Nissan March K13. Manual - part 648

STRUCTURE AND OPERATION

TM-9

< SYSTEM DESCRIPTION >

[5MT: RS5F91R]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

STRUCTURE AND OPERATION

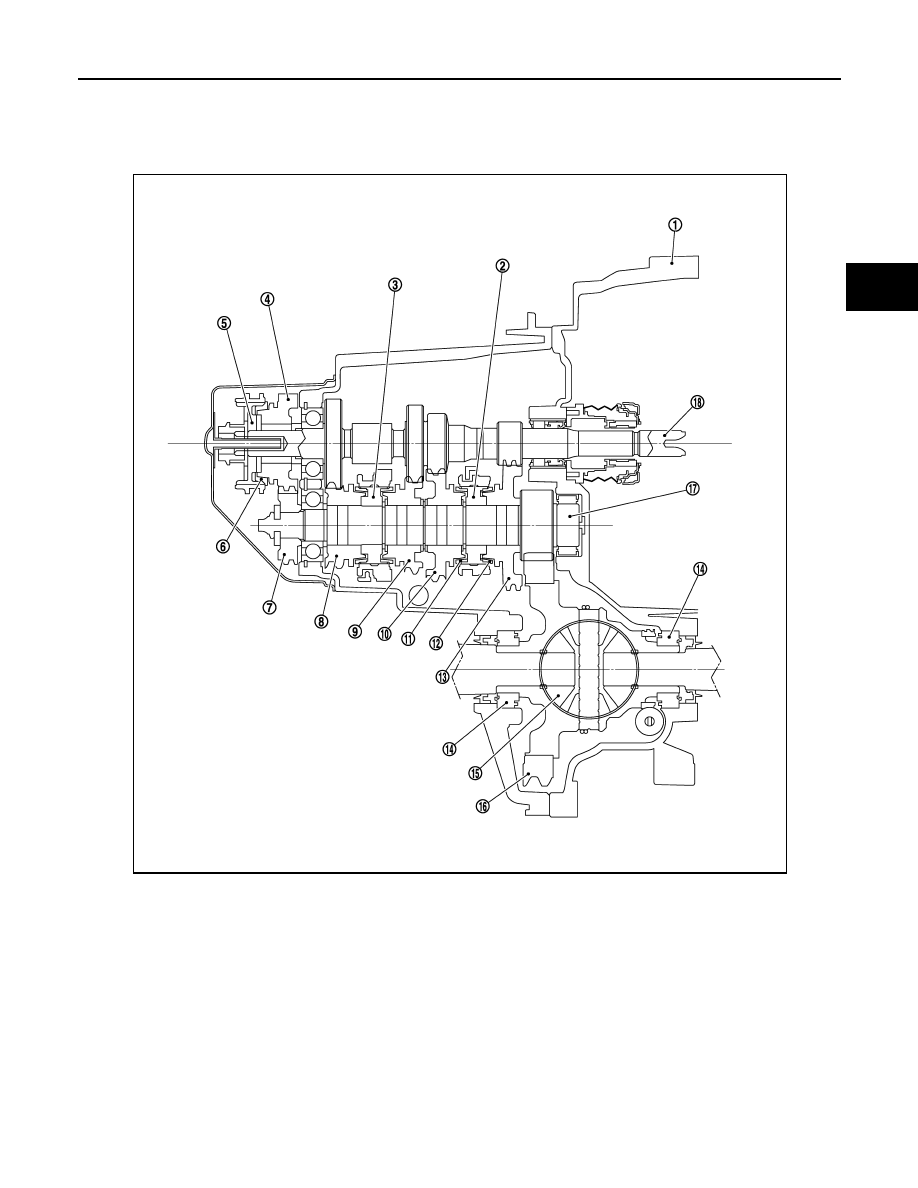

Sectional View

INFOID:0000000006056559

1.

Clutch housing

2.

1st-2nd synchronizer hub assembly

3.

3rd-4th synchronizer hub assembly

4.

5th input gear

5.

5th-reverse synchronizer hub as-

sembly

6.

5th baulk ring

7.

5th main gear

8.

4th main gear

9.

3rd main gear

10. 2nd main gear

11.

2nd single cone synchronizer

12. 1st single cone synchronizer

13. 1st main gear

14. Differential side bearing

15. Differential

16. Final gear

17. Mainshaft

18. Input shaft

JPDIC0580ZZ