Nissan March K13. Manual - part 282

EM-62

< REMOVAL AND INSTALLATION >

[HR12DE]

CAMSHAFT

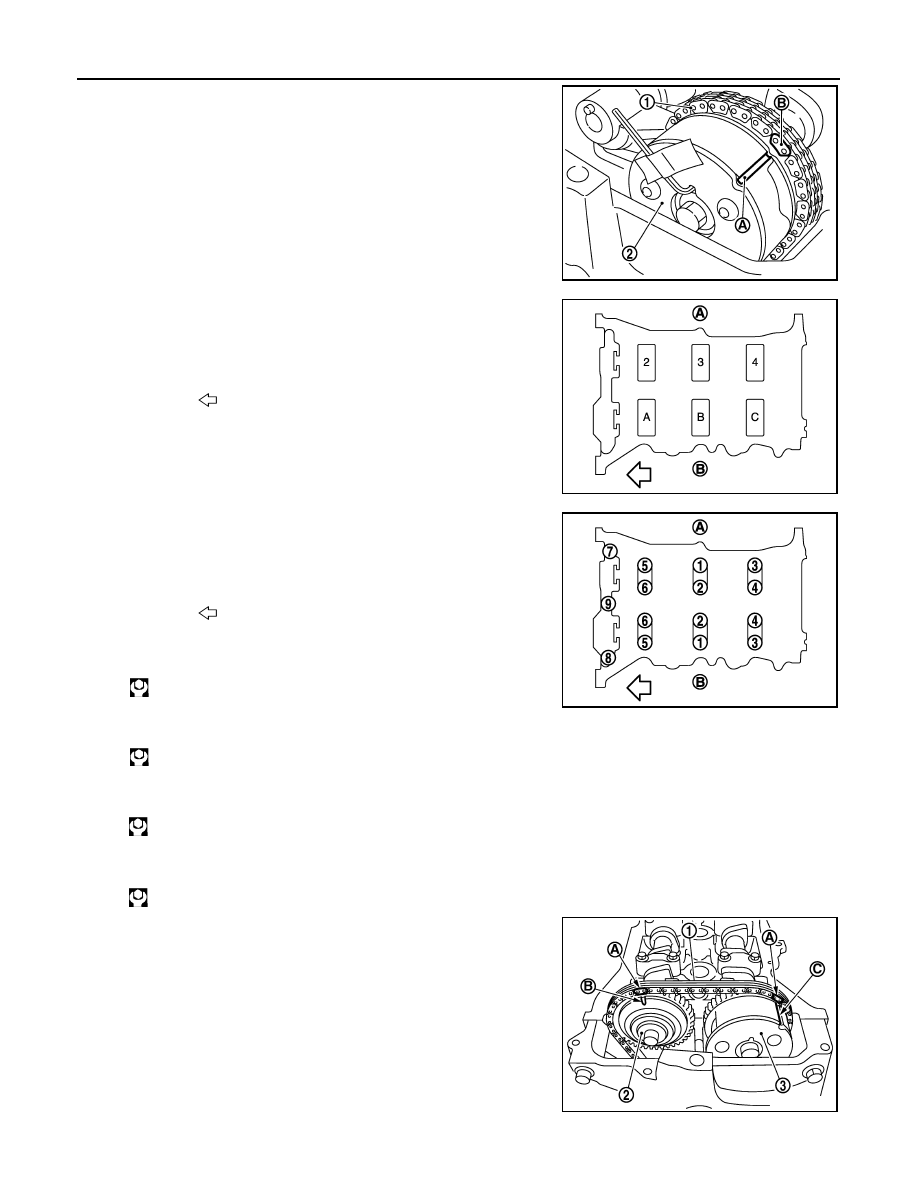

11. Install timing chain (1) by aligning its matching mark (marked

when timing chain is removed) (B) with matching mark (periph-

eral stamp line) (A) on camshaft sprocket (INT) (2).

12. Install camshaft brackets (No. 2 to 4) aligning the identification

marks on upper surface as shown in the figure.

• Install so that identification mark can be correctly read when

viewed from the INT side.

13. Tighten mounting bolts of camshaft brackets in the following

steps, in numerical order as shown in the figure.

a.

Tighten No. 7 to 9 in numerical order.

b.

Tighten No. 1 to 6 in numerical order.

c.

Tighten all bolts in numerical order.

d.

Tighten all bolts in numerical order.

14. Install the camshaft (EXH) to the camshaft sprocket (EXH) (2)

while aligning the matching mark (marked when timing chain is

removed) (A) and the matching mark (stamp) (B) of camshaft

sprocket (EXH).

• If the positions of knock pin and pin groove are not aligned,

move the camshaft (EXH) slightly to correct these positions.

PBIC3702E

A

: EXH side

B

: INT side

: Engine front

JPBIA3368ZZ

A

: EXH side

B

: INT side

: Engine front

: 2.0 N·m (0.2 kg-m, 1 ft-lb)

: 2.0 N·m (0.2 kg-m, 1 ft-lb)

: 5.9 N·m (0.6 kg-m, 4 ft-lb)

: 10.4 N·m (1.1 kg-m, 8 ft-lb)

1

: Timing chain

3

: Camshaft sprocket (INT)

C

: Matching mark (peripheral stamp line)

JPBIA3369ZZ

PBIC3674E