Nissan Rogue. Manual - part 575

CYLINDER HEAD

EM-65

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

d. Finish valve seat to the specified dimension using suitable tool.

CAUTION:

When using valve seat cutter, firmly grip the cutter handle

with both hands. Then, press on the contacting surface all

around the circumference to cut in a single drive. Improper

pressure on the cutter or cutting many different times may

result in stage valve seat.

e. Using compound, grind to adjust valve.

f.

Check again for normal contact. Refer to

.

3. Apply new engine oil to new valve oil seal joint surface and seal lip.

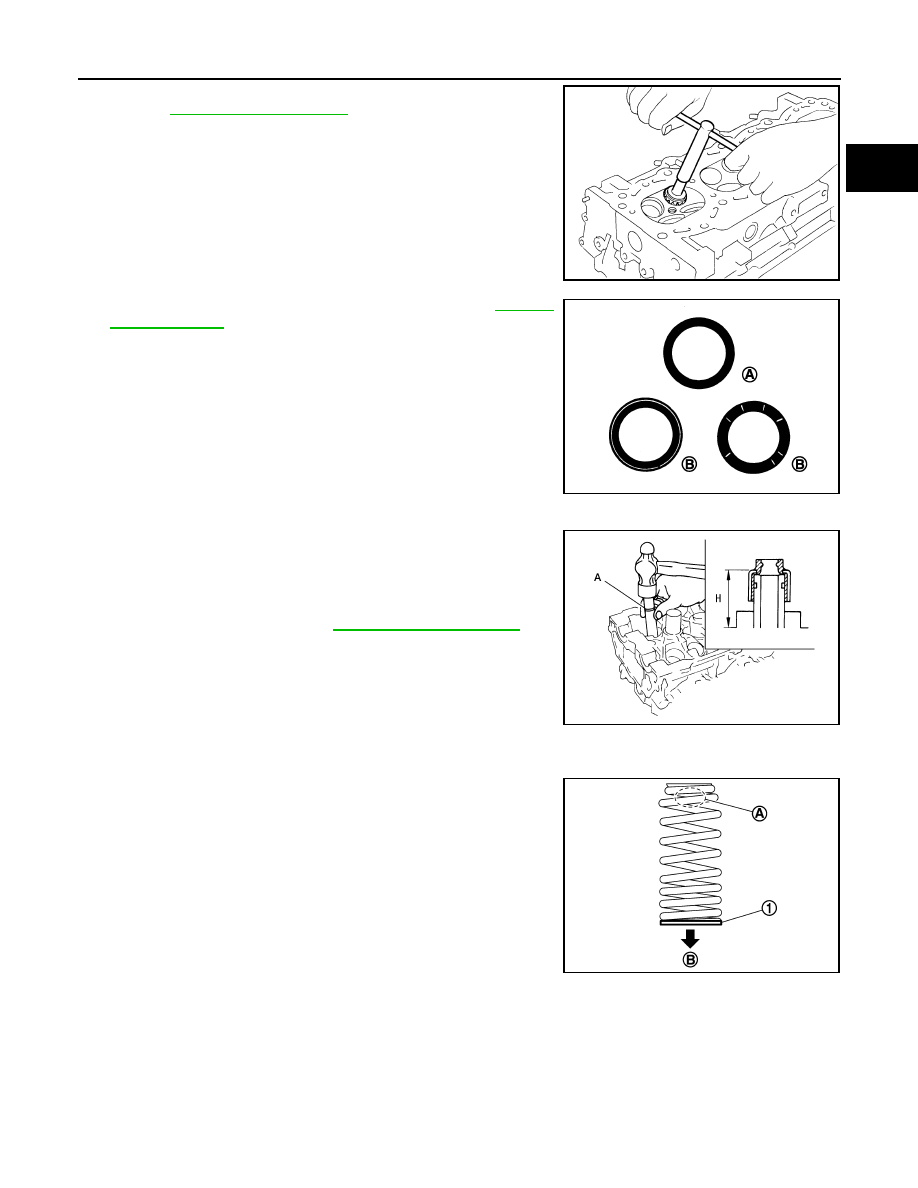

4. Install new valve oil seal using suitable tool (A) as shown.

NOTE:

Dimension is height measured before installing valve spring

(with valve spring seat).

5. Install valve.

• Install larger diameter to intake side.

6. Install valve spring with valve spring seat (1).

• Install valve spring so that the identification color faces upward

(A).

• Install smaller pitch to cylinder head side (B).

• Confirm the identification color of the valve spring.

7. Install valve spring retainer.

8. Install valve collet.

SEM934C

(A)

: OK

(B)

: NG

JPBIA0187ZZ

Projection (H)

: Refer to

ALBIA0864GB

Intake

: White

Exhaust

: Light blue

JPBIA4479ZZ