Nissan Frontier D22. Manual - part 437

DTC P0300 - P0306 MULTIPLE CYLINDER MISFIRE, NO. 1 - 6 CYLINDER MIS-

FIRE

EC-851

[VG33E]

C

D

E

F

G

H

I

J

K

L

M

A

EC

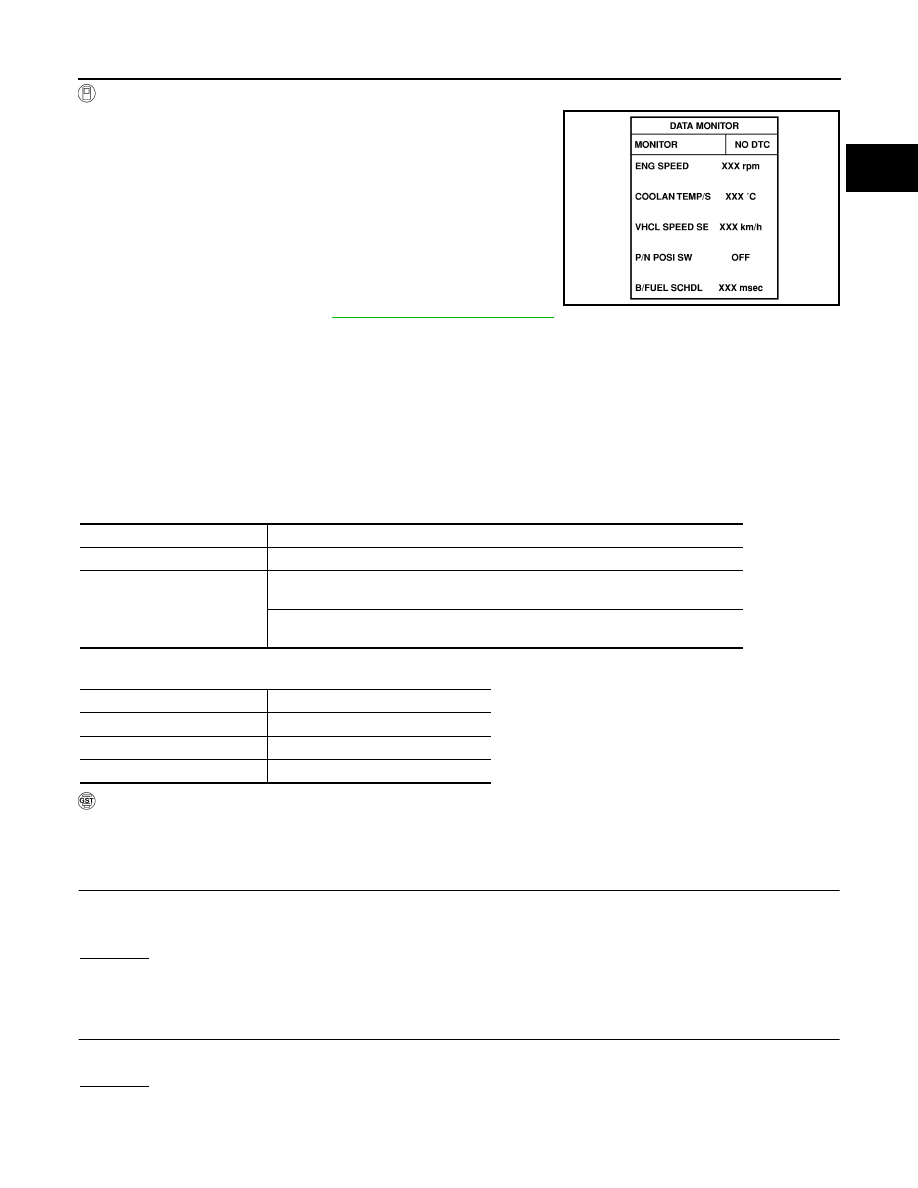

WITH CONSULT-II

1.

Turn ignition switch ON, and select “DATA MONITOR” mode

with CONSULT-II.

2.

Start engine and warm it up to normal operating temperature.

3.

Turn ignition switch OFF and wait at least 5 seconds.

4.

Start engine again and drive at 1,500 to 3,000 rpm for at least 3

minutes.

Hold the accelerator pedal as steady as possible.

NOTE:

Refer to the freeze frame data for the test driving condi-

tions.

5.

If 1st trip DTC is detected, go to

EC-851, "Diagnostic Procedure"

.

NOTE:

If 1st trip DTC is not detected during above procedure, performing the following procedure is advised.

1.

Turn ignition switch OFF and wait at least 10 seconds.

2.

Start engine and drive the vehicle under the similar conditions to (1st trip) Freeze Frame Data for a certain

time. Refer to the table below.

Hold the accelerator pedal as steady as possible.

The similar conditions to (1st trip) Freeze Frame Data means the vehicle operation that the following con-

ditions should be satisfied at the same time.

The time to driving varies according to the engine speed in the freeze frame data.

WITH GST

Follow the procedure “WITH CONSULT-II”.

Diagnostic Procedure

UBS00DJG

1.

CHECK FOR INTAKE AIR LEAK

1.

Start engine and run it at idle speed.

2.

Listen for the sound of the intake air leak.

OK or NG

OK

>> GO TO 2.

NG

>> Discover air leak location and repair.

2.

CHECK FOR EXHAUST SYSTEM CLOGGING

Stop engine and visually check exhaust tube, three way catalyst and muffler for dents.

OK or NG

OK

>> GO TO 3.

NG

>> Repair or replace it.

SEF213Y

Engine speed

Engine speed in the freeze frame data

± 400 rpm

Vehicle speed

Vehicle speed in the freeze frame data

± 10 km/h (6 MPH)

Engine coolant temperature

(T) condition

When the freeze frame data shows lower than 70

°C (158 °F),

T should be lower than 70

°C (158 °F).

When the freeze frame data shows higher than or equal to 70

°C (158 °F),

T should be higher than or equal to 70

°C (158 °F).

Engine speed

Time

Around 1,000 rpm

Approximately 10 minutes

Around 2,000 rpm

Approximately 5 minutes

More than 3,000 rpm

Approximately 3.5 minutes