Content .. 1177 1178 1179 1180 ..

Nissan Maxima. Manual - part 1179

TM-180

< REMOVAL AND INSTALLATION >

[CVT: RE0F09B]

CONTROL VALVE

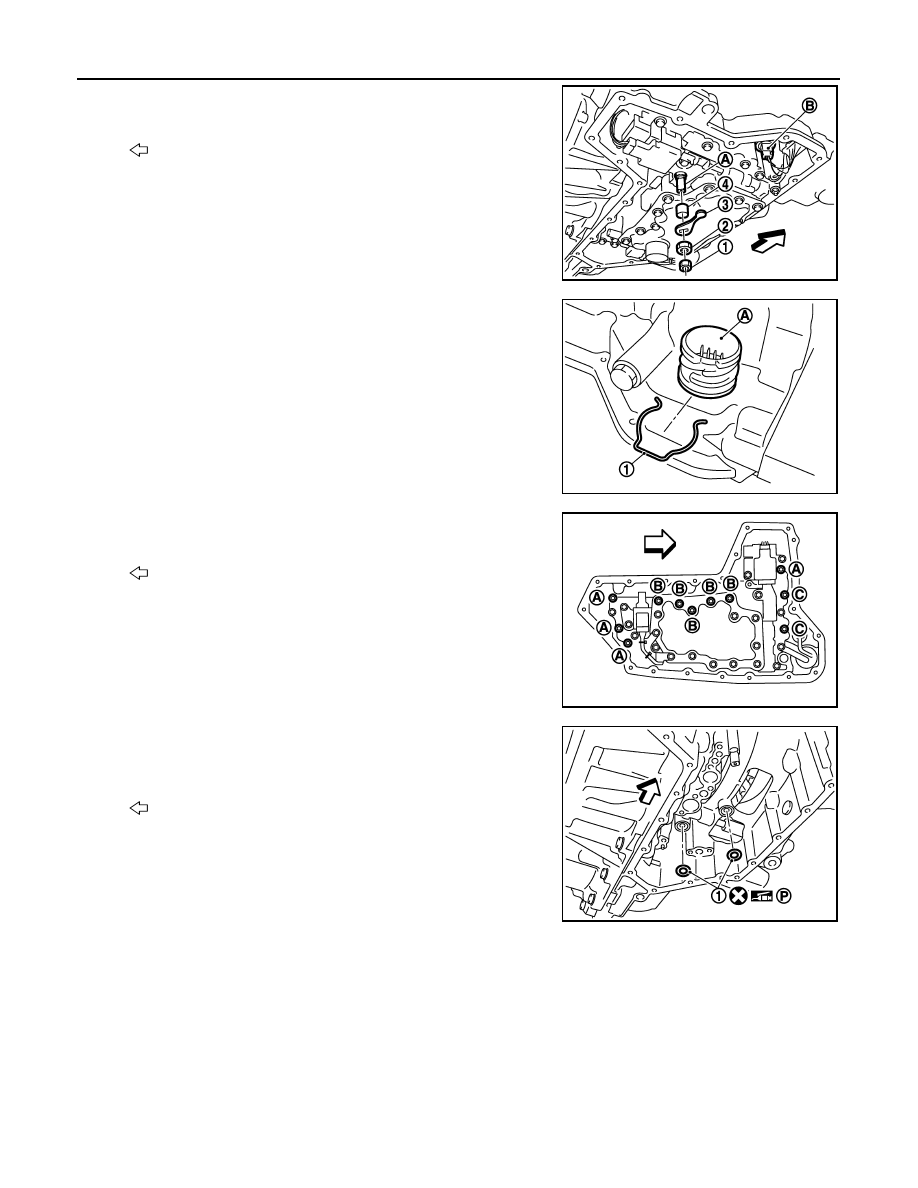

6. Remove the lock nut (1) and (2), and then remove manual plate

(3).

7. Remove the collar (4) from the manual shaft (A).

CAUTION:

Do not drop the collar.

8. Disconnect the primary pressure sensor harness connector (B).

9. Remove the snap ring (1) from the CVT unit harness connector

(A).

10. Press the CVT unit harness connector (A) into the transaxle

case.

CAUTION:

Do not damage the CVT unit harness connector.

NOTE:

Clean around the CVT unit harness connector to prevent foreign

materials from entering into the transaxle case.

11. Remove the control valve bolts (A), (B) and (C), and then

remove the control valve from the transaxle case.

CAUTION:

• Do not drop the control valve, ratio control valve and

manual shaft.

• Confirm position of the shift link for ease of installation.

12. Remove the lip seal (1) from the transaxle case.

CAUTION:

Do not reuse lip seal.

INSTALLATION

: Front

SCIA8137J

SCIA8138J

: Front

SCIA8139J

: Front

SCIA8140J