Nissan Frontier. Manual - part 719

OIL SEAL

EM-65

< REMOVAL AND INSTALLATION >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

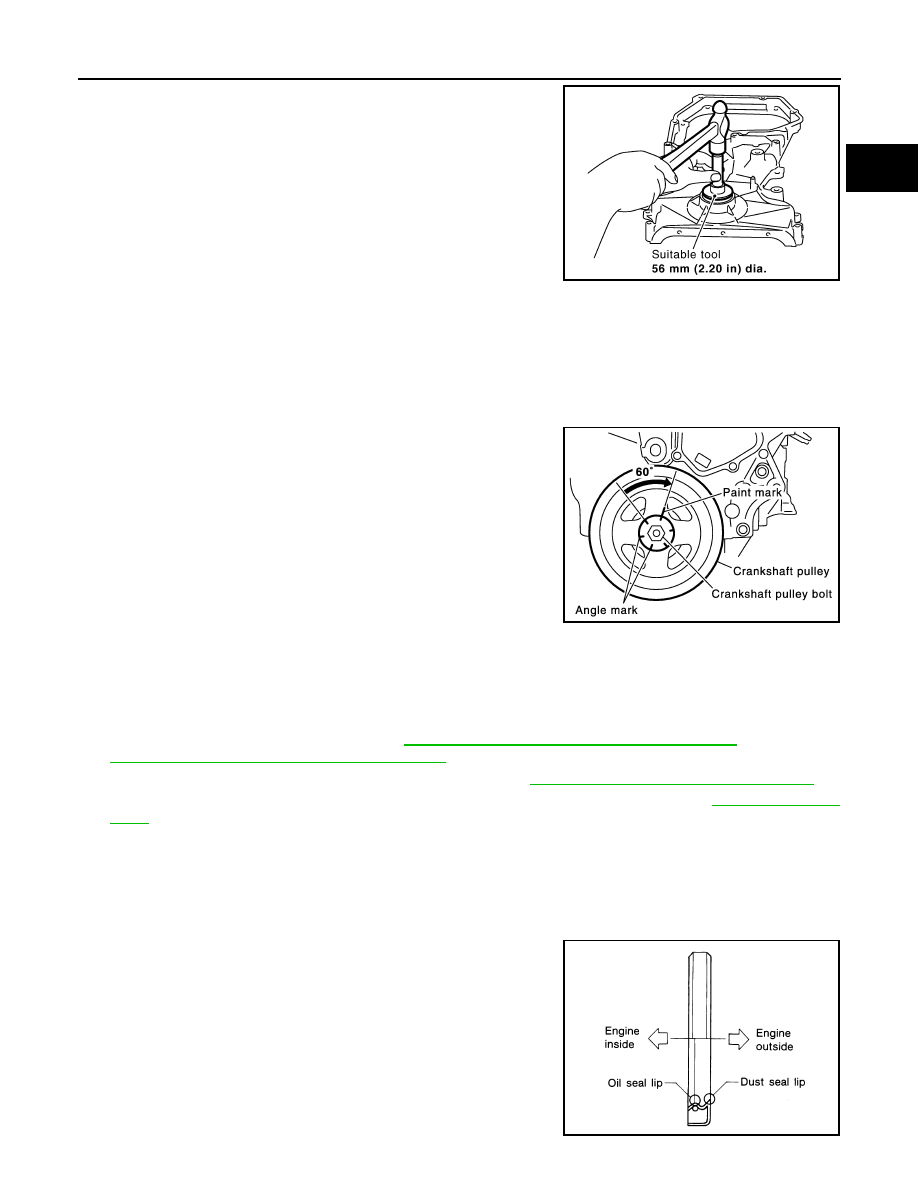

• Press-fit front oil seal until it is flush with front end surface of

front cover using suitable tool.

CAUTION:

• Be careful not to damage front cover and crankshaft.

• Press-fit straight and avoid causing burrs or tilting oil

seal.

3. Tighten crankshaft pulley bolt.

• Secure crankshaft pulley using suitable tool, and tighten crankshaft pulley bolt.

a. Apply new engine oil to thread and seat surfaces of crankshaft pulley bolt.

b. Tighten crankshaft pulley bolt.

c. Put a paint mark on crankshaft pulley, mating with any one of six

easy to recognize angle marks on bolt flange.

d. Turn another 60

° degrees clockwise (angle tightening).

• Check the tightening angle with movement of one angle mark.

4. Installation is in the reverse order of removal after this step.

Removal and Installation of Rear Oil Seal

INFOID:0000000009478070

REMOVAL

1. Remove transmission assembly. Refer to

TM-21, "Removal and Installation from Vehicle"

TM-306, "Removal and Installation for QR25DE"

2. Remove clutch cover and clutch disk (M/T models). Refer to

CL-19, "5M/T : Removal and Installation"

3. Remove drive plate (A/T models) or flywheel (M/T models) with power tool. Refer to

.

4. Remove rear oil seal with a suitable tool.

CAUTION:

Be careful not to damage crankshaft and cylinder block.

INSTALLATION

1. Apply new engine oil to new rear oil seal joint surface and seal lip.

2. Install rear oil seal so that each seal lip is oriented as shown.

PBIC3033E

Crankshaft pulley bolt

: 42.1 N·m (4.3 kg-m, 31 ft-lb)

SEM751G

SEM715A