Nissan Frontier D22. Manual - part 436

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

EC-847

[VG33E]

C

D

E

F

G

H

I

J

K

L

M

A

EC

Be extremely careful not to touch any moving or adjacent parts.

5.

Check radiator for blocked air passage

Check for blocked condenser or radiator (condenser or radiator fins damaged, condenser or radiator

clogged), after market fog lamps ...etc. Check for condenser or radiator fin damage, shroud damage, vehi-

cle front end for clogging of debris or insects ...etc.

Check for improper fitting of front end cover, damaged radiator grille or bumper, vehicle frontal area dam-

aged by collision but not repaired.

If NG, take appropriate action and then go to next step.

6.

Check ECT sensor for proper operation. Refer to step 5 of

EC-847, "Diagnostic Procedure"

replace ECT sensor and go to next step.

7.

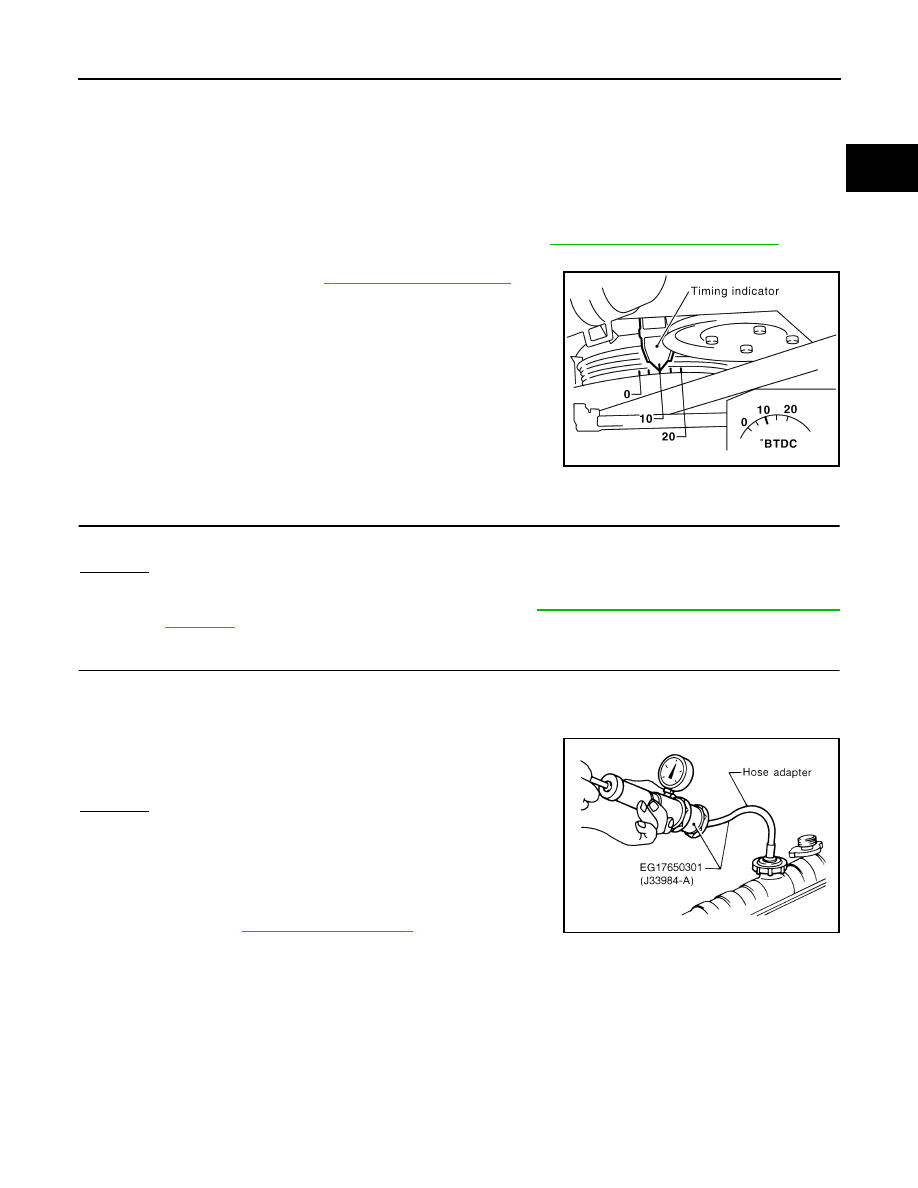

Check ignition timing. Refer to

Make sure that ignition timing is 10

± 5° at 700 ± 50 rpm.

If NG, adjust ignition timing and then recheck.

Diagnostic Procedure

UBS00DJC

1.

CHECK COOLING FAN (CRANKSHAFT DRIVEN) OPERATION

Start engine and make sure that cooling fan (crankshaft driven) operates.

OK or NG

OK

>> GO TO 2.

NG

>> Check cooling fan (crankshaft driven). Refer to

CO-32, "COOLING FAN (CRANKSHAFT

2.

CHECK COOLING SYSTEM FOR LEAK

Apply pressure to the cooling system with a tester, and check if the pressure drops.

CAUTION:

Higher than the specified pressure may cause radiator damage.

Pressure should not drop.

OK or NG

OK

>> GO TO 3.

NG

>> Check the following for leak:

●

Hose

●

Radiator

●

Water pump

Refer to

SEF927Z

Testing pressure: 157 kPa (1.6 kg/cm

2

, 23 psi)

SLC754A