Nissan Altima HL32 Hybrid. Manual - part 657

P0A94-442

HBC-377

< COMPONENT DIAGNOSIS >

D

E

F

G

H

I

J

K

L

M

A

B

HBC

N

O

P

• After disconnecting the service plug grip, wait for at least 10 minutes before touching any of the high-voltage

connectors or terminals.

• Waiting for at least 10 minutes is required to discharge the high-voltage capacitor inside the inverter with

converter assembly.

>> GO TO 2.

2.

CHECK DTC OUTPUT (HYBRID SYSTEM)

1. Turn ignition switch ON.

2. Check DTC.

NOTE:

P0A94-442 may be set due to a malfunction which also causes DTCs in the table above to be set. In this

case, first troubleshoot the output DTCs in the table above.

Then, perform a test to attempt to reproduce the problems, and check that no DTCs are output.

Is DTC detected?

YES

>> Go to Diagnosis Procedure relevant to output DTC.

NO

>> GO TO 3.

3.

CHECK CONNECTOR CONNECTION CONDITION (INVERTER WITH CONVERTER ASSEMBLY CON-

NECTOR)

HBC-109, "Diagnosis Procedure"

OK or NG

OK

>> Replace inverter with converter assembly (See

HBC-638, "Removal and Installation"

).

NG

>> Connect securely.

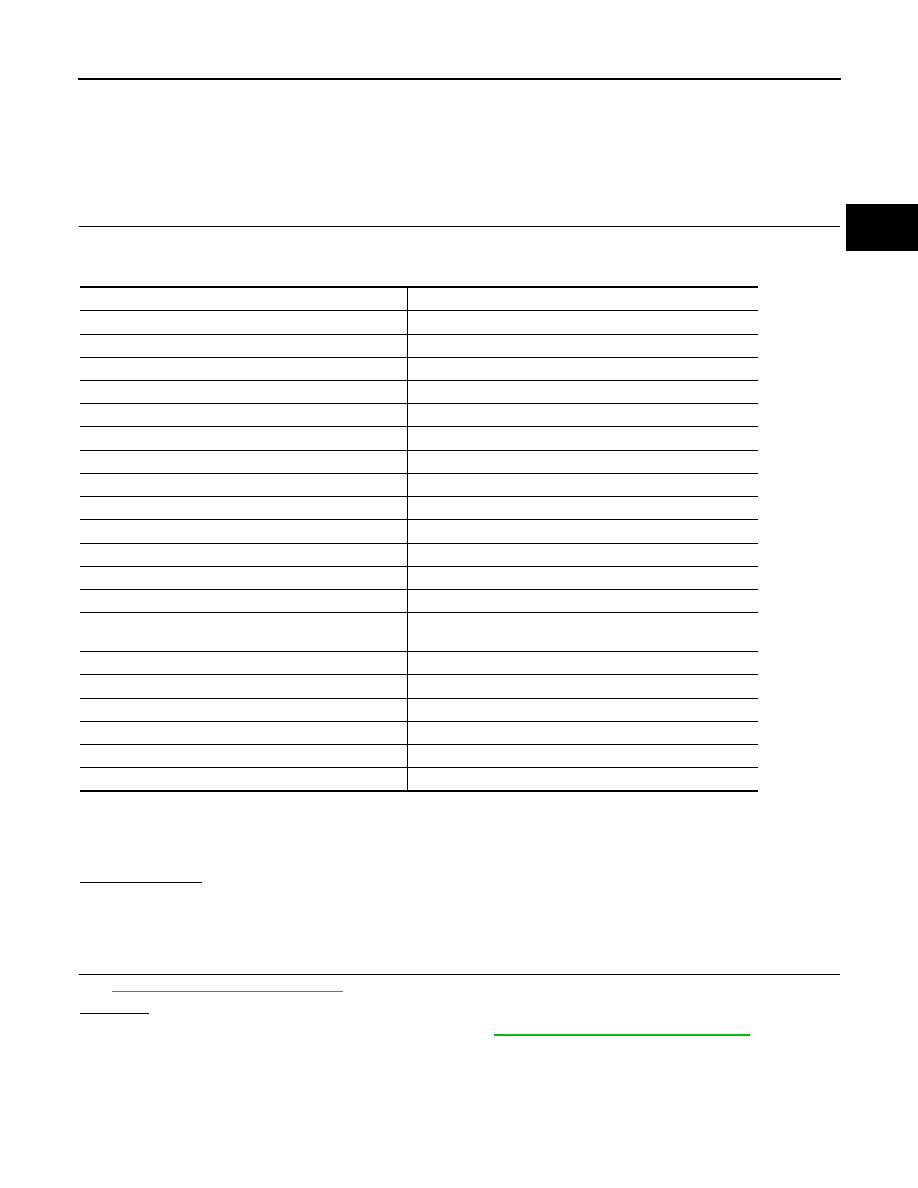

DTC No.

Relevant Diagnosis

P0A1D (Except INF code 390)

Hybrid Powertrain Control Module

P0A1A (all INF codes)

Generator Control Module

P0A1B (all INF codes)

Drive Motor “A” Control Module

P0A72 (all INF codes)

Generator Phase V Current

P0A75 (all INF codes)

Generator Phase W Current

P0A60 (all INF codes)

Drive Motor “A” Phase V Current

P0A63 (all INF codes)

Drive Motor “A” Phase W Current

P0A4B-253

Generator Position Sensor Circuit

P0A4D-255

Generator Position Sensor Circuit Low

P0A4C-513

Generator Position Sensor Circuit Range/Performance

P0A3F-243

Drive Motor “A” Position Sensor Circuit

P0A41-245

Drive Motor “A” Position Sensor Circuit Low

P0A40-500

Drive Motor “A” Position Sensor Circuit Range / Performance

P0A78-266, 267, 306, 510, 523, 586, 505, 287, 506, 503,

279, 504, 806, 807, 808

Drive Motor “A” Inverter Performance

P0A94-585, 587, 589, 590, 554, 555, 556, 547, 548, 549 DC/DC Converter Performance

P0A7A-517, 325, 344, 518, 522, 809, 810, 811

Generator Inverter Performance

P0A92 (all INF codes)

Hybrid Generator Performance

P0A90 (all INF codes)

Hybrid Generator Performance

P0AA6 (all INF codes)

Hybrid Battery Voltage System Isolation Fault

P3000 (all INF codes)

HV Battery Malfunction