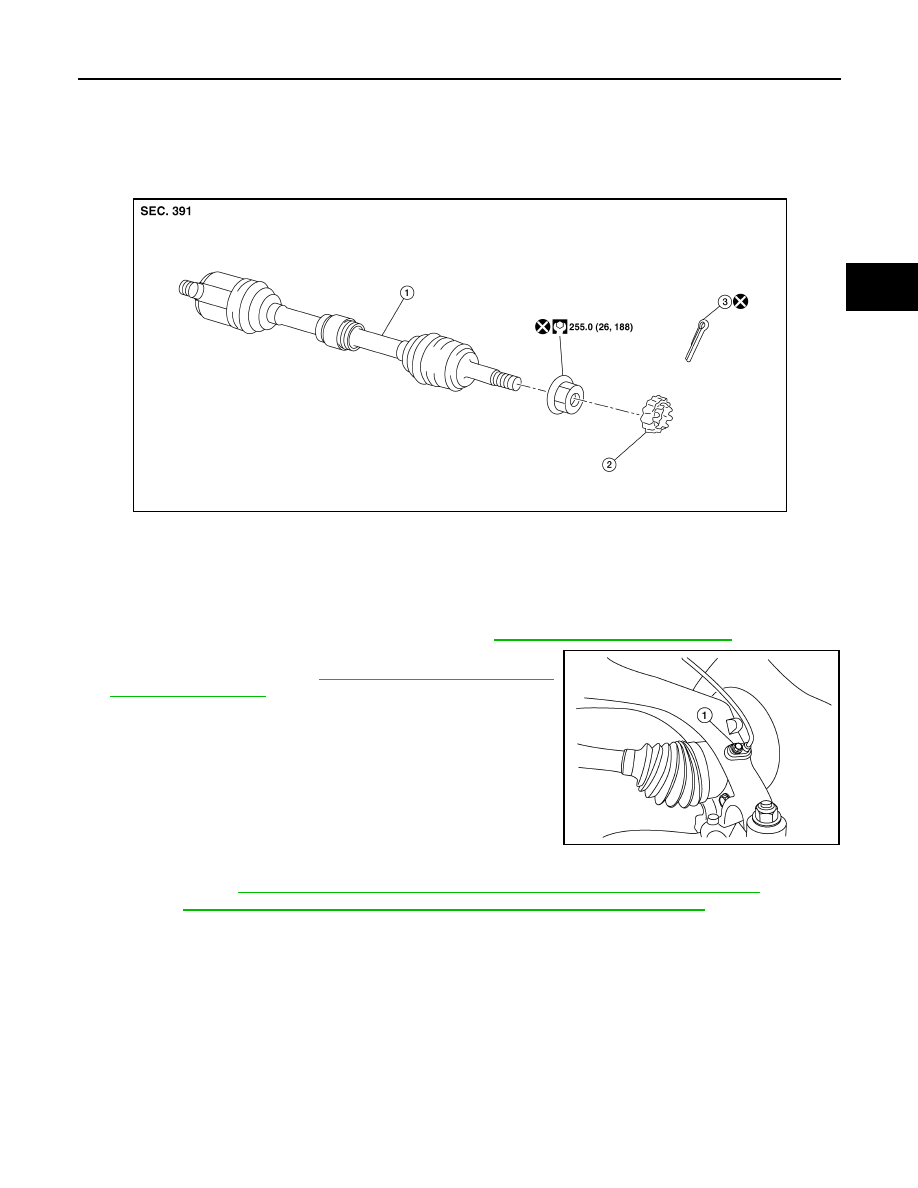

Exploded View (LH)

INFOID:0000000011278654

Removal and Installation (LH)

INFOID:0000000011278655

REMOVAL

1. Remove front wheel and tire using power tool. Refer to

WT-67, "Removal and Installation"

2. Remove the bolt (1) and separate the front wheel sensor from

the steering knuckle. Refer to

.

CAUTION:

• Failure to separate the front wheel sensor from the steer-

ing knuckle may result in damage to the front wheel sen-

sor.

• Pull out the front wheel sensor, being careful to turn it as

little as possible. Do not pull on wheel sensor harness.

3. Remove brake caliper torque member bolts, leaving brake hose attached. Position the brake caliper aside

BR-37, "BRAKE CALIPER ASSEMBLY (1 PISTON TYPE) : Exploded View"

(1 PISTON

TYPE), or

BR-42, "BRAKE CALIPER ASSEMBLY (2 PISTON TYPE) : Exploded View"

(2 PISTON TYPE).

CAUTION:

Do not depress brake pedal while brake caliper is removed.

1.

Drive shaft

2.

Nut retainer

3.

Cotter pin

AWDIA1204ZZ

ALDIA0526ZZ