Nissan Frontier D22. Manual - part 438

DTC P0300 - P0306 MULTIPLE CYLINDER MISFIRE, NO. 1 - 6 CYLINDER MIS-

FIRE

EC-855

[VG33E]

C

D

E

F

G

H

I

J

K

L

M

A

EC

12.

CHECK HEATED OXYGEN SENSOR 1

With CONSULT-II

1.

Start engine and warm it up to normal operating temperature.

2.

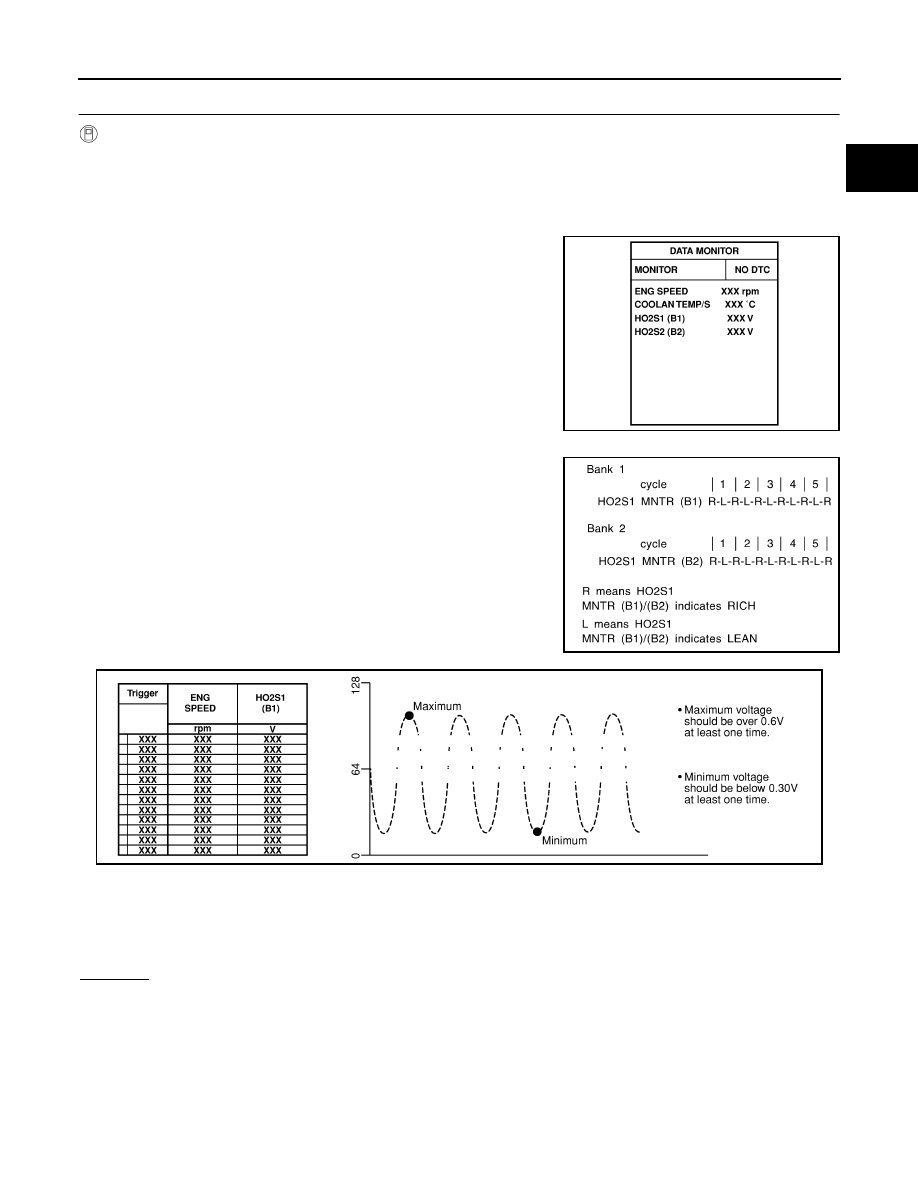

Select “MANU TRIG” and “HI SPEED” in “DATA MONITOR” mode with CONSULT-II, and select “HO2S1

(B1)/(B2)” and “HO2S1 MNTR (B1)/(B2)”.

3.

Hold engine speed at 2,000 rpm under no load during the following steps.

4.

Touch “RECORD” on CONSULT-II screen.

5.

Check the following.

–

“HO2S1 MNTR (B1)/(B2)” in “DATA MONITOR” mode changes

from “RICH” to “LEAN” to “RICH” more than 5 times in 10 sec-

onds.

5 times (cycles) are counted as shown left:

–

“HO2S1 (B1)/(B2)” voltage goes above 0.6V at least once.

–

“HO2S1 (B1)/(B2)” voltage goes below 0.3V at least once.

–

“HO2S1 (B1)/(B2)” voltage never exceeds 1.0V.

CAUTION:

●

Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

●

Before installing new oxygen sensor, clean exhaust system threads using Oxygen Sensor Thread

Cleaner tool J-43897-18 or J-43897-12 and approved anti-seize lubricant.

OK or NG

OK

>> GO TO 14.

NG

>> Replace malfunctioning heated oxygen sensor 1.

SEF967Y

SEF647Y

SEF648Y