Nissan Frontier. Manual - part 721

CYLINDER HEAD

EM-73

< REMOVAL AND INSTALLATION >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

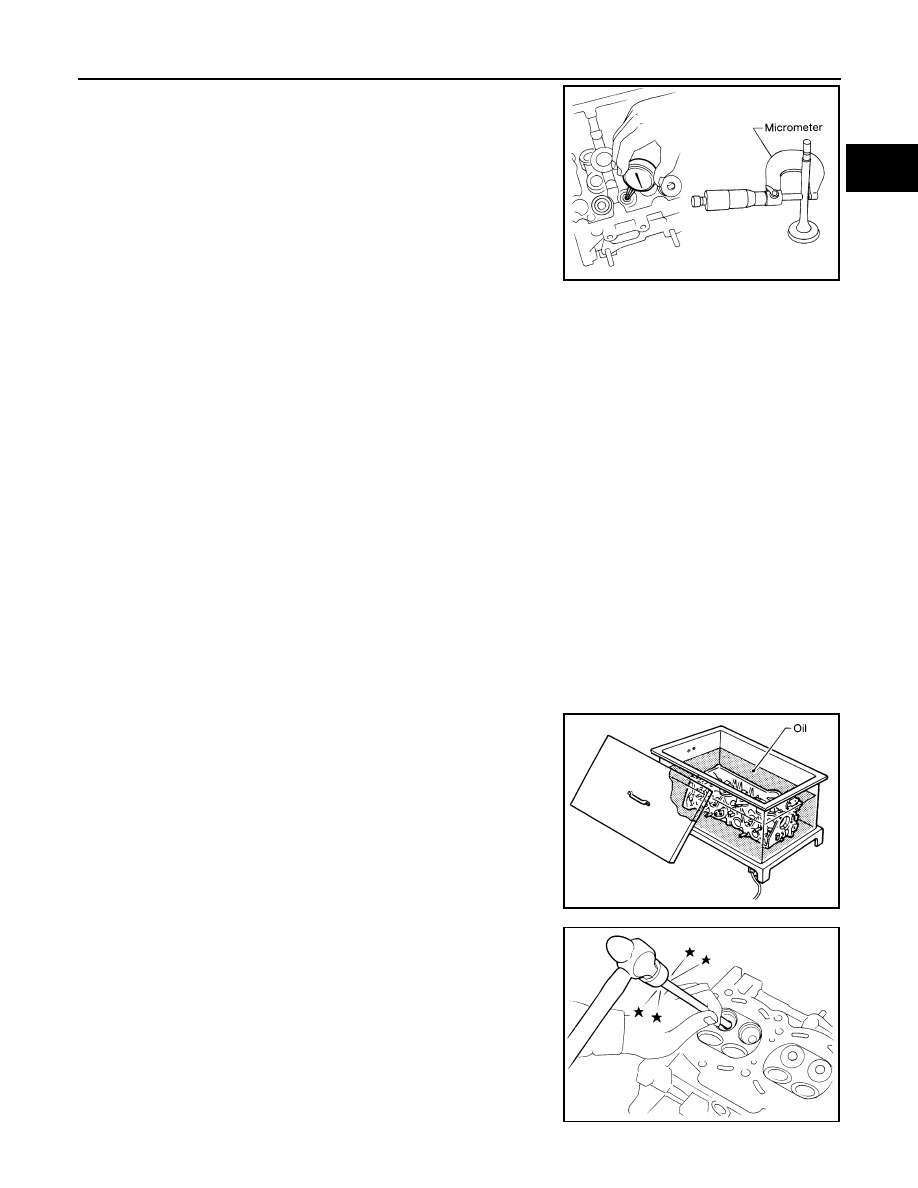

Measure the diameter of valve stem with micrometer.

Valve Guide Inner Diameter

Measure the inner diameter of valve guide with inside micrometer.

Valve Guide Clearance

(Valve guide clearance) = (Valve guide inner diameter) – (Valve stem diameter).

• If it exceeds the limit, replace valve guide and/or valve.

VALVE GUIDE REPLACEMENT

When valve guide is removed, replace with oversized [0.2 mm (0.008 in)] valve guide.

1. To remove valve guide, heat cylinder head to 110

° to 130°C

(230

° to 266°F) by soaking in heated oil.

2. Drive out valve guide with a press [under a 20 kN (2 ton, 2.2 US

ton, 2.0 lmp ton) force] or suitable tool.

WARNING:

Cylinder head contains heat, when working, wear protective

equipment to avoid getting burned.

Standard

Intake

: 5.965 - 5.980 mm (0.2348 - 0.2354 in)

Exhaust

: 5.955 - 5.970 mm (0.2344 - 0.2350 in)

SEM938C

Standard

Intake and Exhaust

: 6.000 - 6.018 mm (0.2362 - 0.2369 in)

Valve guide clearance:

Standard

Intake

: 0.020 - 0.053 mm (0.0008 - 0.0021 in)

Exhaust : 0.030 - 0.063 mm (0.0012 - 0.0025 in)

Limit

Intake

: 0.08 mm (0.003 in)

Exhaust : 0.09 mm (0.004 in)

SEM008A

SEM931C