Nissan March K13. Manual - part 649

SIDE OIL SEAL

TM-13

< REMOVAL AND INSTALLATION >

[5MT: RS5F91R]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

REMOVAL AND INSTALLATION

SIDE OIL SEAL

Removal and Installation

INFOID:0000000006056566

REMOVAL

1.

Remove front drive shafts. Refer to

FAX-17, "Removal and Installation"

.

2.

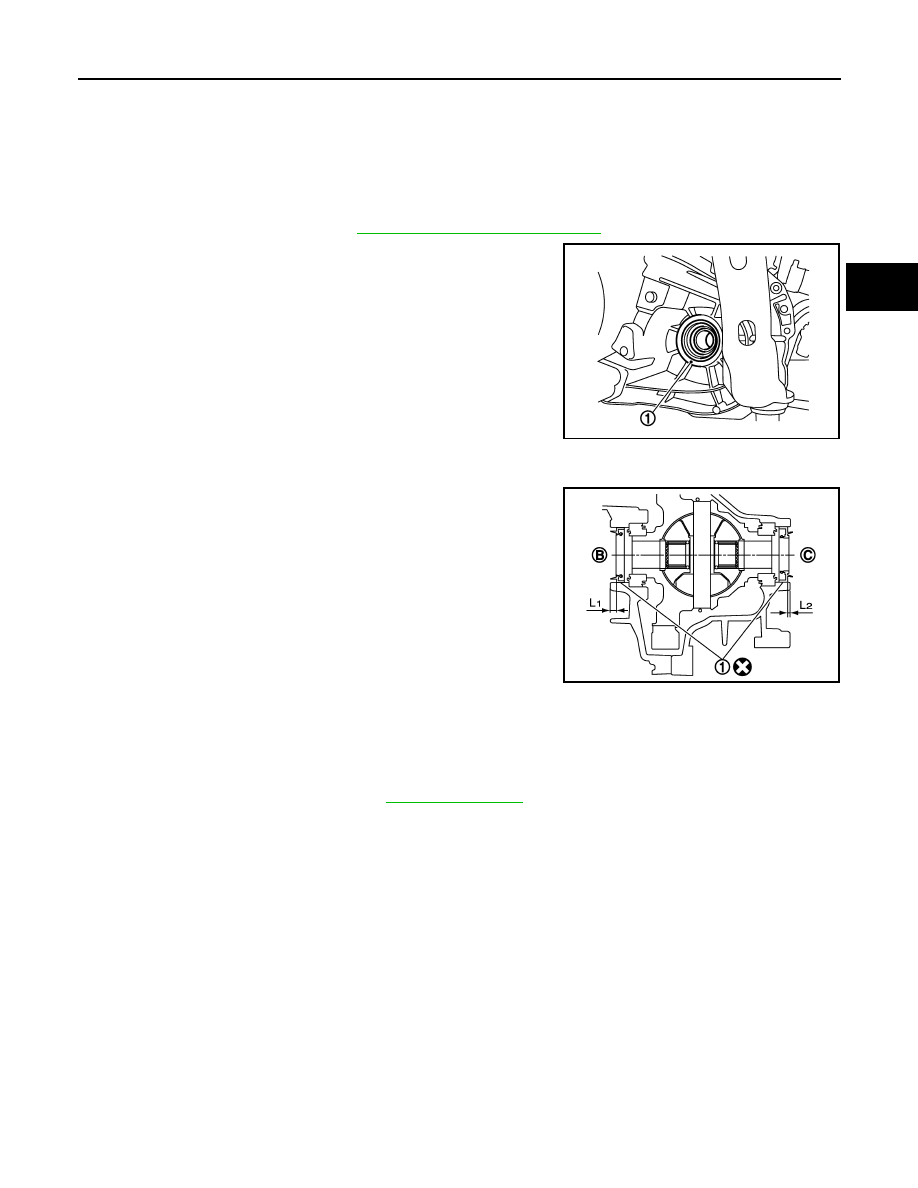

Remove differential side oil seals (1) from clutch housing and

transaxle case, using a suitable tool.

CAUTION:

Never damage transaxle case and clutch housing.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Install differential side oil seals (1) to clutch housing and transaxle

case, using the drift [Stamping number: B.vi 1666-B] of the drift set

[SST: KV32500QAA].

CAUTION:

• Never incline differential side oil seal.

• Never damage clutch housing and transaxle case.

Inspection

INFOID:0000000006056567

INSPECTION AFTER INSTALLATION

Check the oil level and oil leakage. Refer to

.

JPDIC0118ZZ

B

: Transaxle case side

C

: Clutch housing side

Dimension “L

1

”

: 5.7 – 6.3 mm (0.224 – 0.248 in)

Dimension “L

2

”

: 2.4 – 3.0 mm (0.094 – 0.118 in)

JPDIC0401ZZ