Nissan Rogue. Manual - part 574

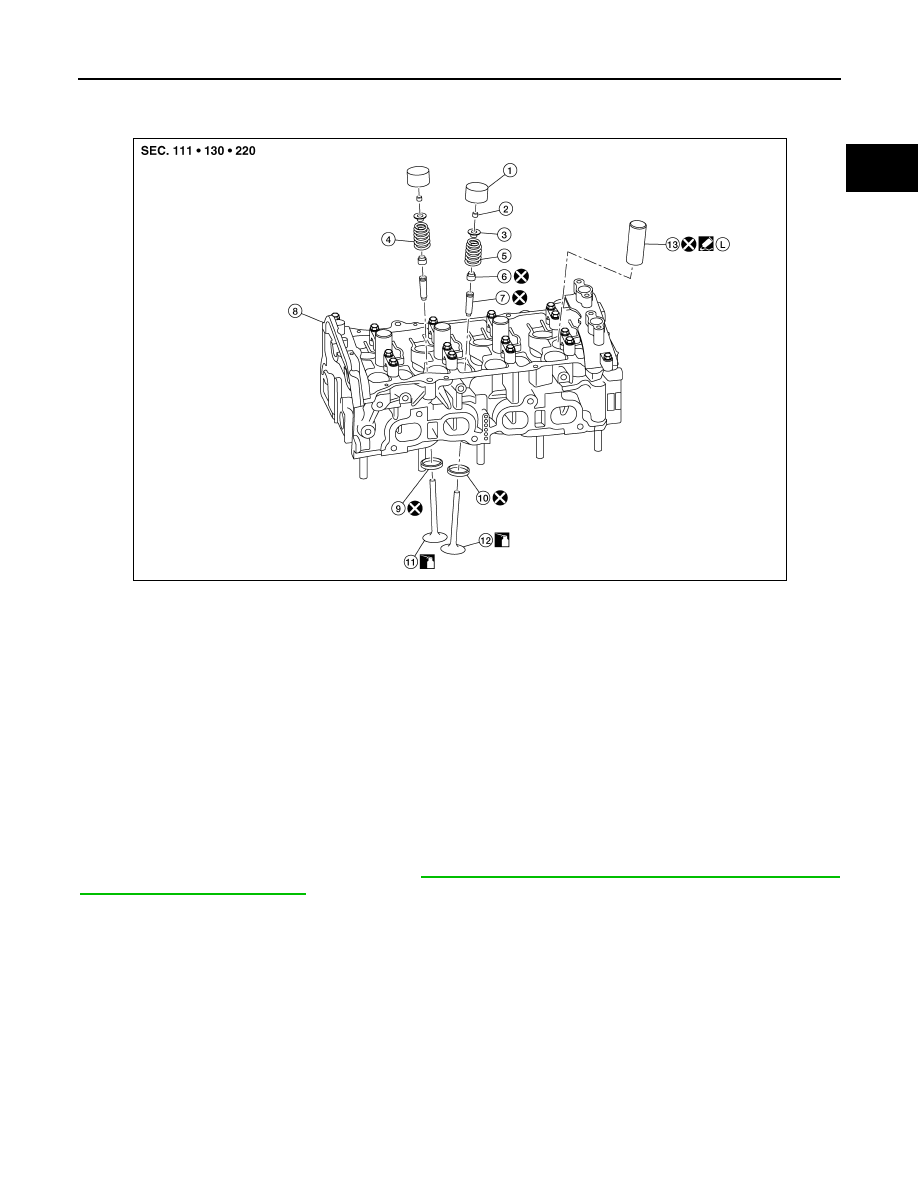

CYLINDER HEAD

EM-61

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Disassembly and Assembly

INFOID:0000000011279964

CAUTION:

• When installing camshafts, chain tensioners, oil seals or other sliding parts, lubricate contacting

surfaces with new engine oil.

• Apply new engine oil to threads and seat surfaces when installing the cylinder head, camshaft

sprocket, crankshaft pulley and camshaft bracket.

• Attach tags to valve lifters so all parts are assembled in their original position.

CAUTION:

Read PRECAUTION carefully.

The exhaust valve contains metallic sodium. Therefore, extreme caution must be taken when handling

and disposing of the exhaust valve. Refer to

EM-4, "Special Cautions to Ensure the Safe Disposal of

DISASSEMBLY

1. Remove the valve lifter.

NOTE:

Confirm installation point to return valve lifter to original location during assembly.

1.

Valve lifter

2.

Valve collet

3.

Valve spring retainer

4.

Valve spring (INT)

5.

Valve spring (EXH)

6.

Valve oil seal

7.

Valve guide

8.

Cylinder head

9.

Valve seat (INT)

10. Valve seat (EXH)

11. Valve (INT)

12. Valve (EXH)

13. Spark plug tube

L

Apply thread locking sealant

AWBIA1924ZZ