Nissan Altima HL32 Hybrid. Manual - part 292

EC-152

< COMPONENT DIAGNOSIS >

[QR25DE]

P0101 MAF SENSOR

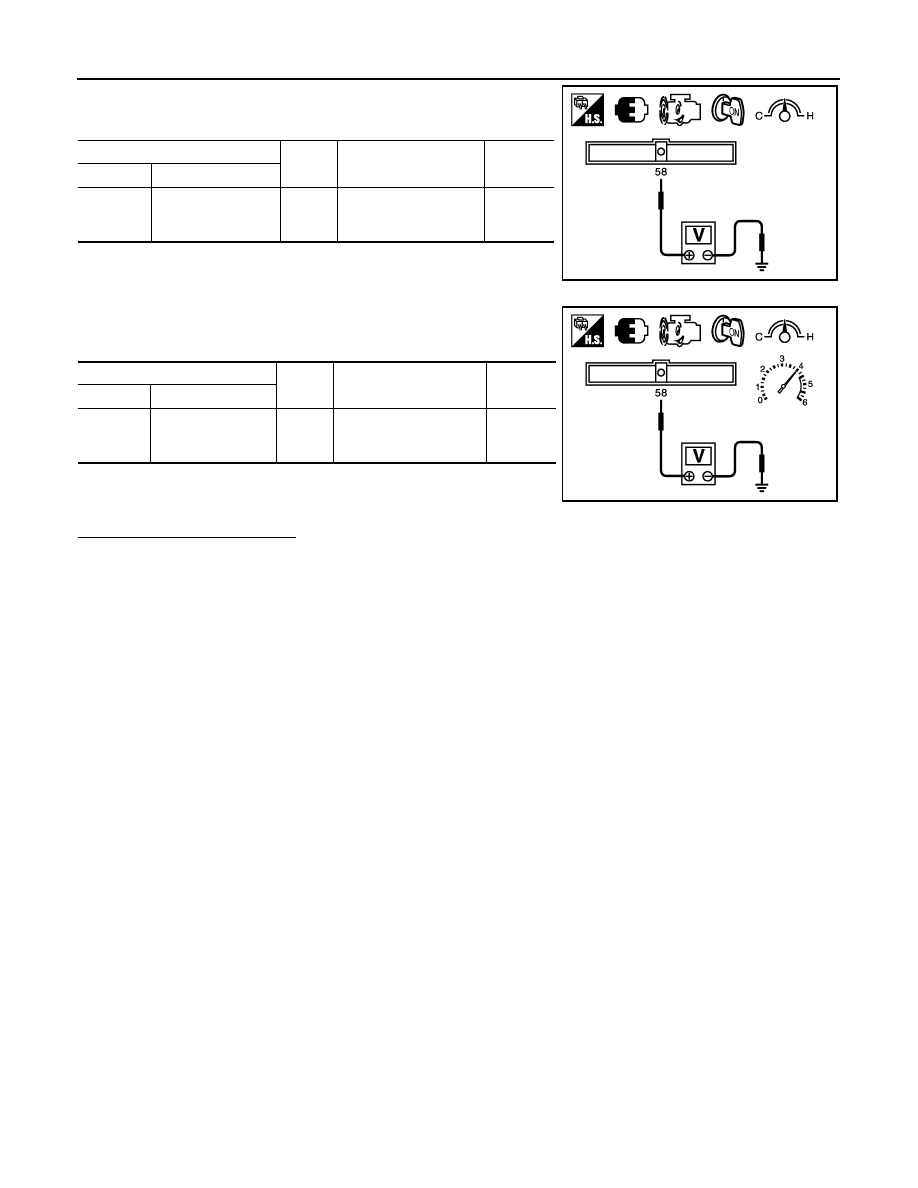

9. Check the voltage between ECM harness connector and

ground.

10. Shift the selector lever to P position.

11. Fully depress the accelerator pedal and keep it.

12. Check the voltage between ECM harness connector and

ground.

13. Fully release accelerator pedal then fully depress it.

14. Check for linear voltage rise in response to engine being

increased to about 2,500 rpm.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Clean or replace mass air flow sensor.

ECM

Ground

Condition

Voltage

Connector

Terminal

F13

58

(MAF sensor signal)

Ground

Idle (Engine is warmed-

up to normal operating

temperature.)

0.9 - 1.2 V

JMBIA1632ZZ

ECM

Ground

Condition

Voltage

Connector

Terminal

F13

58

(MAF sensor signal)

Ground

2,500 rpm (Engine is

warmed-up to normal op-

erating temperature.)

1.5 - 1.8 V

JMBIA1633ZZ