Nissan Xterra. Manual - part 431

FAX-14

< UNIT DISASSEMBLY AND ASSEMBLY >

DRIVE SHAFT

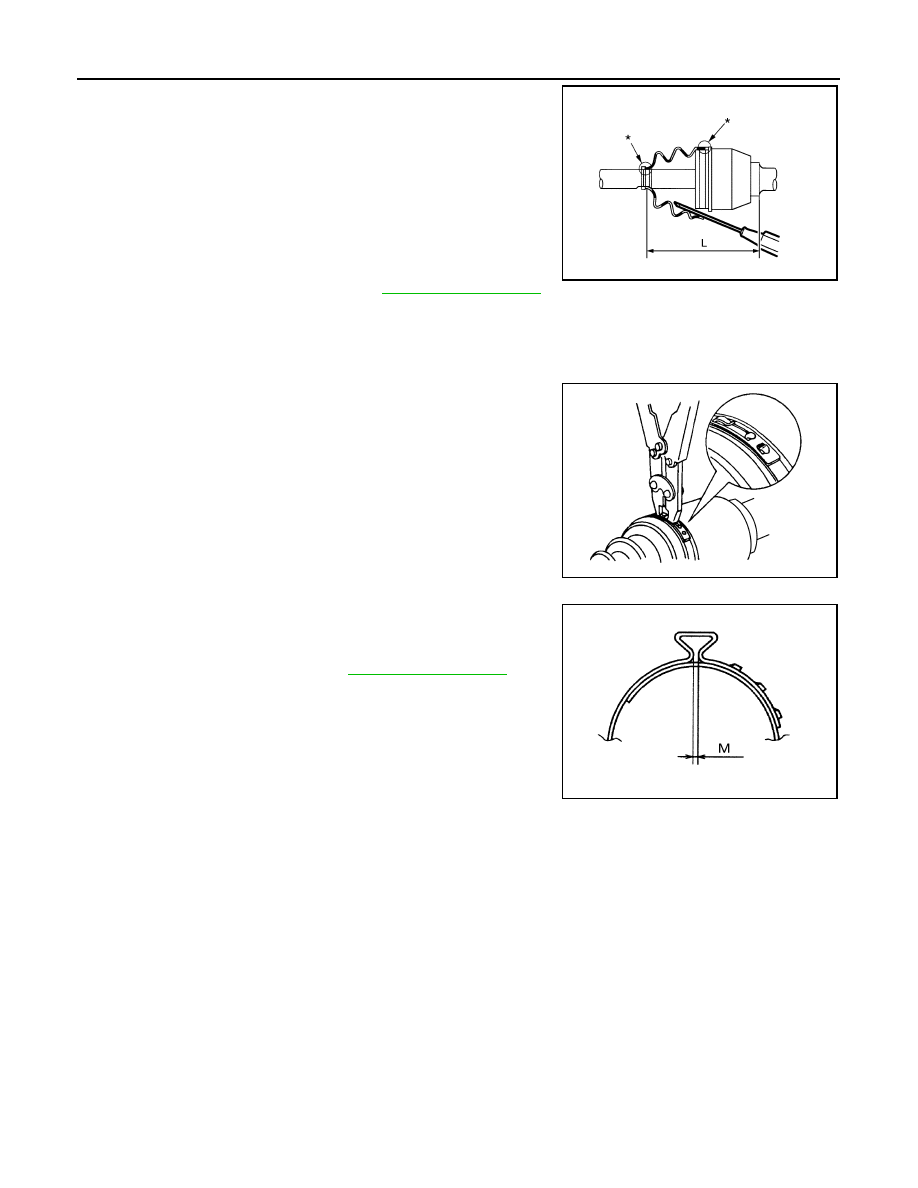

6. Install the boot securely into the grooves (indicated by the *

marks) as shown.

CAUTION:

If there is grease on the boot mounting surfaces (indicated

by the * marks) of the shaft and joint sub-assembly, the

boot may come off. Remove all grease from the drive shaft

surfaces.

7. Check that the boot installation length (L) is the specified length.

Insert a suitable tool into the large end of the boot. Bleed the air

from the boot to prevent boot deformation.

CAUTION:

• The boot may break if the boot installation length is less than the specified length.

• Do not contact inside surface of boot with the tip of the suitable tool.

8. Secure large and small ends of the boot using new boot bands

using tool as shown.

CAUTION:

Do not reuse boot bands.

• Secure boot band so that dimension (M) meets specification

as shown.

9. After installing the housing to the shaft, rotate the boot to check

that it is positioned correctly. If the boot is not positioned cor-

rectly, remove the old boot bands then reposition the boot and

secure the boot with new boot bands.

Boot installation

length (L)

Tool number : KV40107300 ( — )

JPDIF0142ZZ

RAC1133D

Dimension (M)

: Refer to

.

DSF0047D