Nissan Xterra. Manual - part 430

FAX-10

< UNIT DISASSEMBLY AND ASSEMBLY >

DRIVE SHAFT

UNIT DISASSEMBLY AND ASSEMBLY

DRIVE SHAFT

Disassembly and Assembly

INFOID:0000000009484366

DISASSEMBLY

Final Drive Side

1. Mount the drive shaft in a vise.

CAUTION:

When mounting the drive shaft in a vise, use copper or aluminum plates between the vise and the

drive shaft.

2. Remove boot bands and slide the boot back.

3. Put matching marks on housing and shaft before separating joint assembly.

CAUTION:

Use paint or similar substance for matching marks. Do not scratch the surfaces.

4. Remove the stopper ring with a suitable tool as shown, and pull

the housing off.

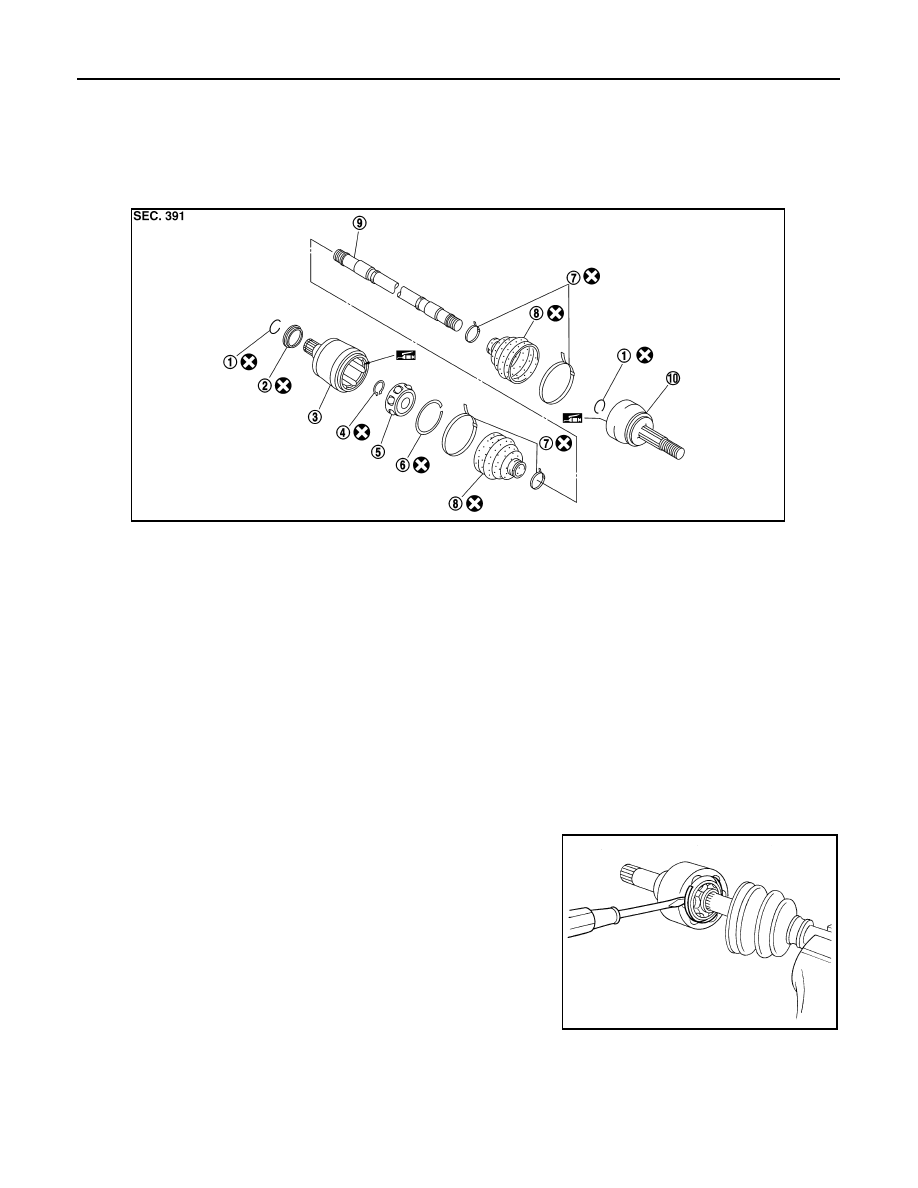

1.

Circlip

2.

Dust cover

3.

Housing

4.

Snap ring

5.

Ball cage, steel ball and inner race assembly

6.

Stopper ring

7.

Boot band

8.

Boot

9.

Shaft

10.

Joint sub-assembly

WDIA0342E

SFA476