Nissan Frontier D22. Manual - part 439

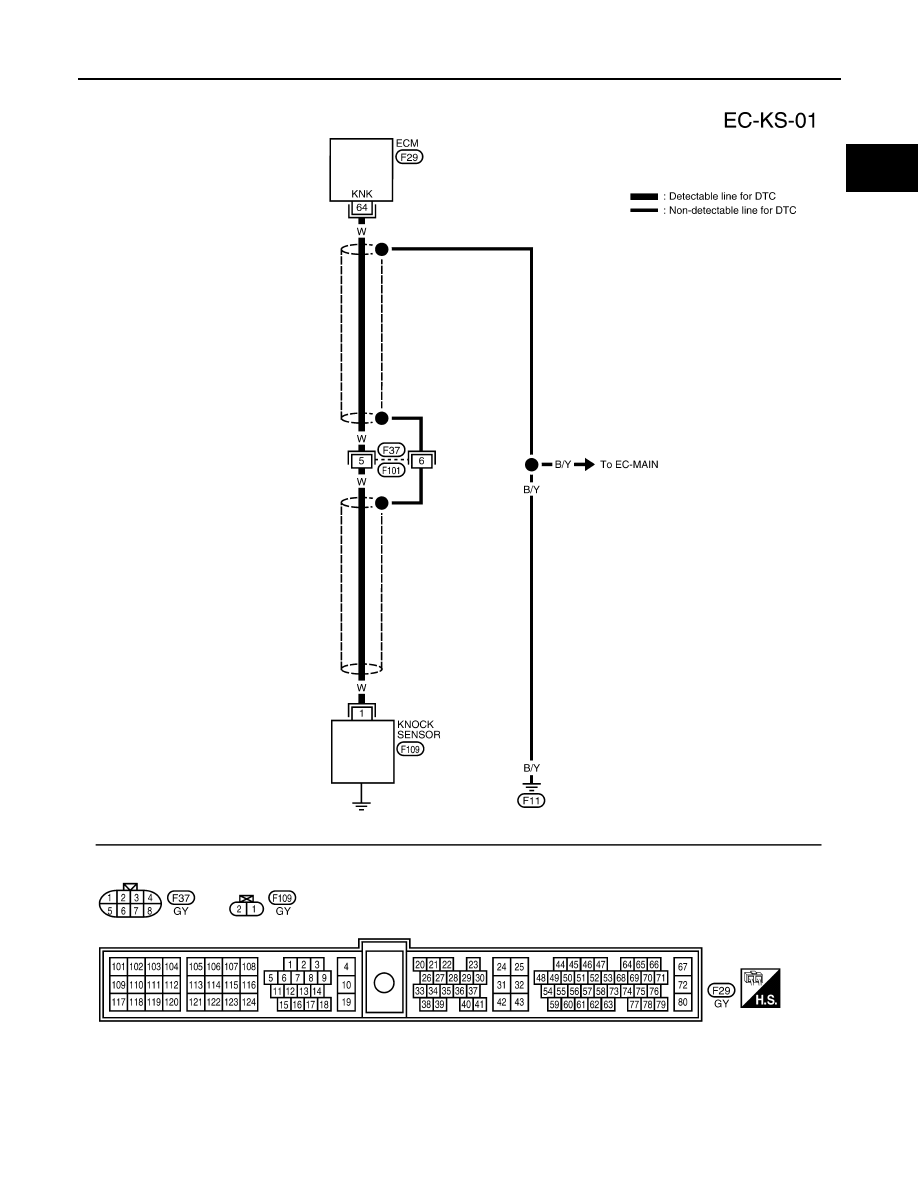

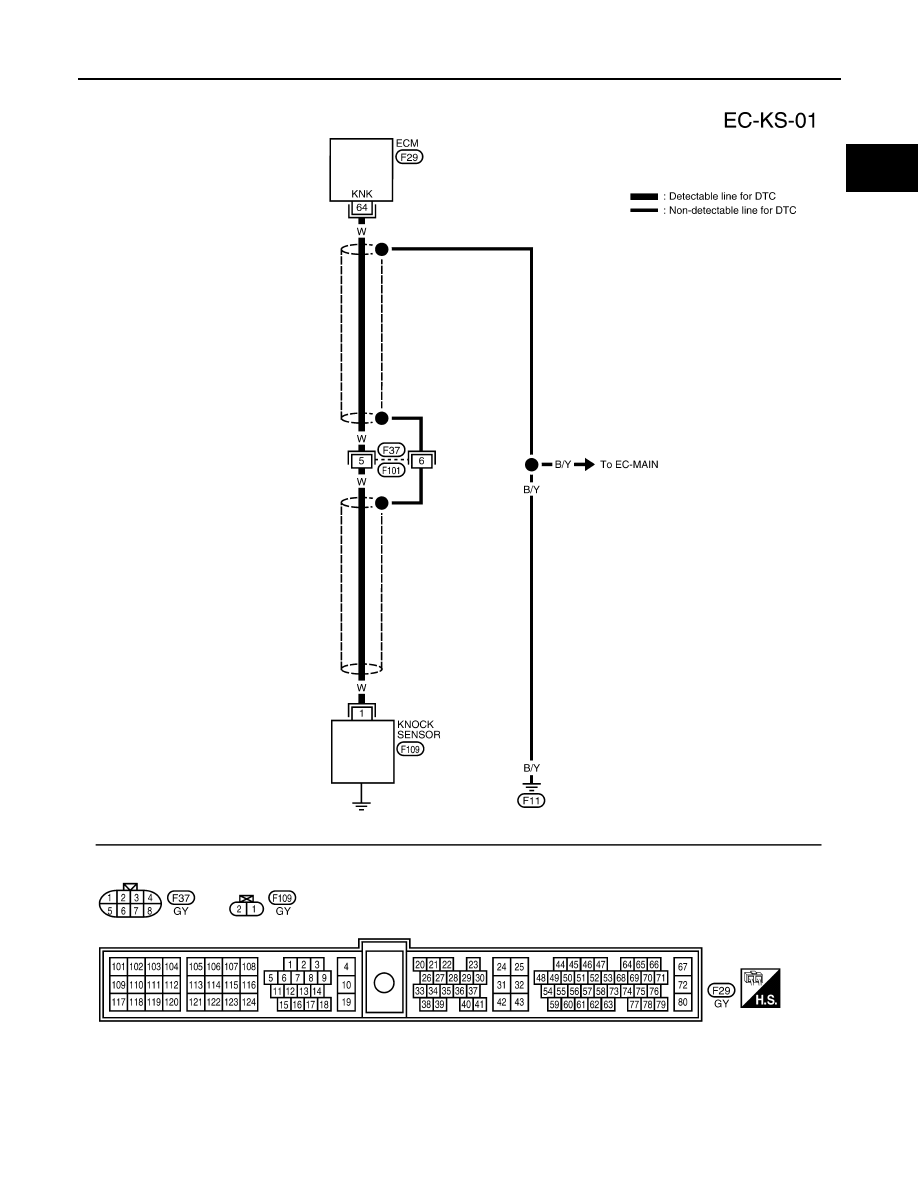

DTC P0327, P0328 KS

EC-859

[VG33E]

C

D

E

F

G

H

I

J

K

L

M

A

EC

Wiring Diagram

UBS00DJK

BBWA0480E

|

|

|

DTC P0327, P0328 KS EC-859 [VG33E] C D E F G H I J K L M A EC Wiring Diagram UBS00DJK BBWA0480E |