Nissan Rogue. Manual - part 573

TIMING CHAIN

EM-57

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

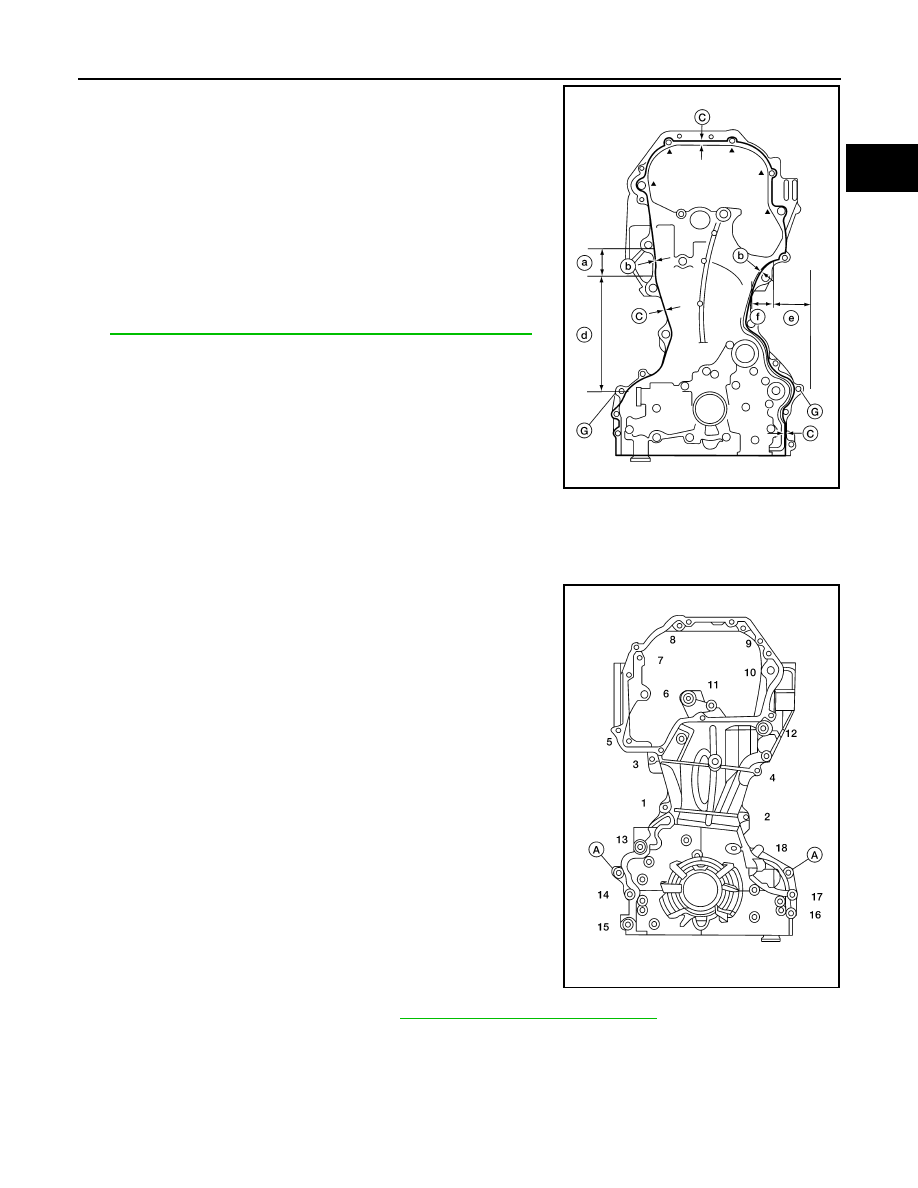

b. Apply a continuous bead of liquid gasket to front cover as

shown.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-22, "Recommended Chemical Products and Sealants"

.

CAUTION:

• Be sure sealant surfaces are free from grease, dirt, water,

and engine oil.

• Be sure to apply sealant without breaks or overlap.

• Installation should be done within 5 minutes after applica-

tion of liquid gasket.

• Do not fill the engine with engine oil for at least 30 min-

utes after the components are installed to allow the liquid

gasket to cure.

c. Make sure the mating marks on the timing chain and each sprocket are still aligned. Then install the front

cover.

CAUTION:

Do not damage the front oil seal during installation.

d. Tighten front cover bolts in the numerical order shown.

e. After all bolts are tightened, retighten them to the specified

torque.

CAUTION:

Wipe off excess sealant leaking at the surface for installing

the oil pan.

10. Install the chain guide between the camshaft sprockets.

11. Install valve timing control cover. Refer to

EM-80, "Valve Timing Control Cover"

12. Insert crankshaft pulley by aligning with crankshaft key.

• Tap its center with a plastic hammer to insert.

CAUTION:

• Do not hit belt mounting section with hammer to avoid breaking belt guide.

• Be sure not to damage front oil seal while installing crankshaft pulley.

(a)

: 35.7 mm (1.406 in)

(b)

: 6.0 – 7.0 mm (0.236 – 0.276 in)

(c)

: 3.4 – 4.4 mm (0.134 – 0.173 in)

(d)

: 179.6 mm (7.07 in)

(e)

: 35.5 mm (1.398 in)

(f)

: 31.3 mm (1.232 in)

(G) : Dowel pin hole

ALBIA0943ZZ

Front cover bolts

Bolts 6, 10, 12

: 49 N·m (5.0 kg-m, 36 ft-lb)

Bolts (all remaining) : 12.8 N·m (1.3 kg-m, 9 ft-lb)

(A)

: Dowel pin

ALBIA0944ZZ