Nissan Sentra. Manual - part 852

TM-44

< UNIT DISASSEMBLY AND ASSEMBLY >

[6MT: RS6F94R]

TRANSAXLE ASSEMBLY

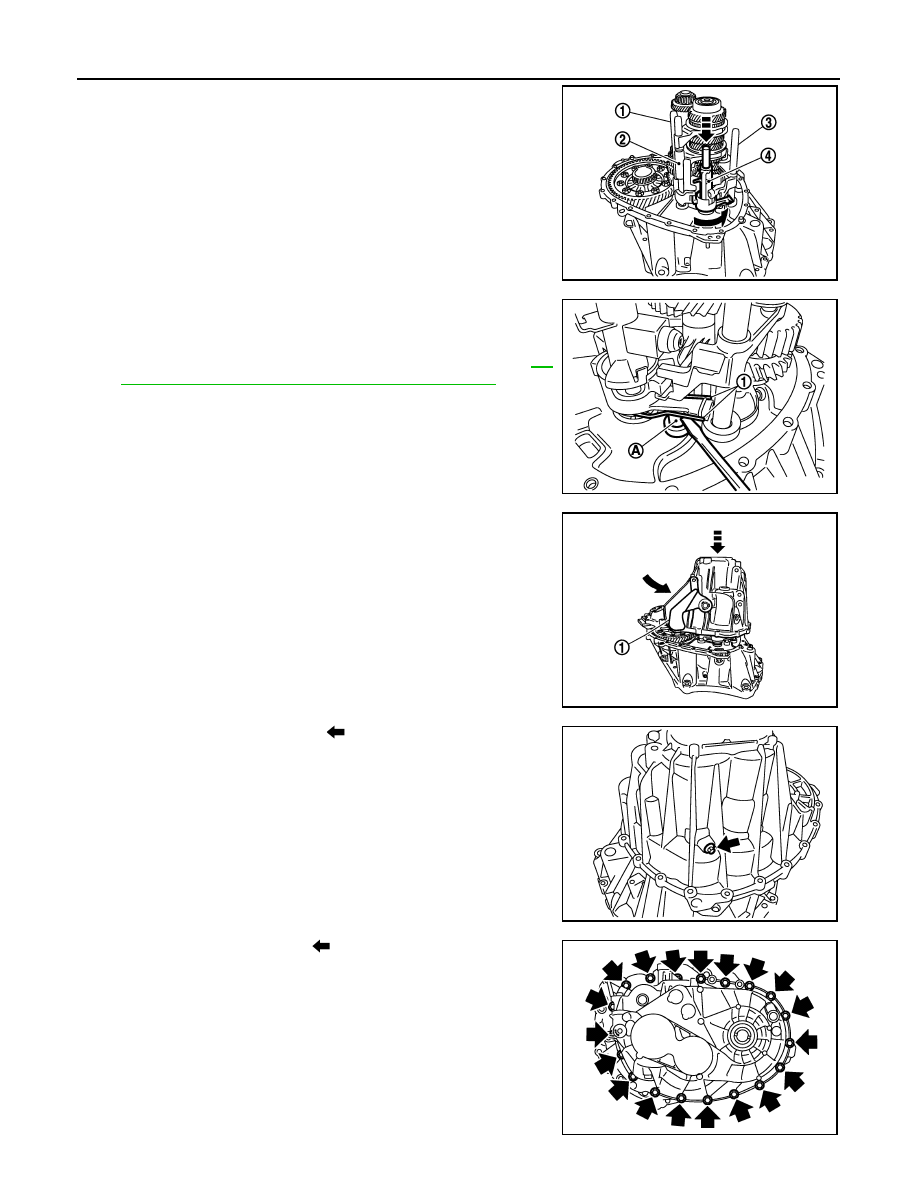

23. Move 1st-2nd fork rod (1), fork rod (2), and reverse fork rod (3)

to the neutral position.

24. Install selector (4) to clutch housing.

CAUTION:

Replace selector lever and selector as a set.

25. Install selector spring (1) to return bushing (A).

26. Apply recommended sealant to the gasket surface of transaxle

case.

• Use Genuine Silicone RTV or an equivalent. Refer to

21, "Recommended Chemical Products and Sealants"

.

CAUTION:

• Do not allow old liquid gasket, moisture, oil, or foreign

matter to remain on gasket surface.

• Check that the gasket surface is not damaged.

• Apply sealant bead continuously.

27. Install transaxle case to clutch housing while rotating shifter

lever A (1) in the direction as shown.

28. Install reverse idler shaft bolt (

), as per the following proce-

dure.

a. Install sealing washer to reverse idler shaft bolt, and install

reverse idler shaft bolt to transaxle case.

CAUTION:

Do not reuse sealing washer.

b. Tighten reverse idler shaft bolt to the specified torque.

29. Tighten transaxle case bolts (

) to the specified torque.

SCIA7782E

JPDIC0445ZZ

JPDIC0110ZZ

PCIB1695E

PCIB1694E