Nissan Sentra. Manual - part 907

TM-264

< REMOVAL AND INSTALLATION >

[CVT: RE0F11A]

AIR BREATHER HOSE

AIR BREATHER HOSE

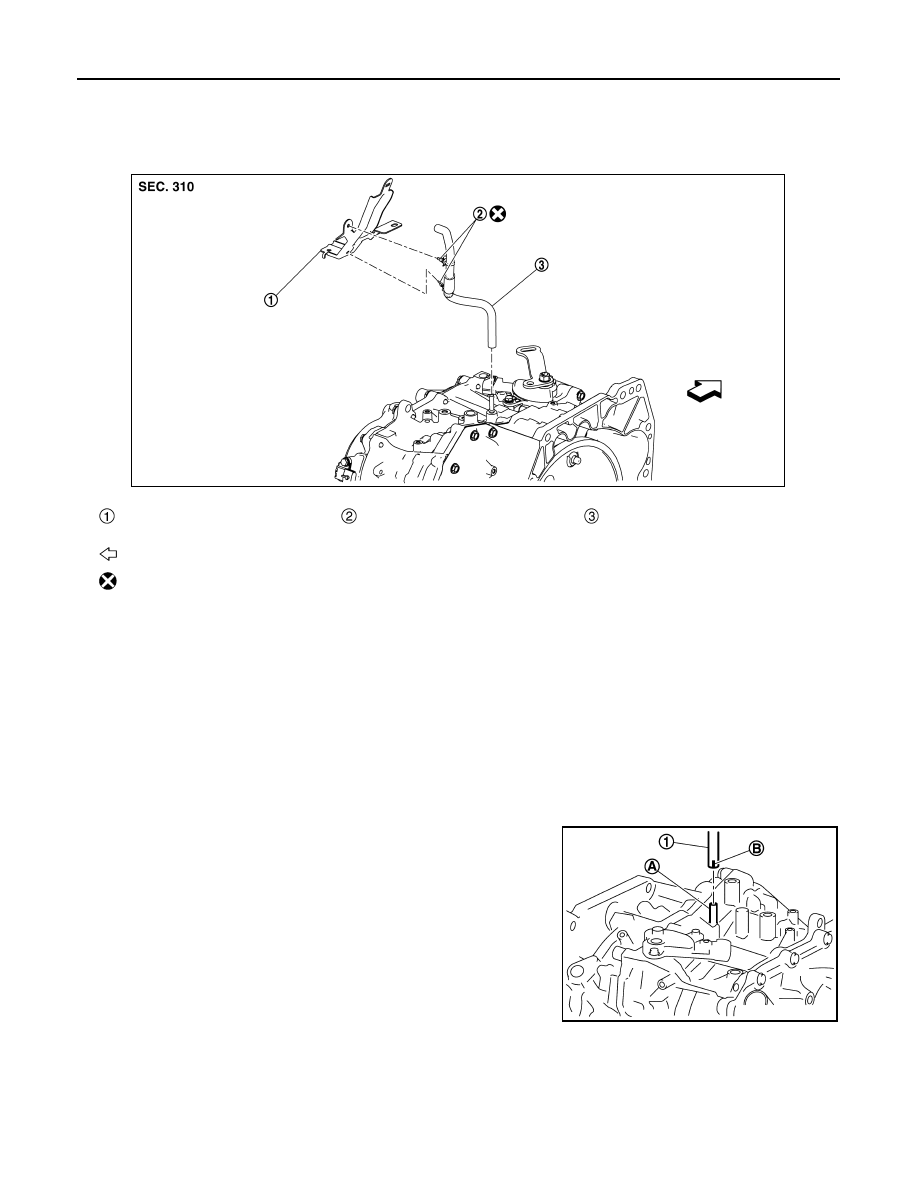

Exploded View

INFOID:0000000009759511

Removal and Installation

INFOID:0000000009759512

REMOVAL

1. Remove clips from harness bracket.

2. Remove air breather hose from transaxle assembly.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not bend the air breather hose to prevent damage to the hose.

• Do not reuse clips.

• Securely install the clips to the harness bracket.

• Be sure to insert it fully until its end reaches the stop when

inserting air breather hose (1) to transaxle tube (A).

• Install air breather hose to transaxle tube so that the paint

mark (B) is facing frontward.

Harness bracket

.

Clip

.

Air breather hose

: Vehicle front

: Always replace after every disassembly.

JSDIA3584ZZ

JSDIA1887ZZ