Nissan Rogue. Manual - part 410

DLN-84

< UNIT DISASSEMBLY AND ASSEMBLY >

[TRANSFER: TY21C]

DRIVE PINION

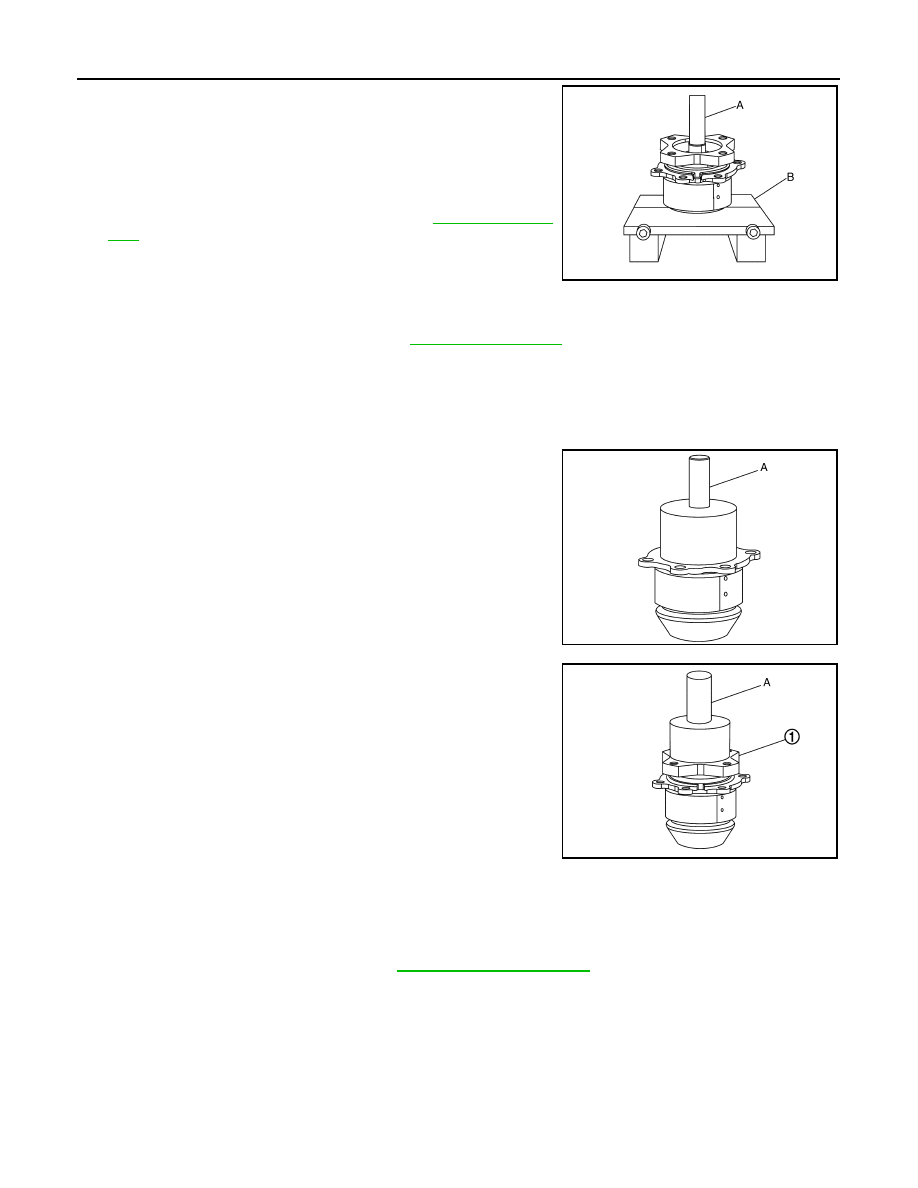

5. Remove drive pinion from pinion bearing assembly using suit-

able tool (A) and suitable tool (B).

6. Remove adjusting shim.

7. Remove companion flange.

8. Remove the dust cover.

9. Remove the oil seal.

10. Perform inspection after disassembly. Refer to

Assembly

INFOID:0000000011278375

1. Select drive pinion adjusting shim. Refer to

.

2. Assemble the selected drive pinion adjusting shim to drive pinion.

3. Install the drive pinion to pinion bearing assembly using suitable tool.

CAUTION:

• Do not reuse pinion bearing assembly.

• Apply gear oil to pinion bearing part.

4. Install oil seal to pinion bearing assembly using suitable tool (A).

CAUTION:

• Do not reuse the oil seal.

• When installing, do not incline oil seal.

• Apply multi-purpose grease onto oil seal lips, and gear oil

onto the circumference of the oil seal.

5. Install dust cover.

NOTE:

Tighten dust cover together with pinion bearing assembly.

6. Install companion flange (1) to pinion bearing using suitable tool

(A).

7. Apply anti-corrosive oil to the thread and seat of the lock nut,

and adjust the pinion lock nut tightening torque and pinion bear-

ing preload torque, using a preload gauge.

a. Install pinion lock nut, and then tighten to the specified torque.

CAUTION:

• Do not reuse pinion lock nut.

• Check that pinion lock nut is seated on the companion flange.

b. After tightening pinion lock nut to the specified torque, retighten the pinion lock nut by 25 degrees.

c.

Measure the pinion bearing preload.

8. Apply multi-purpose grease lightly and evenly onto an O-ring, and install it to the pinion bearing assembly.

CAUTION:

• Do not reuse O-ring.

• When installing O-ring, do not use a suitable tool.

• Do not damage O-ring.

JSDIA3953ZZ

JSDIA3996ZZ

Pinion lock nut

tightening torque

: 90

±9 N·m (9.2±0.92kg-m, 66±7 ft-lb)

Pinion bearing preload

: Refer to

.

JSDIA3997ZZ