Nissan March K13. Manual - part 650

AIR BREATHER HOSE

TM-17

< REMOVAL AND INSTALLATION >

[5MT: RS5F91R]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

AIR BREATHER HOSE

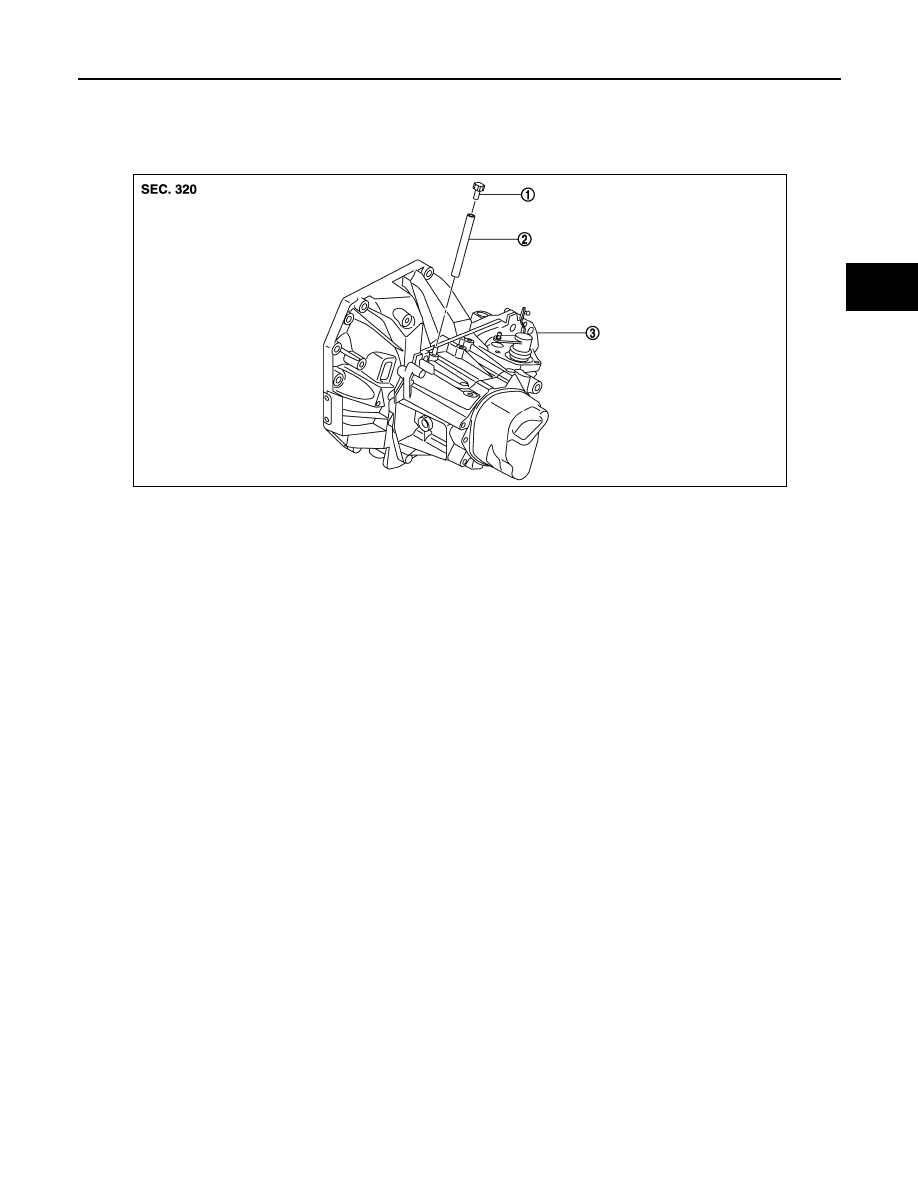

Exploded View

INFOID:0000000006056573

Removal and Installation

INFOID:0000000006056574

REMOVAL

1.

Remove air breather hose from the 2 way connector.

CAUTION:

When removing air breather hose, be sure to hold 2 way connector securely.

2.

Remove cap hose from air breather hose.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

• Install air breather hose, preventing crush and clogging caused by bending.

• Insert the allowance of air breather hose to the spool of the 2 way connector.

1.

Cap

2.

Air breather hose

3.

2 way connector

JPDIC0788ZZ